10 www.juwent.com.pl

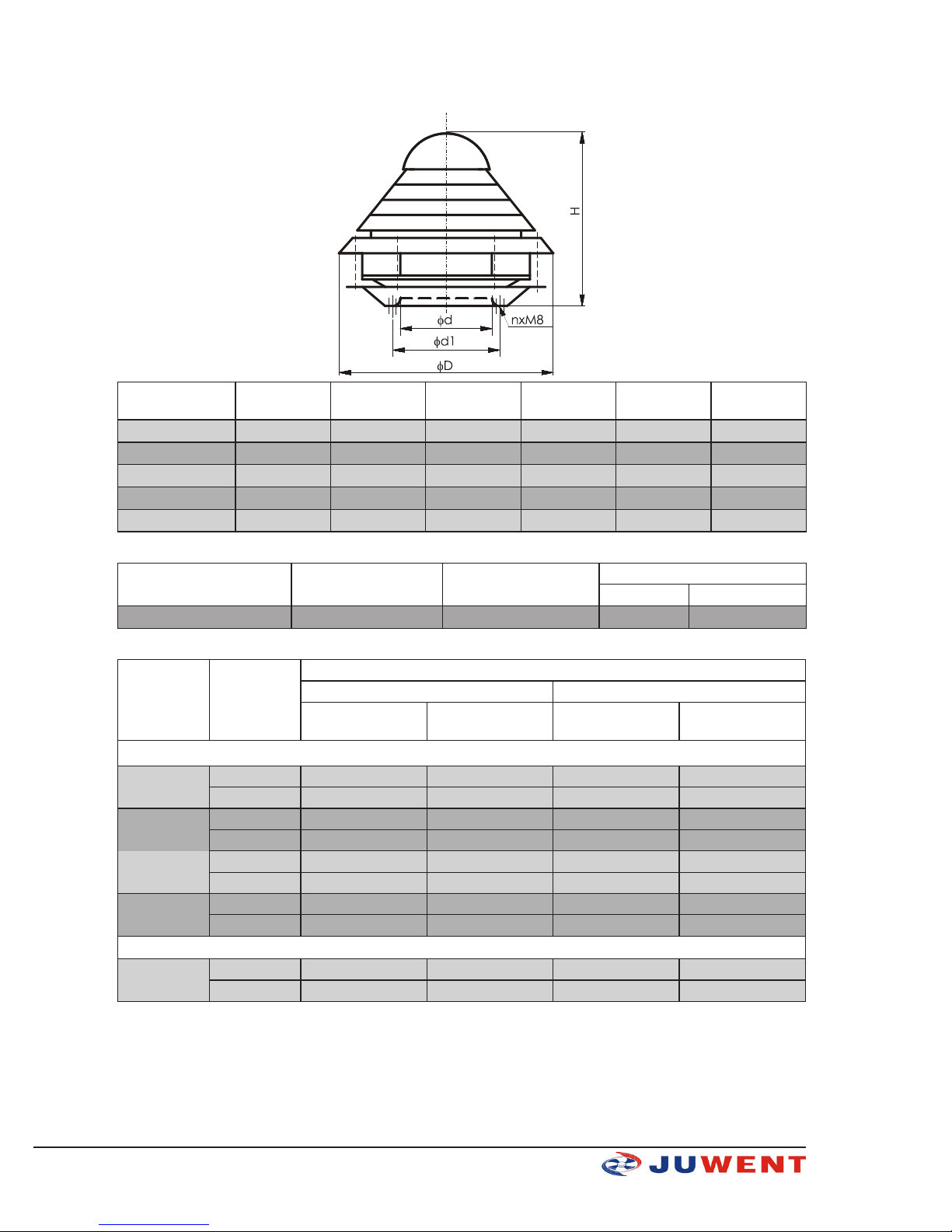

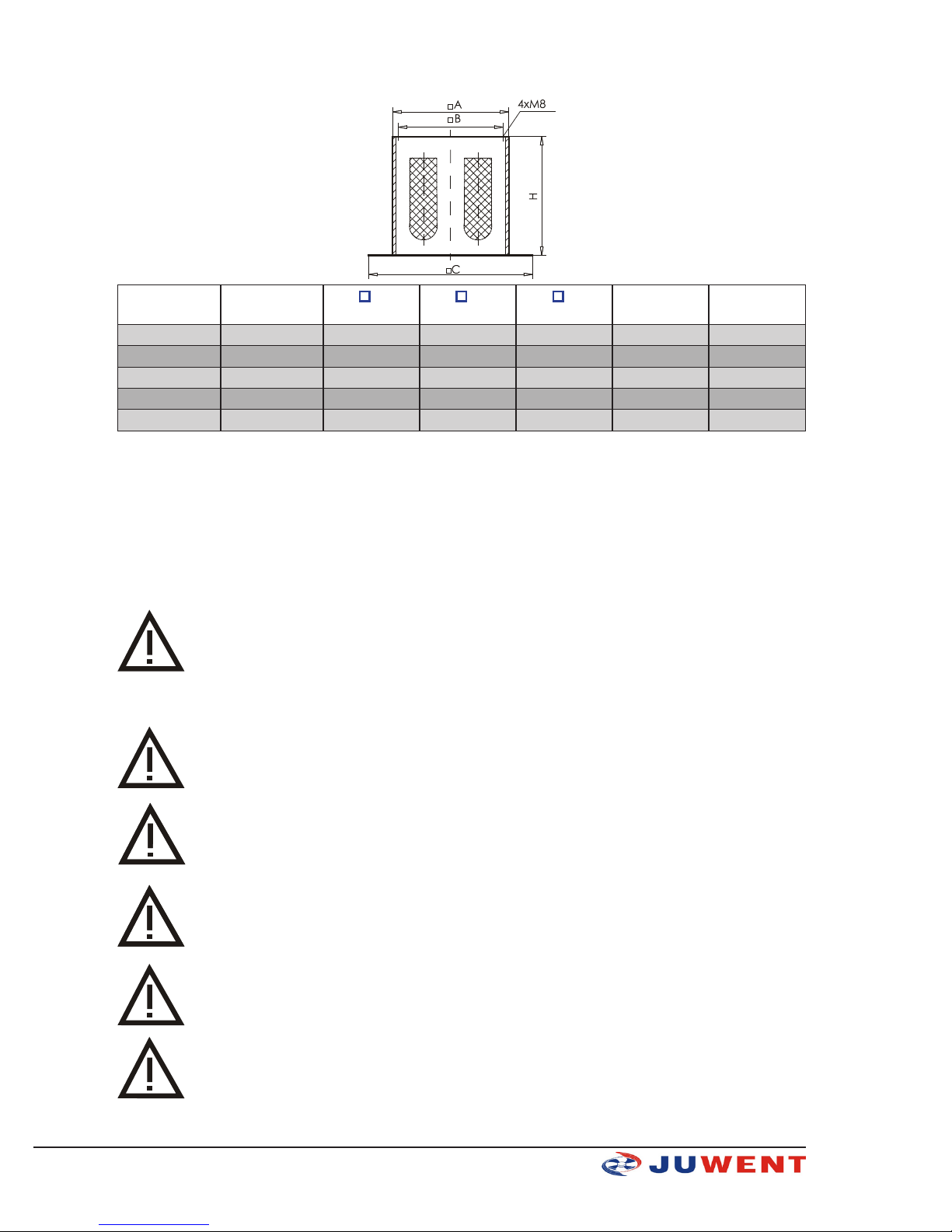

PUT noise damping roof base

Fan type Base size A

[mm]

B

[mm]

C

[mm]

H

[mm] Weight [kg]

WD-16 PUT-1 360 330 662 700 22,5

WD-20 PUT-2 412 380 712 700 25,5

WD-25 PUT-3 452 420 752 700 27,5

WD-31,5 PUT-4 512 480 812 700 30,5

WD-40 PUT-5 592 560 892 900 49

Efciency of universal base noise damping is in the A scale ~14dB(A).

7. TRANSPORT

Fans are delivered as completely assembled, protected against pollutions and weather with

polyethylene foil or cartboard box.

The fan is delivered with the Product Book.

The PU and PUT roof bases are additional equipment and are delivered separately protected with

polyethylene foil.

The fans should be transported on one level so as to prevent any mechanical damages.

8. SAFETY RECOMMENDATIONS

Roof fans should be used in accordance with the operation manual.

Installation, connection, commissioning, inspection and repair works on the fans should

be performed by an authorised technician, and electrical works by a person holding the

required qualications.

All maintenance and repair works should be carried out with voltage off

In the case of the fan failure immediately turn the motor electrical power supply off.

The fan can only work with properly operating electrical protection devices. It must be

uninterruptedly connected to the electrical installation tted with protection terminal,

residual-current device and service switch.

Use original spare parts only.