JOHNSON CONTROLS

8

FORM 145.05-SU7

ISSUE DATE: 10/31/2019

SECTION 1 - USER INTERFACE

Once a password is accepted, re-entry of that pass-

word is not required until key activity is idle for fifteen

minutes. This ensures that the menu system reverts to

password protection within an acceptable timeout.

NAVIGATION

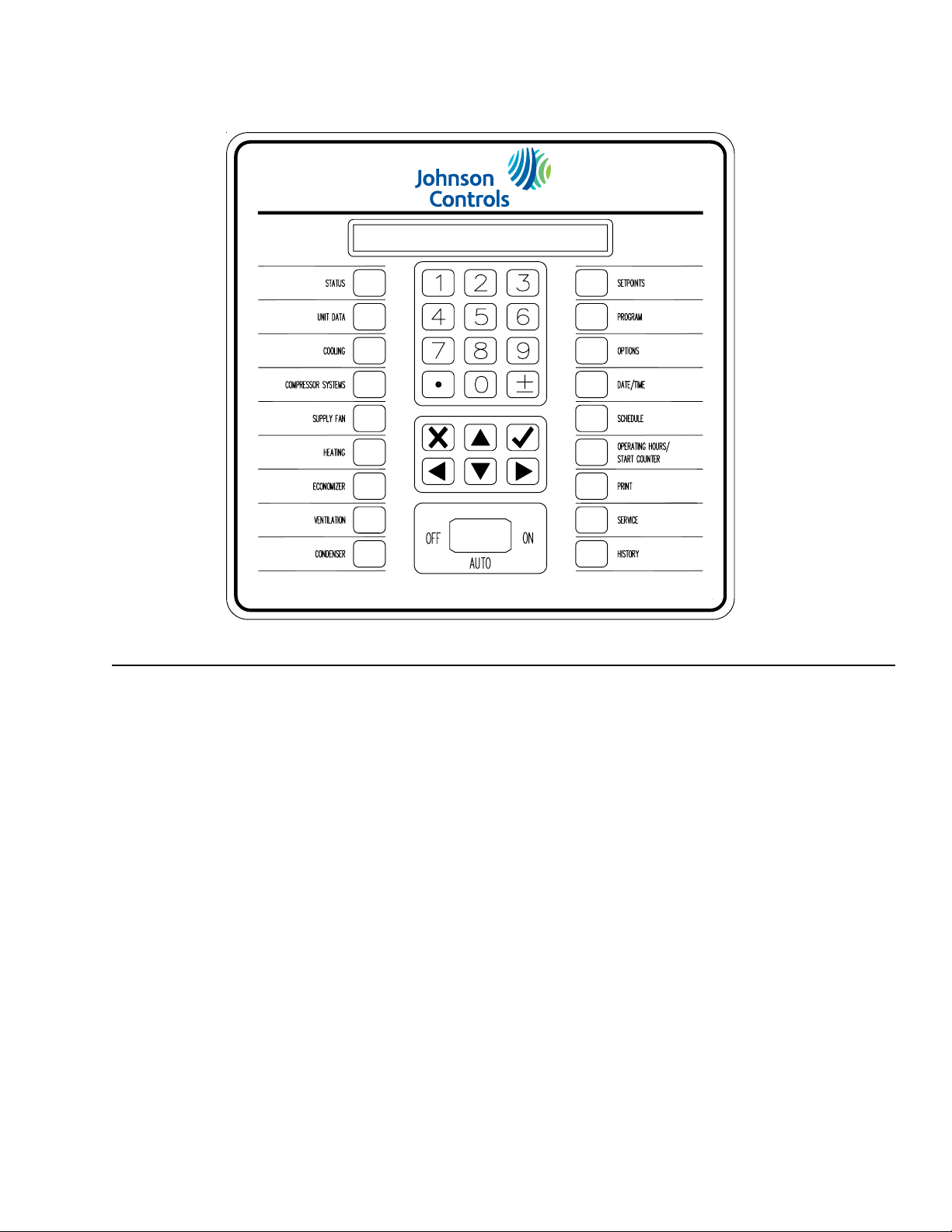

The keypad allows complete control of the system

from a central location. The keypad offers a multitude

of commands available to access displays, program pa-

rameters, and initiate system commands. The keypad

consists of thirty-six keys, which are divided into three

categories, Data Entry, Navigation, and Menu Selec-

tion keys. Each key is described in the sections below.

Data Entry Keys

Use the Data Entry Keys to enter values for items that

support edits. The keys available to support numeric

input are the 0 through 9 keys, the decimal key, the

+/- key, the key and the key. The keys available

to support choice input are the key, the key, the

key, and the key. Once editing has started, the

user must press either the key or the key. Any

other key press results in the “Press or to Exit”

message displayed for two seconds. If you try to edit

an item that is view only, it is ignored by the menu

system.

When a numeric value that can be modified is dis-

played under the “Setpoints” menu key, the Default,

High, and Low prompt is shown in the upper right por-

tion of the display. Pressing the +/- key, the decimal

key, or any of the 0 through 9 keys activate the edit

mode and a request for the proper password is made.

After the proper password is entered, the cursor is

shown at the digit to be changed. After the desired nu-

meric value is entered, press the key to save the new

value and exit the edit mode. Pressing the key fill

in the default value. Edits are only accepted when fol-

lowed by pressing the key. Pressing the key while

in the edit mode cancels the edit mode and leave the

value unchanged. If an out of range value is entered,

the Default, High and Low prompt is replaced by the

“Out of Range” message for two seconds.

When a choice value that can be modified is displayed

under the “Program” or “Options” menu key, the

prompt is shown to the left of the present choice.

The key or the key allow the different choices to

be viewed, and pressing either one activates the edit

mode and a request for the proper password made. See

Password section of this manual for the proper pro-

cedure for entering the password. When the desired

choice is displayed, press the key to save the new

value and exit the edit mode. Pressing the key while

in the edit mode cancels the edit mode and the value

is unchanged.

Navigation Keys

Use the Navigation Keys to browse items within a

menu. The keys currently available to support naviga-

tion are the Menu Select keys, the key, the key,

the key, and the key.

Menu Selection Keys

Pressing a Menu Select key brings the user to the first

screen under that menu. The screens within each menu

are arranged in a circular list. The user may browse

through the screens using the key and the key.

Pressing the key advances through the screens in

order from top to bottom until the bottom screen is

reached. When the bottom screen is displayed, press-

ing the key wraps the display to the top screen

of the menu. Pressing the key moves through the

screens in order from bottom to top until the top screen

is reached. When the top screen is displayed, press-

ing the key wraps the display to the bottom screen

of the menu. Once either the key or the key is

pressed, pressing any Menu Select key brings the user

to the first screen under that menu (even if it is the

same menu being viewed).

Navigation through the circular list of items is also

achieved by repeated presses of the same Menu Select

key, as long as no other keys are pressed. For exam-

ple, pressing the UNIT DATA key three times brings

the user to the third screen of the UNIT DATA menu;

pressing the UNIT DATA key once, then pressing the

key, then pressing the UNIT DATA key again brings

the user to the first screen of the UNIT DATA menu.

The key and the key are used to scroll “side-

ways” between the same displays for each system. For

example, when viewing the Sys 1 Pressures under the

COMPRESSOR SYSTEMS key, pressing the key

scrolls “sideways” to the Sys 2 Pressures display and

pressing the key scrolls “sideways” to the Sys Pres-

sures display for the last system on the unit.

When programming numeric or non-numeric values,

the key and the key are used to scroll forward

(down) and backward (up) through the items to be pro-

grammed or set.