10

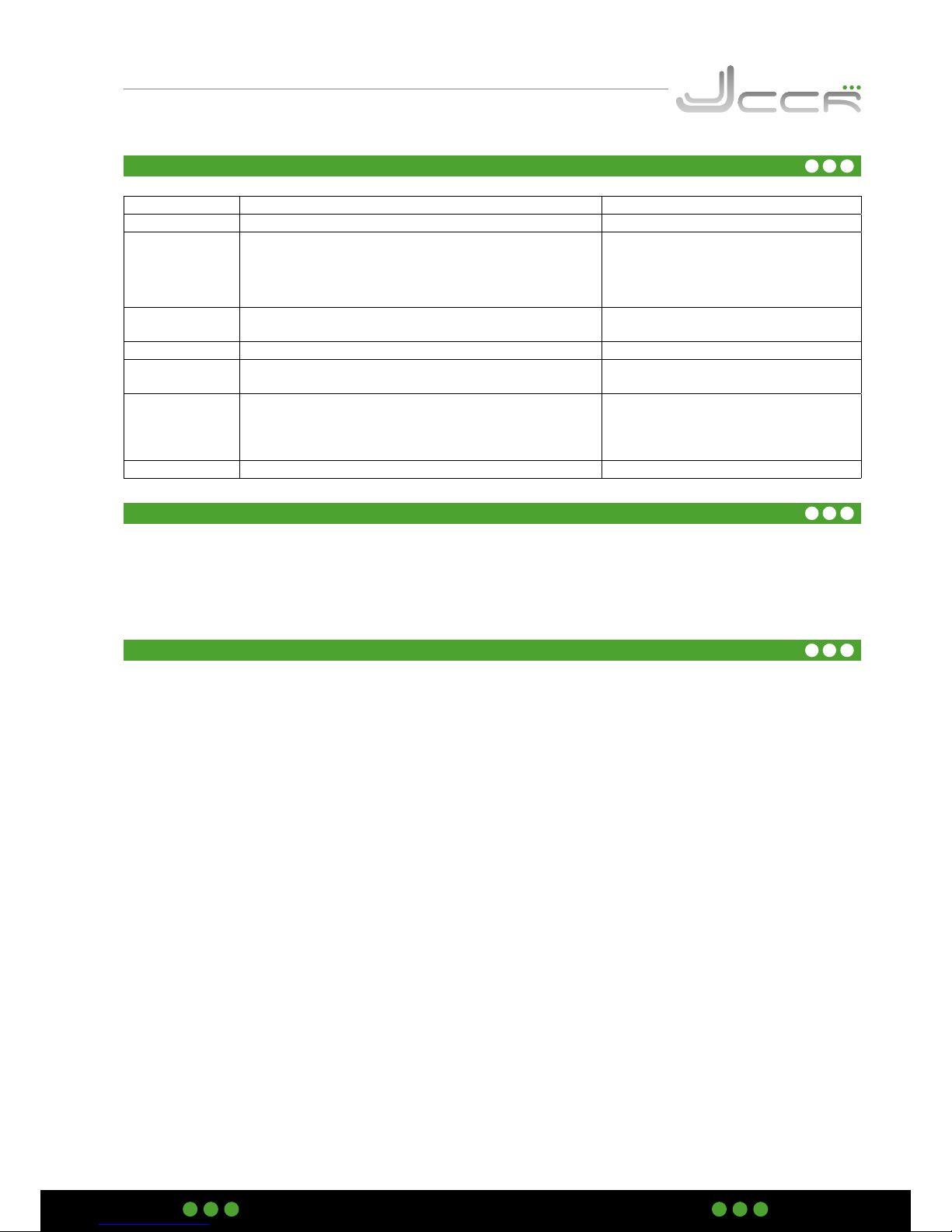

3.2 Technical specifications

Dimensions 70cm x 40cm x 26cm including the handle

Weight 34.2kg – Ready for operation with 2 x 3 litre tanks

19,8kg – Without tanks and soda lime

Soda lime canister

Type: Axial

Soda lime: Average 2.5kg (Sofnolime 797)

Running time: 180 min with dive profile (40 m)

180 min with dive profile (100 m)

Dive profile: 40 min at 40 m, 5 min at 15 m, 9 m

(40 m) for the remaining time

Dive profile: 10 min at 100 m, 1 min at 39 m, 1 min

(100 m) at 36 m, 2 min at 33 m, 2 min at 30 m,

2 min at 27 m, 3 min at 24 m, 4 min at 21 m,

4 min at 18 m, 6 min at 15m, 7 min at 12 m,

10 min at 9 m, 6 m for the remaining time

Test parameter: 40l/min air, 1.6l/min CO2,

4°C water temperature

Used diluent: 40 m - Air

100 m - Trimix 11/65

Soda lime The only supported soda lime is: Sofnolime® 797 manufactured by Molecular

Products.

Oxygen Cylinder 3 Liter steel cylinder (200 bar)

Diluent Cylinder 3 Liter steel cylinder (200 bar)

On board gas duration

Oxygen: The on board oxygen supply will last 252 minutes, if the diver consumes

1.78 liter of oxygen per minute.

3 liter x 200 bar = 600 liter - 25% reserve = 450 liter

Diluent: The duration depends on the depth and activity of the diver.

3 liter x 200 bar = 600 liter

Batteries

2 x 3.6v lithium (SAFT 14500). One battery for the

controller and one battery for the HUD.

2 x 9v block lithium

(Parallel operation for the solenoid)

Volume of the counter lungs 8 litres

Maximum application depth

Max. 40 m with air as diluent

Max. 100 m with trimix as diluent

Warning:

Dives exceeding a depth of 100 m are associated with numerous additional risks

Purity of the gases

Air: DIN EN 12021

Oxygen: >99.5% (medicinal oxygen)

Helium: >99.996

Atmospheric pressure range 800 – 1050mbar