17

FASTENER

13

14

15

16

17

18

19

20

21

22

23

24

P

MAX.

SPRING

PART Nº

STANDARD MANDREL - GREEN

HOLE

SIZE

1ST OVERSIZE MANDREL - YELLOW

3/32" BRIV

Brass only

1/8" BRIV

Al. Alloy,

Brass, Steel

5/32" BRIV

Al. Alloy,

Brass, Steel

5/32" BRIV

St.Steel only

3/16" BRIV

Al. Alloy,

Brass, Steel

3/16" BRIV

St.Steel only

.119

.119

.120

.120

.136

.136

.126

.126

.157

.157

.150

.150

MANDREL

PART Nº

07150-06013

07150-06013

07271-06414

07271-07414

07150-06015

07150-07015

07170-06805

07170-07805

07150-06016

07150-07016

07170-06806

07170-07806

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

HEAD

Ø

.072

.072

.092

.092

.110

.110

.120

.120

.141

.141

.153

.153

P

MAX.

HOLE

SIZE

.123

.123

.126

.126

.142

.142

.132

.132

.164

.164

.156

.156

MANDREL

PART Nº

07150-06113

07150-06113

07271-06514

07271-07514

07150-06115

07150-07115

07170-06825

07170-07825

07150-06116

07150-07116

07170-06826

07170-07826

+.004

+.004

+.005

+.005

+.005

+.005

+.005

+.005

+.005

+.005

+.005

+.005

HEAD

Ø

.076

.076

.097

.097

.115

.115

.125

.125

.146

.146

.158

.158

07170-06873

07170-06903

07150-06814

07150-07814

07170-06875

07170-07875

07170-06875

07170-07875

07170-06876

07170-07876

07170-06876

07170-07876

FASTENER

13

14

15

16

17

18

19

20

21

22

23

24

P

MAX.

SPRING

PART Nº

2ND OVERSIZE MANDREL - BLUE

HOLE

SIZE

3RD OVERSIZE MANDREL - RED

3/32" BRIV

Brass only

1/8" BRIV

Al. Alloy,

Brass, Steel

5/32" BRIV

Al. Alloy,

Brass, Steel

5/32" BRIV

St.Steel only

3/16" BRIV

Al. Alloy,

Brass, Steel

3/16" BRIV

St.Steel only

.126

.126

.133

.133

.149

.149

-

-

.170

.170

-

-

MANDREL

PART Nº

07150-06213

07150-06213

07271-06614

07271-07614

07150-06215

07150-07215

-

-

07150-06216

07150-07216

-

-

+.008

+.008

+.010

+.010

+.010

+.010

-

-

+.010

+.010

-

-

HEAD

Ø

.079

.079

.102

.102

.120

.120

-

-

.151

.151

-

-

P

MAX.

HOLE

SIZE

-

-

-

-

-

-

-

-

.173

.173

-

-

MANDREL

PART Nº

-

-

-

-

-

-

-

-

07150-06316

07150-07316

-

-

-

-

-

-

-

-

-

-

+.012

+.012

-

-

HEAD

Ø

-

-

-

-

-

-

-

-

.153

.153

-

-

07170-06873

07170-06903

07150-06814

07150-07814

07170-06875

07170-07875

-

-

07170-06876

07170-07876

-

-

REF.

Nº

REF.

Nº

BRIV IMPERIAL

For mandrel or mandrel follower spring selection, follow instructions above.

To find the correct part number of a mandrel for a particular application, read the instructions below after you have gathered the

following information as per example alongside. Answers for the example are shown in grey italic.

FASTENER NAME example Chobert

FASTENER SIZE 1/8”

DATASHEET Series 1125

APPLICATION HOLE SIZE 0.1335”

CLEARANCE BEHIND APPLICATION Infinite

‘REF.Nº’ FROM NOSE JAW SELECTION TABLE 5 (standard flat)

Subtract the minimum hole size recommended (AS REC.) in the fastener datasheet from the actual application hole size. -example: 0.005.

Turn to the page with the ‘Mandrel Selection’ table for your fastener, selecting either the imperial or the metric dimensions table

(pages 15 to 20). -example: page 15.

Starting in the ‘Standard Mandrel - Green’ section, find your fastener size in the left hand column. -example:1/8”Chobert & Grovit.

If you selected a nose jaw which can place your fastener, you should now be able to find a line within your fastener section with

the same ‘Ref. Nº’ as that from the ‘Nose Jaw Selection’ table. -example: 5.

