F250, F500, F1000

CONTENT

1. Intended use ................................................................................................................4

2. Operator responsibility – Safety recommendations .......................................................4

3. Handling.........................................................................................................................5

3.1. Appropriate operation............................................................................................5

3.2. Use........................................................................................................................5

3.3. Disposal ................................................................................................................6

4. Technical specifications.................................................................................................7

4.1. F250 ......................................................................................................................7

4.2. F500 ......................................................................................................................8

4.3. Warning functions and safety installations ..........................................................10

4.4. Materials of Construction of the wetted Parts......................................................11

5. Safety Notes ...........................................................................................................13

5.1. Description of the safety notes ............................................................................13

5.2. Explanation of other notes...................................................................................13

5.3. Safety instructions...............................................................................................14

6. Moving up and connect................................................................................................15

6.1. Transportation and site conditions.......................................................................15

6.2. Tubing .................................................................................................................16

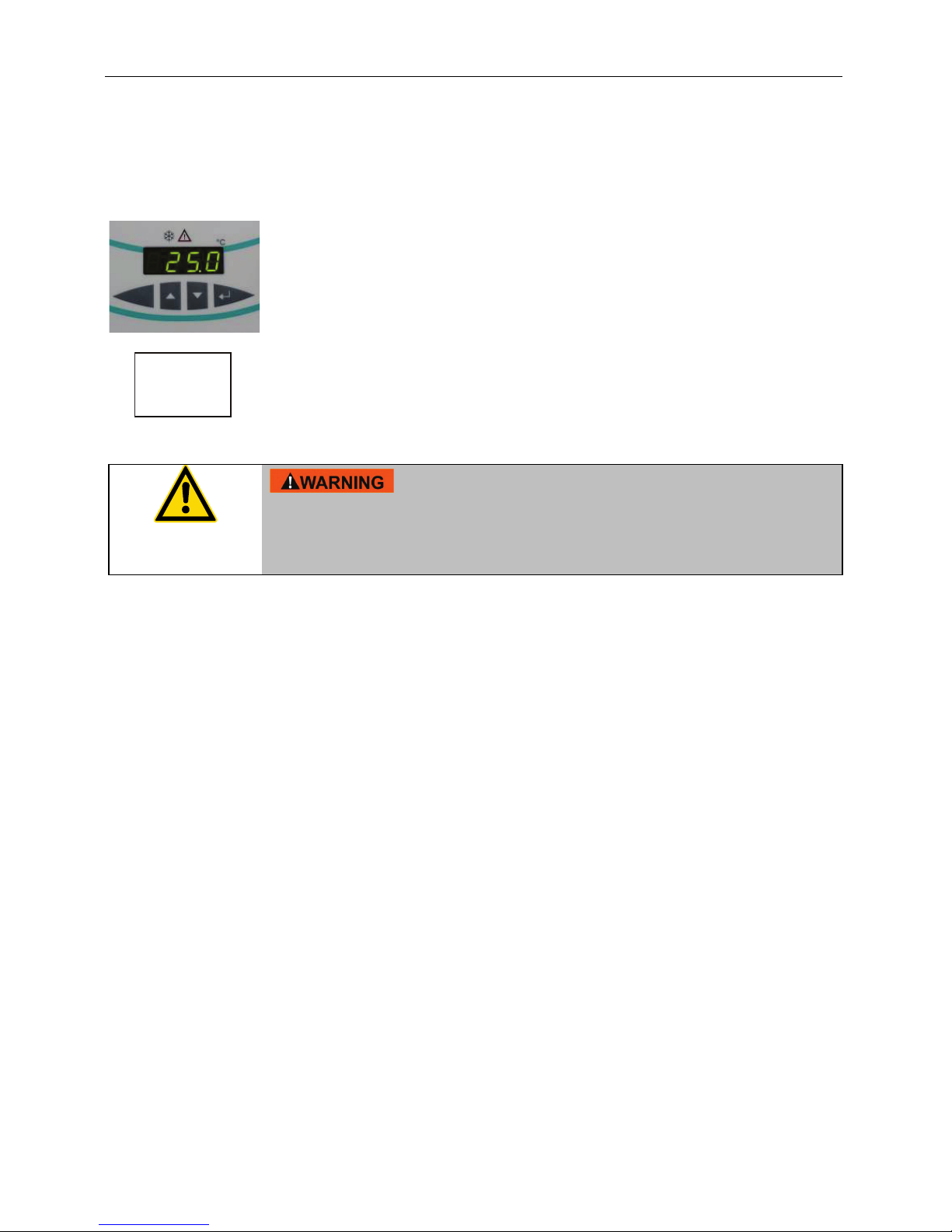

7. Operating controls and functional elements.................................................................18

7.1. F250 ....................................................................................................................18

7.2. F500 ....................................................................................................................20

8. Operating procedures ..................................................................................................22

8.1. Bath fluids ...........................................................................................................22

8.2. Power connection................................................................................................23

8.3. Filling...................................................................................................................23

8.4. Switching on / Start - Stop...................................................................................24

8.5. Setting the temperatures .....................................................................................24

8.6. Timer function......................................................................................................25

8.6.1. Setting the time ................................................................................................ 25

8.6.2. Timer operation ................................................................................................ 25

8.7. AUTOSTART ON / OFF ......................................................................................26

9. Safety installations.......................................................................................................27

9.1. Excess temperature protection............................................................................27

9.2. Low level protection.............................................................................................27

10. Troubleshooting guide / Error messages .....................................................................28

11. Cleaning / repairing the unit.........................................................................................30

11.1. Draining...............................................................................................................31

12. Warranty conditions .....................................................................................................32

12.1. EC-Declaration of Conformity..............................................................................33

1.951.4806-V2 3