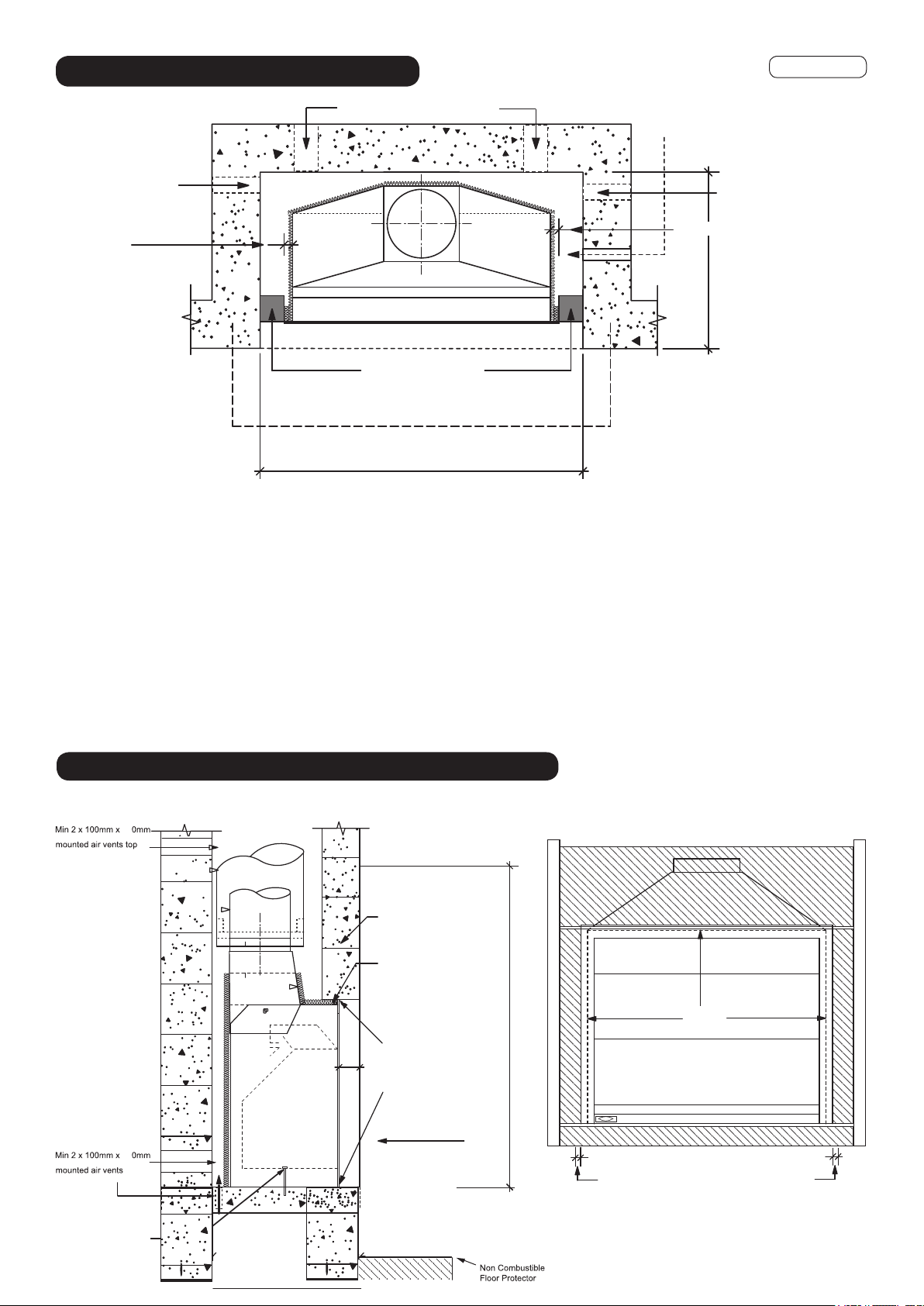

Appliance must sit on a

non-combustible base eg. 75mm

Hebel or 100mm concrete.

40mm packers are required.

