6052931-UAI-A-0121

2 Johnson Controls Ducted Systems

Models

Nomenclature - electrical

Electric heat kit installation for air handlers:

AP, AE, AVC, AVV, MP, ME, MVC, AHR, AHE,

AHV, RFCX*E, and RFCX*P

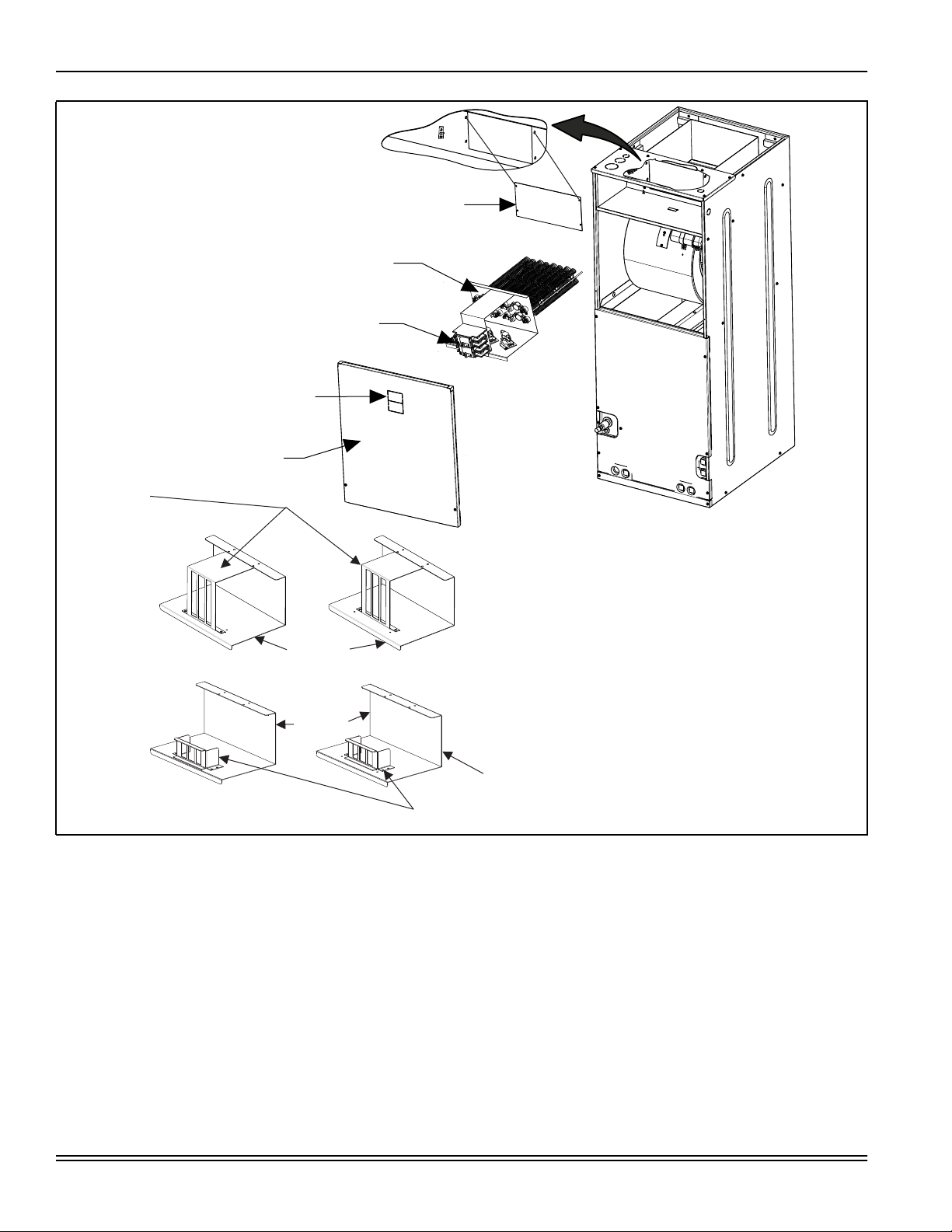