This is your line ‘REF. Nº’ in which you will find both your mandrel and mandrel follower spring part number. This line continues

into the second half of the table for ‘2nd’ and ‘3rd’ oversize mandrels.

Scan along that line to the ‘hole size’ columns and select whichever is nearest or equal to the figure calculated in step one. You may

now read the mandrel part number next to the ‘hole size’. -example: 07150-06104.

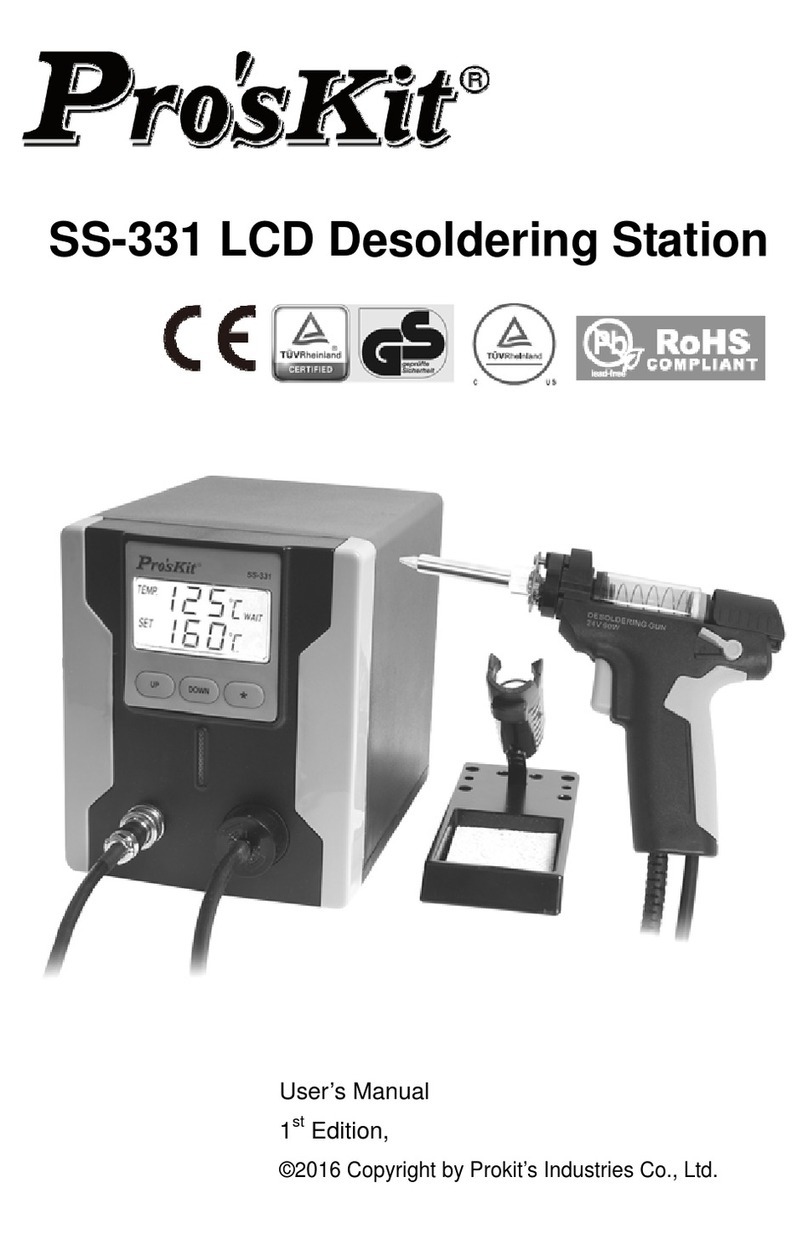

For Chobert and Grovit only, most mandrels are also available in a ‘short reach’ version (see illustration on page 18). Short reach

mandrels are used to minimise the possibility of the mandrel head contacting a rear obstruction. This would result in the underside

of the fastener head not seating properly on the application surface, causing a lack of clench in the joint.

Whichever size of mandrel you settle on, you will also need to check that the ‘P’ figure against that mandrel is adequate. ‘P’ is the

clearance required for the mandrel head at the back of the application IN ADDITION to the length of the fastener protruding through

the application, as shown in the drawing on page 18.

You may now read the corresponding mandrel follower spring part number in the right-hand column of the table. -example:07150-06804.

In all cases, satisfactory clenching of the joint should be assessed particularly if the size of the hole in your application is very close

to the next oversize hole condition, when it will be safe to select the greater size of mandrel to obtain a higher clench. REMEMBER that

this will increase the broach load and reduce the mandrel life.

■

■

■

■

■

■

■

■