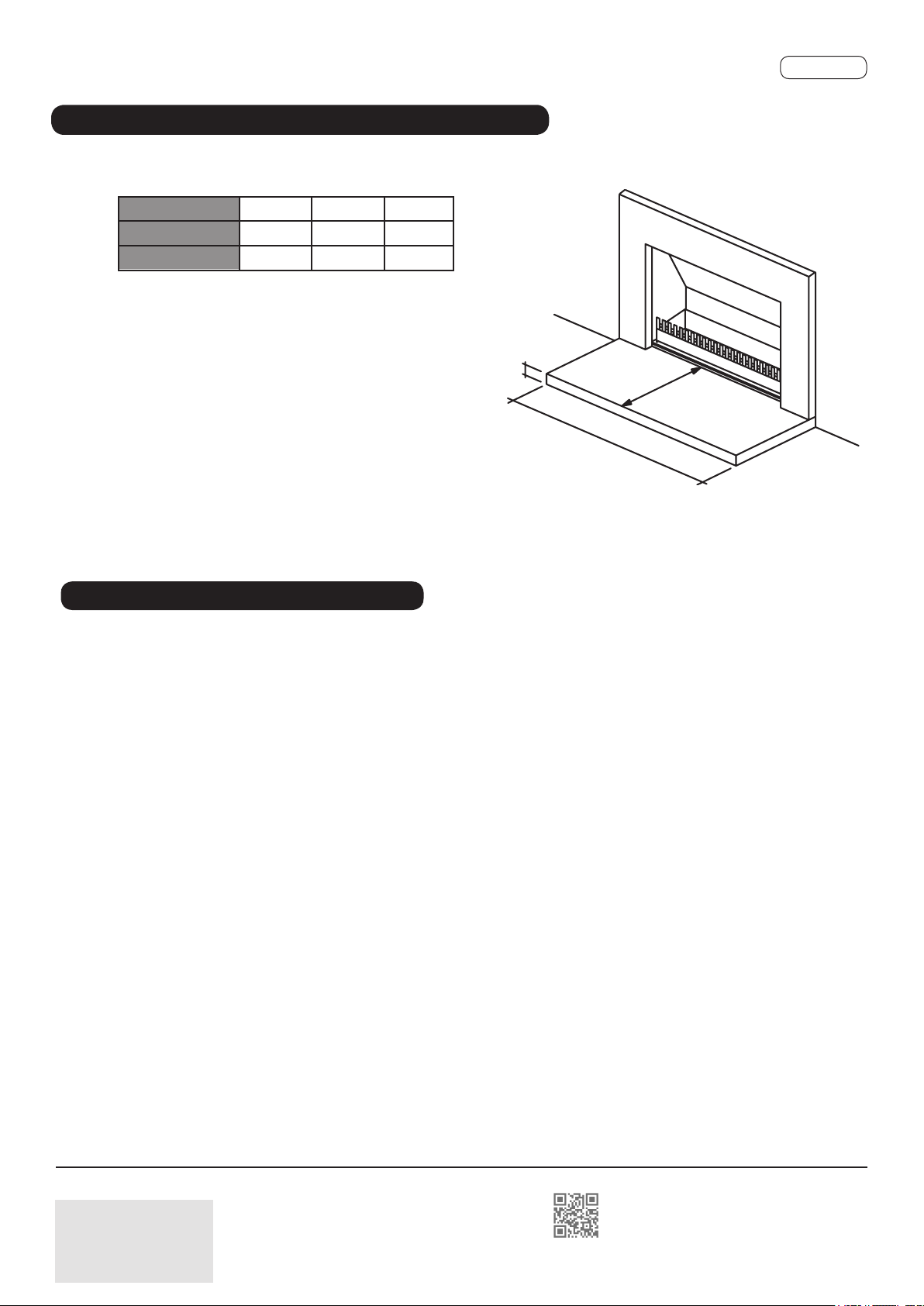

Allow 5mm gap between plaster and flange to

ensure stainless steel cover can be fitted to the box.

DO NOT PLASTER OVER THE FLANGE

FOR DETAILS OF FLOOR PROTECTION (HEARTH )

