4

Safety instructions

Due to their design and construction, TASKI machines comply with health and safety requirements of the EC guidelines

and therefore carry the CE sign.

This machine may only be used by persons who have been properly trained to do so.

In order to avoid unauthorised use of the machine, the machine must always be stored in an appropriate room.

Regularly test the elektonical mains cabel for cracks or aging.

Repairs to electrical components may only be carried out by authorised TASKI customer service workshops or experts who

are experienced in all aspects of the relevant security and safety regulations.

Min. requirement for the power supply cord H05VV-F3G1.or H07RN-F3G1.0.

Attention, make sure that the power supply cord does not get touch the rotating brushes.

It is forbidden to plug in or unplug the main power supply with wet hands.

Please make sure that the voltage on the label coincides with the specified voltage.

While operating the machine, take note of the surrounding area and pay particular attention to third parties and children.

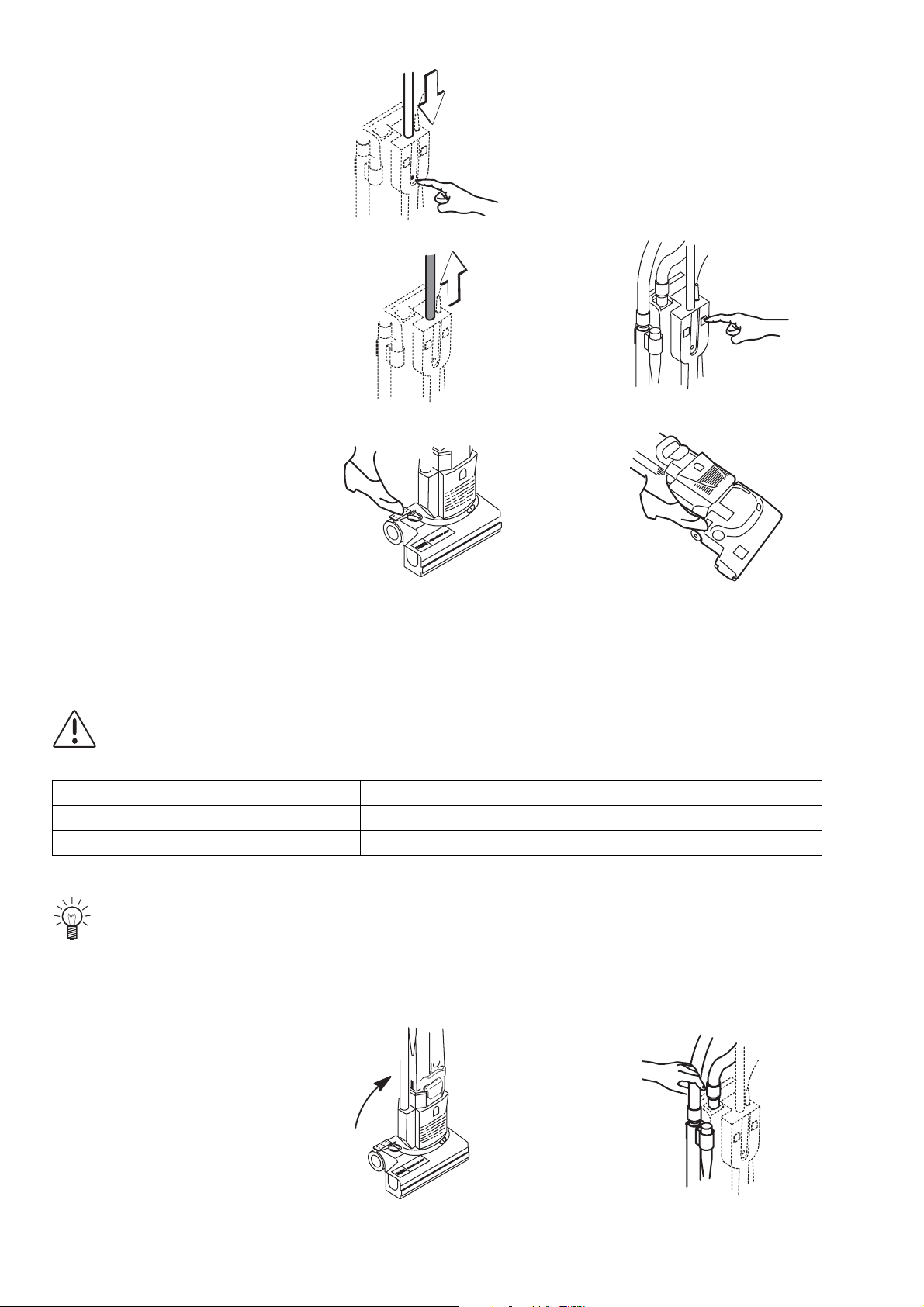

Only use tools (brushes, pad drives) which are mentioned in the instructions of use. Use only tools the TASKI-technical

specialist recommend (Page 16).

The use of other tools may impair the machine`s safety and or cause damage to machine.

