SENDING DATA TO A COMPUTER

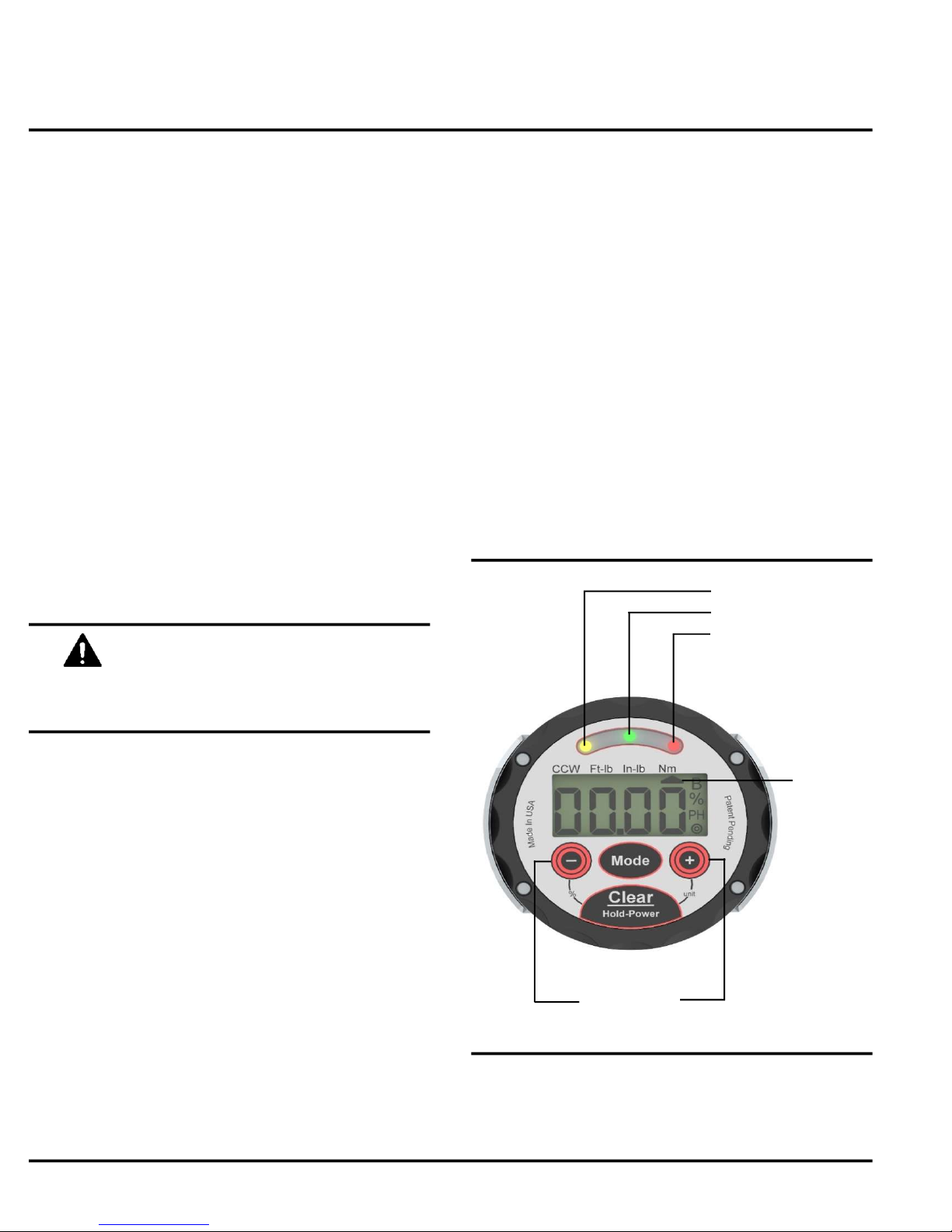

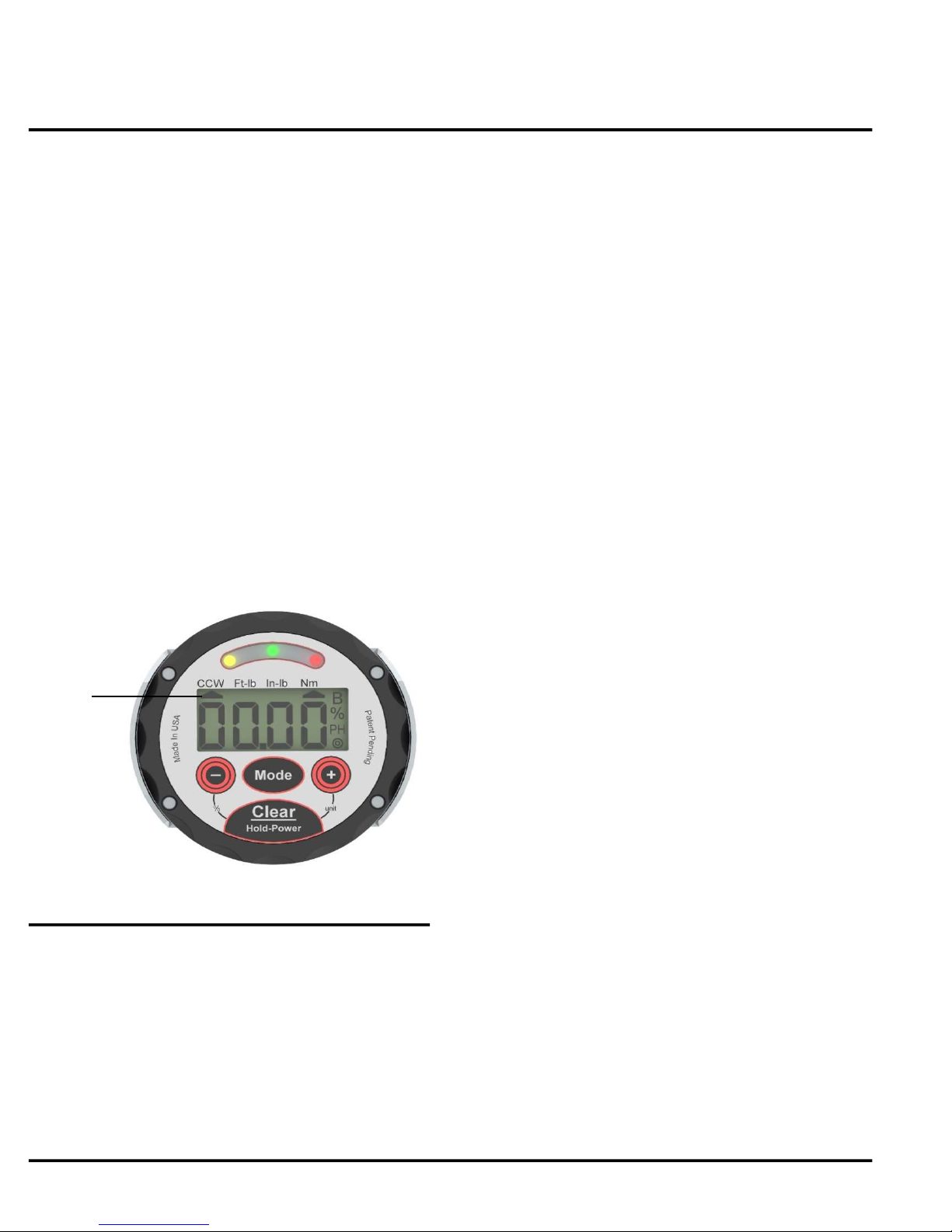

Fig. 9

Fig. 10

Jetco Torque Tools

OPERATION OF POWER WRENCHES

7 www.itorque.com

■ Connect the data/power cable to the wrench.

■ RS232 Kit only: Connect the 110V transformer to

a wall outlet and batteries will begin to charge.

■ USB Kit only: Connect the USB cable to the USB

wall transformer or USB port on a computer and

batteries will begin to charge.

NOTE:

■ The wrench can be used while charging batteries

or on external power without batteries.

■ Batteries can be charged while sending data to a

computer.

Do not install non-rechargeable batteries

in Power wrenches ("-P" and "-USB"

models) or damage will occur.

NOTE:

■ To send data to a computer, the computer must

be equipped with software capable of capturing the

data sent by the wrench.

■ The following are some programs that are

recommended for this task:

- HyperTerminal (Included in some versions of

Windows)

- DATASNIP (free download)

- Winwedge or Winwedge Pro

Please contact JETCO if you have any

questions regarding the use of software.

SENDING DATA TO A COMPUTER

■ Plug the RS232 adapter into a 9 pin serial port on

your computer or if equipped with a USB cable,

plug it into a USB port on your computer.

■ RS232 Kit only: Plug in the 110V transformer into

a wall outlet.

■ Connect the data/power cable to the wrench.

■ Turn on the wrench and set the mode to PEAK

MODE.

■ Press the CLEAR key to send data to the

computer.

NOTE:

See Figure 9 & 10

■ The following information will be sent

automatically:

- Torque value (+ for CW, - for CCW)

- Units

- Target Torque Setting

- Target Zone Setting (%)

- Low/Pass/Fail Condition

■ Data is sent in standard ASCII text format.

Communication Protocal:

9600 Bps,8 data bits, no parity, 1 stop bit

■ To send information directly to a spreadsheet or

word processor, the user can copy and paste, save

and import text files (from Hyperterminal) or

download a "wedge" program that will send data

directly. DATASNIP is recommended, visit:

www.priority1design.com.au/datasnip.html

to download a free version of DATASNIP.