SEE PAGE 5 OF THIS DOCUMENT

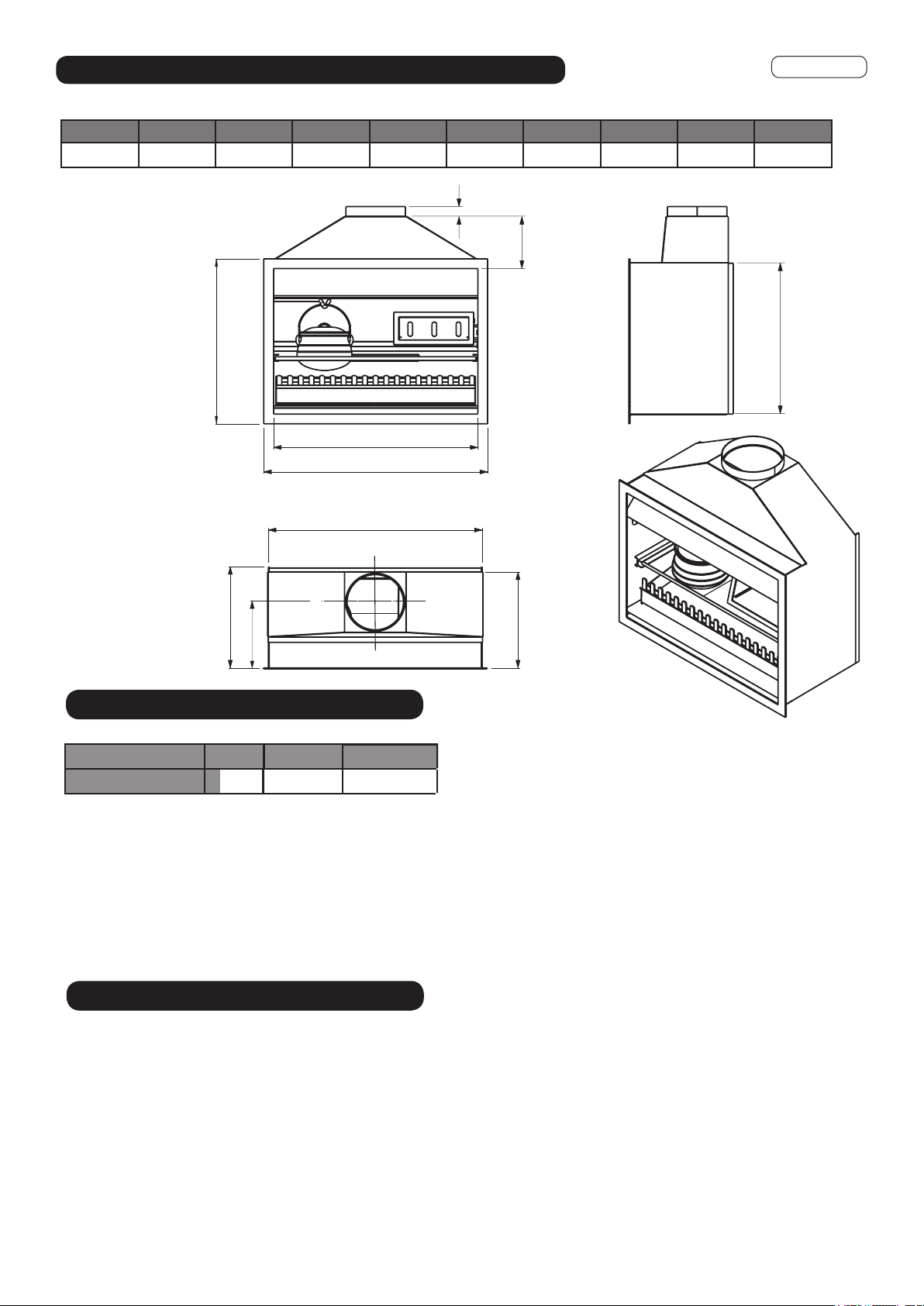

1.ODQ.3C

min. 25mm clearance 25

25 min. 25mm clearance

B + recessed

Masonry or Hebel block

minimum ‘A’

‘X’ - Refer to Table 2 for Floor Protector dimension

RECESS REQUIRED (40mm Min. 100mm Max)

‘Y’ - Refer to Table 2 for

Floor Protector dimension

Air Vent Air Vent

min. 2 x 100 x 200mm wall of floor

mounted air vents top and bottom

Jetmaster

Flange

Fig. 4

Drawings Not To Scale

Fig. 2

PLAN

CROSS SECTION

B + recessed

Concrete Lintel

Secure firebox with 2 x 6mm

dynabolts for earthquake

restraints

or Hebel Block

RECESSED REQUIRED

40mm Min. - 100mm Max recess

Rock-wool

insulation

Allow 5mm gap around all

four sides of the firebox to

fit Stainless Steel cover &

allow for firebox

expansion.

Fit 40mm Hebel packers

placed under the appliance

IMPORTANT

No combustible material into chimney chase

20

20

C- Dtemporary lintel height

*A minimum 75mm thick Floor protector is only required if finished surface is combustible e.g: timber decking

Please note that these dimensions (based on Masonry margins) are the absolute minimum sizes - widths (A & B) maybe

increased if desired.

If you intend on recessing the firebox, please add the recess value to Dimension ‘B’. MINIMUM RECESS = 40 / MAXIMUM

RECESS = 100mm

It is important to ensure the Jetmaster firebox is seated at the required finished floor protector level.

DO NOT COVER AIR VENTS WITH MESH - as this reduces air flow, use specific external air vent covers that provide sufficient

air.

Allow 5mm gap around all four sides of the firebox to fit the Stainless Steel Weather Cover. i.e. do not plaster

up to the flange of the firebox, see Fig 4.

Fig. 3

Non-combustible raised floor

protector must be 75mm Hebel

or 100mm concrete.

Appliance must sit on a

non-combustible base eg. 75mm

Hebel or 100mm concrete.

40mm packers are required