8 Service Manual MW 800.0

For internal use only

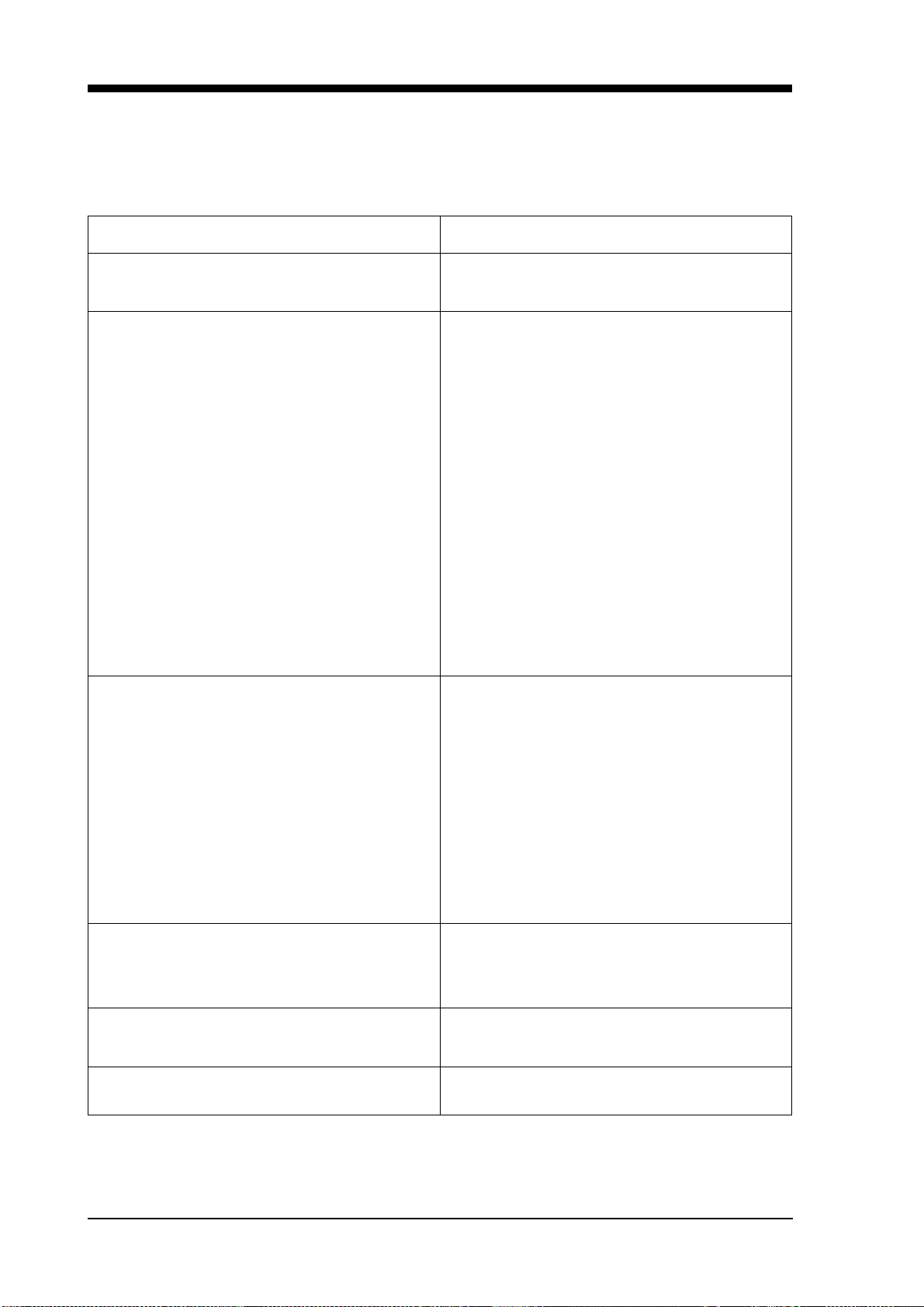

3. Trouble shooting guide

3.1 Trouble shooting table

Problem Points to check

Cavity lamp does not light, but other electrical

components (e.g. turntable) are working. 1. Lamp burnt.

2. Bad contact between lamp and lamp socket.

Cavity lamp does not light, all other electrical

components also do not work. 1. Power outlet has no contact to the socket.

No electric supply.

2. Fuse blown.

3. Faulty contact between fuse and fuse

holder/clip.

4. Loose door hinge, door not set properly,

adjustment of locking not correct; this leads

to blowing of the fuse.

5. Faulty connection UL-switch.

6. Short-circuit in electric circuit. Filament of

lamp blown, short-circuit of high-voltage

capacitor; this leads to blowing of fuse.

7. Faulty contact of contacts or connectors of

control element, or primary or secundary

interlock switch.

8. Defective high-voltage diode .

The microwave seems to function but the food

stays cold. 1. Defective magnetron (defective thread,

thread short-circuited to earth, etc).

2. Earth conductor of high-voltage transformer

defective.

3. Filament short-circuited to earth.

4. Damaged filament.

5. Faulty contact at magnetron connectors.

6. Defective control units.

7. Damaged high-voltage diode, a humming

sound occurs.

Microwave runs for a short period of time, but then

stops. 1. Blocked cooling fan.

2. Open cooling fan motor circuit.

3. Defective cooling fan control relay.

Turntable does not turn. 1. Defective turntable motor.

2. Deformed turntable shaft.

Circuit breaker is activated. 1. Strong leakage of electrical components

(mostly motor).