5www.juwent.com.pl

1. INTENDED USE

UGW/D heating and ventilation units, size 10÷12, are intended to heat and ventilate such

compartment as:

»industrial halls

»warehouses

»workshops

»other objects of similar use

The units should be used only according to the intended use.

The manufacturer is not liable for using the units against the intended use and for any

damages arisen for this reason.

Heating and ventilation units cannot be used in the compartments with relative humidity

larger than 95% and air dust concentration over 5mg/m3.

The compartment can be served by one or larger number of the units, also by the units of different

sizes.

Units are suitable for mounting on walls at a height that allows direct air ow to the heated area.

Units are equipped with centrifugal fan allowing independent operation of the device or witch

attached additional equipment with air pressure drop up to 100 Pa.

The units can operate as heating units optionally with attached air lter at fan sucking side or as

heating and ventilation units with added intake boxes. The intake boxes enable to draw circulating

air, fresh air, or mixed in any proportion.

2. DESIGNATIONS

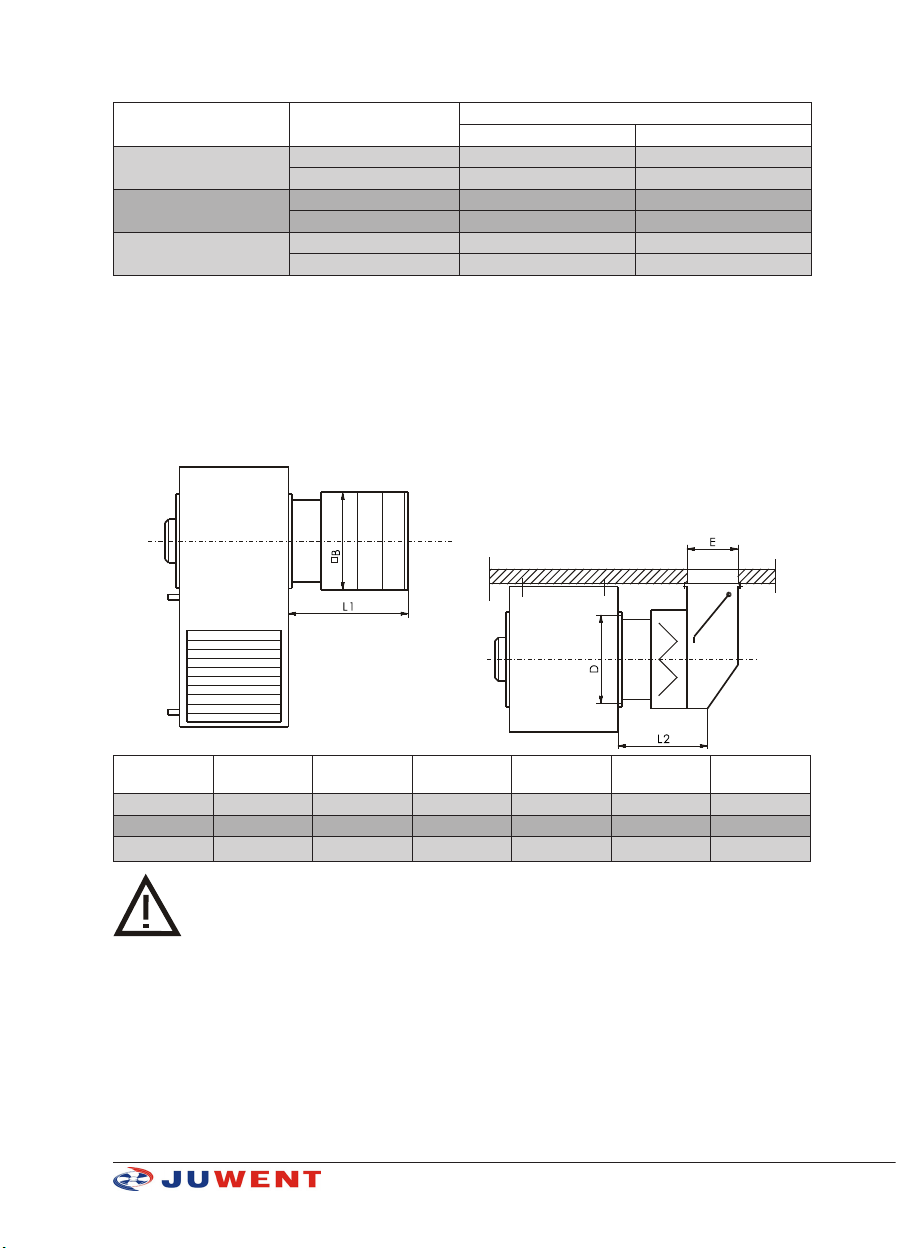

Heating and ventilation unit UGW/D- - - - - -

Size 10; 11; 12

Heating medium water (W); (oC);(MPa)

steam (P);(MPa)