Be sure not to damage the power supply cord by driving over it, crimping, tearing or damaging the power supply cord by

heat, oil or sharp edges.

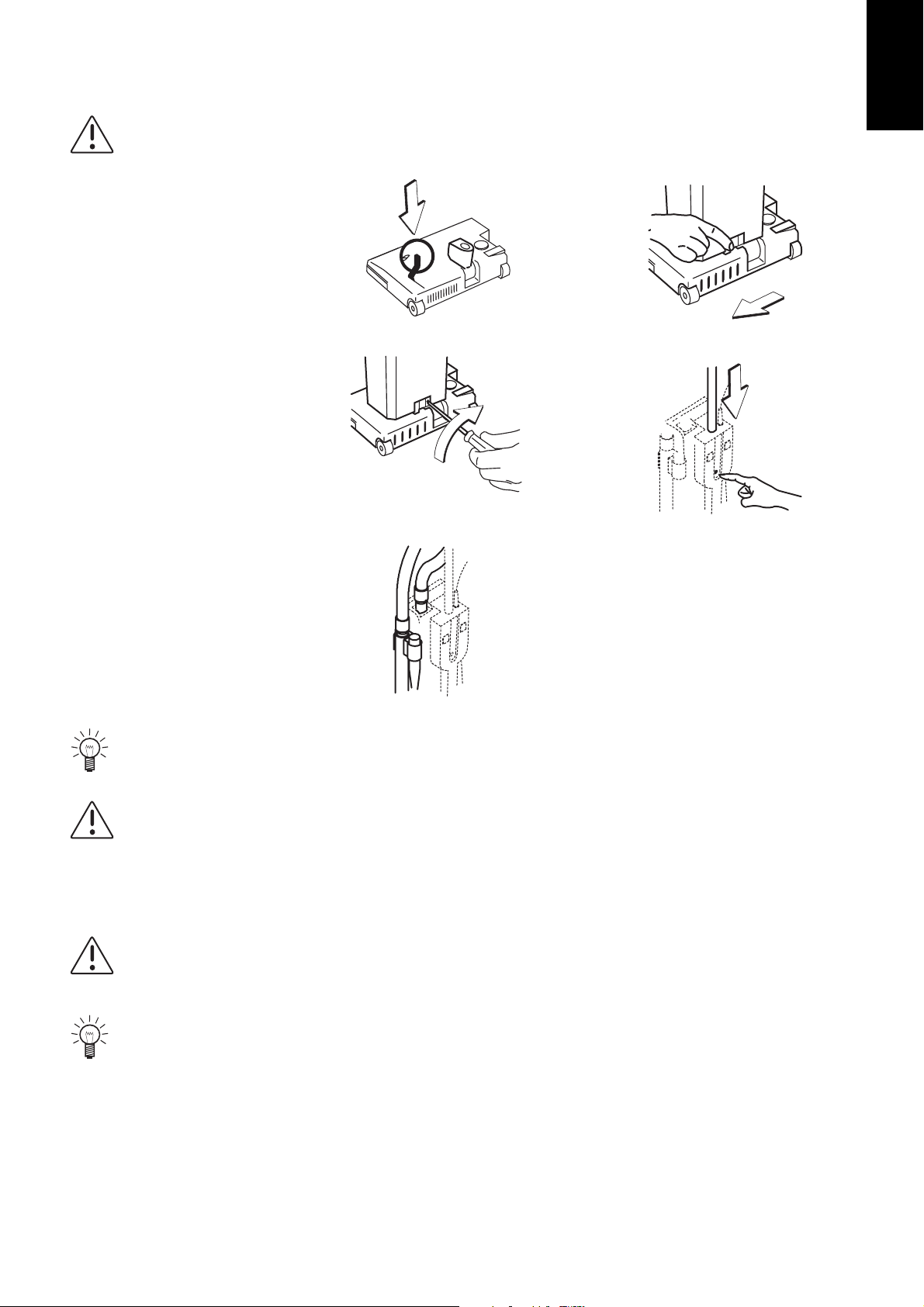

Turn off the machine before:

• cleaning it

• converting to another function (e.g. changing tool)

• carrying out maintenance

• replacing wear and tear parts

• leaving machine unattended

Do this by pulling the plug out of the socket.

Do not use the machine in rooms where explosive and flammable substances (e.g. petrol, paint thinners, heating oil,

solvents, etc.) are stored or processed.

The machine`s electrical parts or mechanical components could lead to the ignition of these substances.

Do not use this machine to vacuum toxic, poisonous, caustic or irritating substances (e.g. acids, alkalis, hazardous dusts,

etc.).

The filter system cannot retain such substances sufficiently. This might negatively affect the health of the user and third parties.

This machine is not suitable for outside use.

Store the machine in a dry, dust-free room with a corrosion-free atmosphere.

The temperature may not be below +10 °C, and not exceed +35 °C. Low temperatures, moisture and dust can strongly reduce

the life of rechargeable batteries and the electronics.

Caution:

Do not operate the machine if it is not in a faultless condition, and ensure its maintenance by expert personnel!