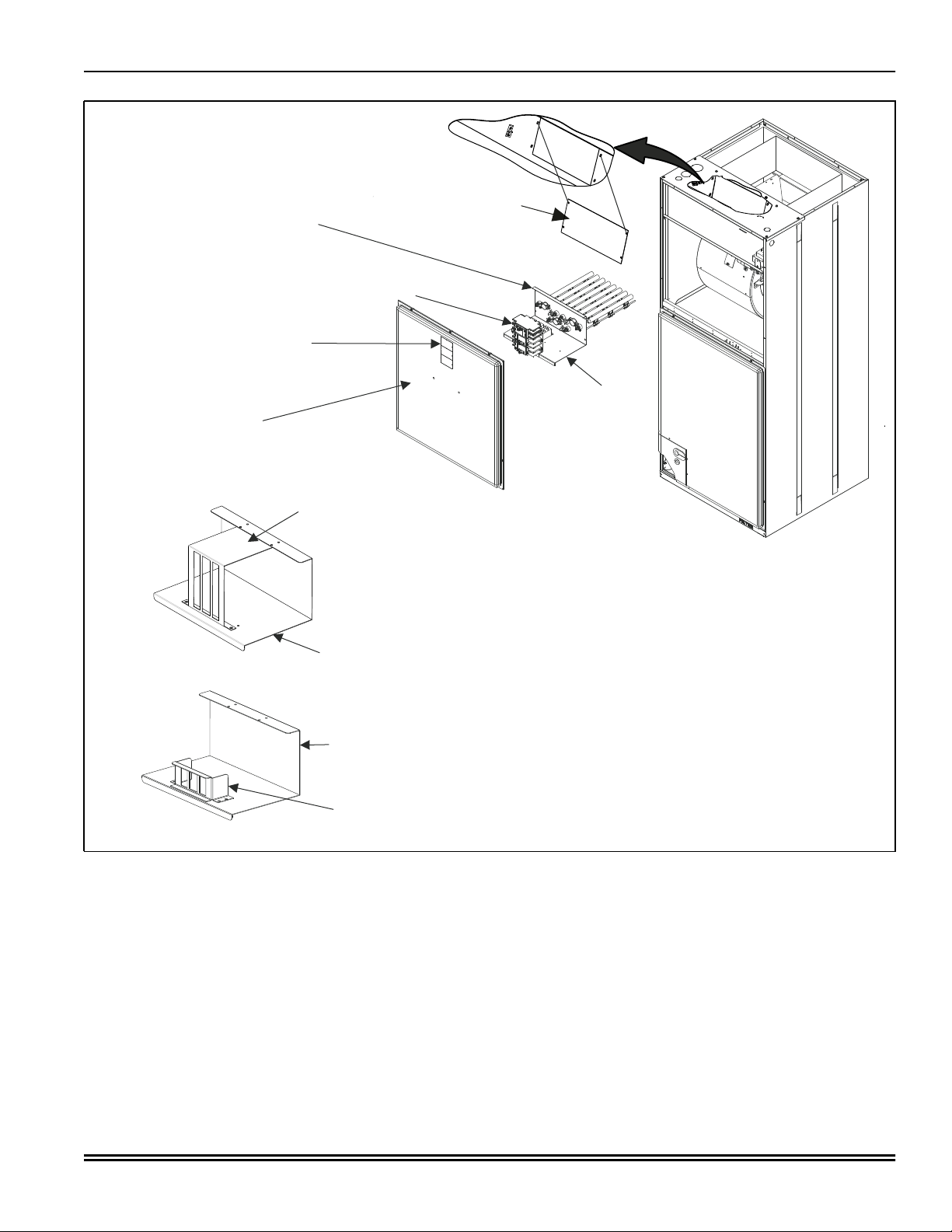

Installation is the same for all air handler operating positions:

upflow, downflow, and horizontal right or horizontal left. Install

the electric heat kit before unit installation. See Figure 3 or Fig-

ure 4 for a depiction of the components.

