2

1. General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Technical Specications . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Transportation, installation and commissioning . . . . . . . . . . . . 6

3.1. Transportation method . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2. Storage method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3. Operating site requirements . . . . . . . . . . . . . . . . . . . . . . .6

3.4. Equipment installation and preparation for operation . . . . . . . . 6

3.5. Connection and commissioning . . . . . . . . . . . . . . . . . . . . 6

3.6. Operation of energy-saving night blinds (curtains) . . . . . . . . . . 8

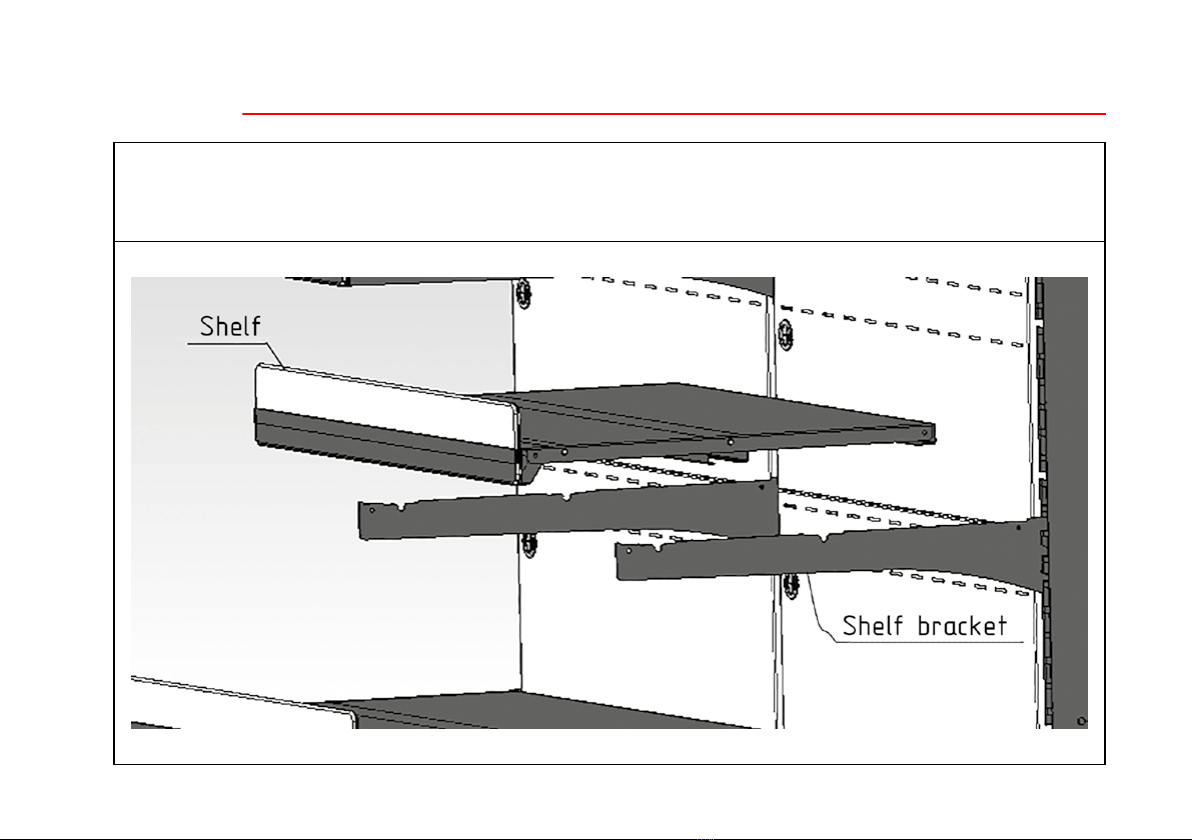

3.7. Assembling a line of refrigerated multideck ADX . . . . . . . . . . . 9

4. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1. Operating procedure of the CAREL electronic controller . . . . . 19

4.1.1. Light signals on the electronic controller display . . . . . . . . . 19

4.1.2. Temperature setting . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.3. Additional defrosting . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.4. Warning signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2. Operating procedure of the Dixell electronic controller . . . . . . 19

4.2.1. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.2.Checking the set temperature . . . . . . . . . . . . . . . . . . . . 20

4.2.3. Changing the temperature . . . . . . . . . . . . . . . . . . . . . . 20

4.2.4. Manual defrost request . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.5. List of alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5. Preservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1. Cleaning and preservation . . . . . . . . . . . . . . . . . . . . . . . 20

5.1.1. Cleaning the equipment . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.2. Defrosting the evaporator . . . . . . . . . . . . . . . . . . . . . . 21

5.1.3. Condenser maintenance . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.4. Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6. Identifying and correcting malfunctions . . . . . . . . . . . . . . . . 22

7. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

OPERATING INSTRUCTIONS FOR UPRIGHT REFRIGERATED CABINET (REGAL) ADX

Dear Customers! Read the manual of the upright refrigerated cabinet before you start using it,

which will ensure long and ecient operation of the equipment!

Table of contents