Number of heating coil rows III, IV for water,

II, III for steam

Motor type

two speed three phase (TD);

single phase (J);

single speed three phase(T)

Speed 900/1400rpm, 1400rpm for size 10, 11

670 or 900 rpm for size 12

Type right (R) or left (L)

oC - heating medium temperature

MPa - permissible heating medium pressure

3. OPIS URZĄDZENIA

The unit consists of:

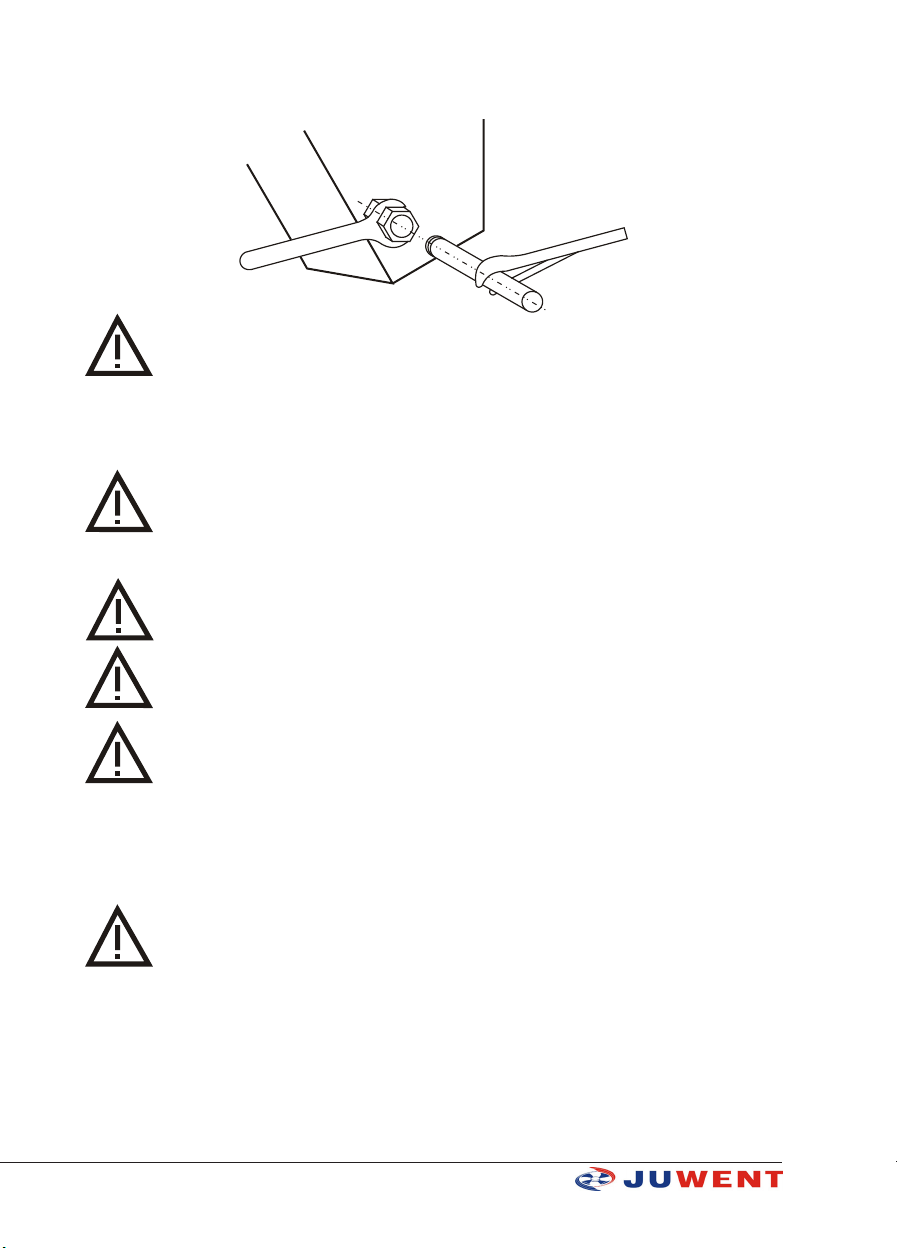

»highly efcient centrifugal fan in chemicals resistant version (1);

»water or steam heating coil (2);

All heating coils are made of bimetallic tubes i.e. steel core barrel and aluminium ribs rolled outside.

Standard water heating coils are made of tubes with the following dimensions: inner diameter

d=12,4mm, rib outer diameter D=38mm and ribs spacing 2,8mm and the steam heating coils are

made of tubes with d=21,4mm inner diameter, element outer diameter D=58mm and ribs spacing 5

mm. Connection spouts of the units with the steam and water heating coils are with threads.