1. Ensure that there is no electrical power going to the unit.

2. Remove the air handler blower access panel.

3. If installing the electric heat kit in an AP, AE, AVC, AVV, MP,

ME, MVC, RFCX*E2, or RFCX*P2 model, leave the ser-

vice disconnect bracket in position A as shown in Figure 4.

Or

If installing the electric heat kit in an AHR, AHE, AHV,

RFCX*E1, or RFCX*P1 model, move the service discon-

nect bracket to position B as shown in Figure 3.

4. If the electric heat kit does not have service disconnects,

go to Step 5.

Or

If the electric heat kit has service disconnects, complete

the following before Step 5:

a. Examine the electric heat kit and take note of the num-

ber of service disconnects it has. Remove the appro-

priate number of service disconnect knockouts from

the front access panel of the air handler unit.

b. Cut the blower access panel insulation behind the ser-

vice disconnect plate and remove to open the area for

the service disconnects to protrude through the front

access panel and provide clearance for the service

disconnects and single-point wiring entry kit.

c. Add replacement non-foil faced insulation for the

exposed front panel if needed. Add rubber gasket to

the inside of the door for sealing.

5. Remove and recycle the duct cover from the back panel of

the air handler control and wiring compartment.

Table 1: Models covered

Electric

heat kit kW

at 240V

1 phase electric

heat kit1,2

(all except PHE)

1 phase electric

heat kit1,2,3

(PHE)

3 phase 208 V/230 V

electric heat kits

(PHE, PCE, AHR,

AHE, AHV, RFCX*E1,

RFCX*P1)

3 Phase 208 V/230 V

electric heat kits

(AP, AE, AVC, AVV,

RFCX*E2, RFCX*P2,

MP, ME, MVC)

3 phase 460 V

electric heat kits4

2.4 6HK(0,1)6500206 6HK(0,1)6500206 -- -- --

4.8 6HK(0,1)6500506 6HK(0,1)6500506 -- -- --

7.7 6HK(0,1)6500806 6HK(0,1)6500806 -- -- --

9.6 6HK(0,1)6501006 6HK(0,1)6501006 6HK06501025 6HK36501025 6HK06501046

12.5 6HK(1,2)6501306 6HK(1,2)6501306 -- -- --

14.4 6HK(1,2)6501506 6HK(1,2)6501506 6HK06501525 6HK36501525 6HK06501546

17.3 6HK(1,2)6501806 6HK(1,2)6501806 6HK06501825 6HK36501825 6HK06501846

19.2 6HK(1,2)6502006 6HK(1,2)6502006 6HK16502025 6HK46502025 6HK06502046

24.0 6HK(1,2)6502506 6HK(5,6)6502506 6HK16502525 6HK46502525 6HK06502546

1. (0,1) - 0 = no service disconnect or 1 = with service disconnect.

2. (1,2) - 1 = with service disconnect, no breaker jumper bar or 2 = with service disconnect and breaker jumper bar.

3. (5,6) - 5 = with service disconnect, no breaker jumper bar or 6 = with service disconnect and breaker jumper bar.

4. Use revision D or later for MP 460-V models.

6 Product category 6 = electric heat for AP, AE, AVC, AVV, MP, ME, MVC, AHR, AHE, AHV, RFCX*E, and RFCX*P residen-

tial air handlers and PHE and PCE residential packaged units

HK Family identifier HK = electric heat kit

1 Power connection

0 or 3 = terminal block

1, 4, or 5 = service disconnect

2 or 6 = service disconnect and single-point wiring kit

65 Class identifier 65 = electric heat kit

002 Electric heat, Nom. kW 002 = 2.5 kW, 005 = 5 kW, 008 = 8 kW, 010 = 10 kW, 013 = 13 kW, 015 = 15kW, 018 = 18 kW,

020 = 20 kW, 025 = 25 kW

25 Voltage code 06 = 208/230-1-60, 25 = 208/230-3-60, 46 = 460-3-60

C Style letter C = indicates sequential change of component style

D Style letter D = changed limit control cut out specification

CAUTION

Be aware that some units may have multiple power sources.

!