MANUAL LEVER PUMP

INSTRUCTIONS AND PRECAUTIONS

PLEASE SAVE THESE INSTRUCTIONS.

READ ALL PRECAUTIONS AND INSTRUCTIONS CAREFULLY.

SPECIFICATIONS

Item / Model Manual Lever Pump / 40174

Delivery Volume About 500cc per Stroke

Applicable

Liquids

AdBlue®, Water, Lubricants,

Windshield Washer Fluid,

Antifreeze, Mild detergents,

Agricultural chemicals etc.

Applicable range

of Temperature About -5°C ~ +45°C

Main Materials Polypropylene, Polyethylene, Viton /FKM

OPERATING INSTRUCTIONS

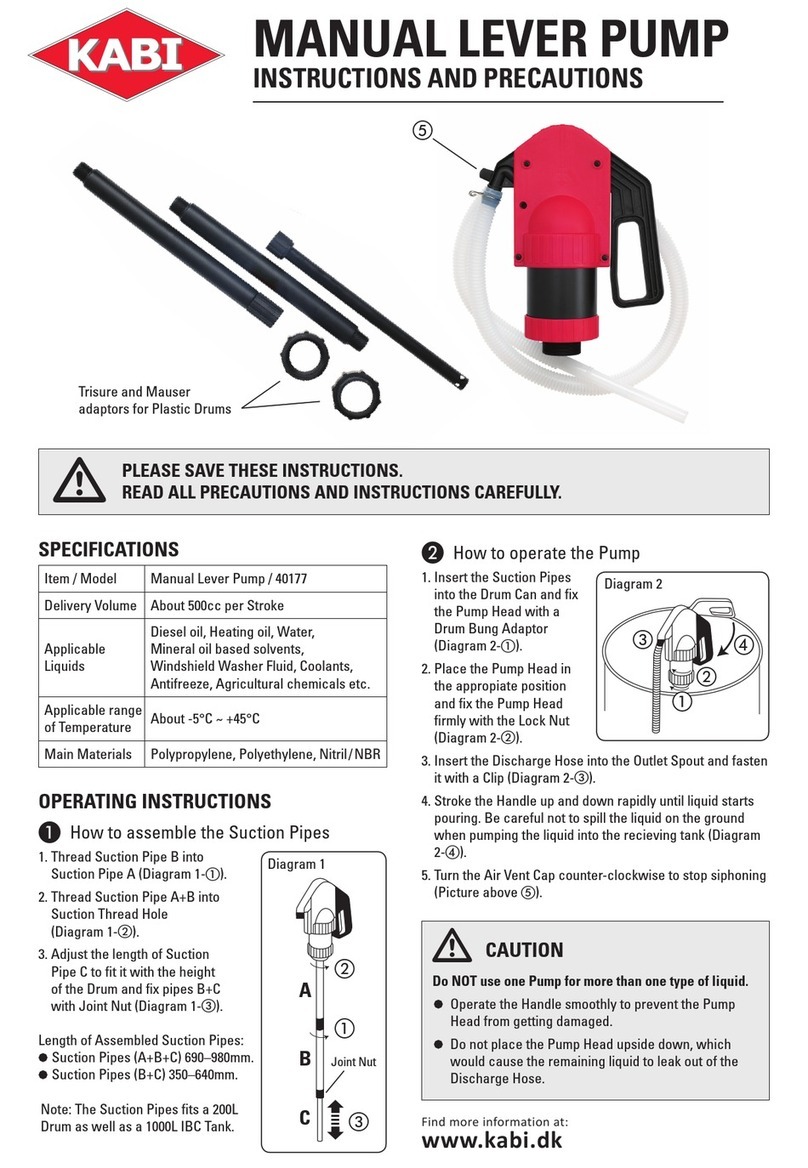

How to assemble the Suction Pipes

1. Thread Suction Pipe B into

Suction Pipe A (Diagram 1-).

2. Thread Suction Pipe A+B into

Suction Thread Hole

(Diagram 1-).

3. Adjust the length of Suction

Pipe C to t it with the height

of the Drum and x pipes B+C

with Joint Nut (Diagram 1-).

Length of Assembled Suction Pipes:

• Suction Pipes (A+B+C) 690–980mm.

• Suction Pipes (B+C) 350–640mm.

Note: The Suction Pipes ts a 200L

Drum as well as a 1000L IBC Tank.

How to operate the Pump

1. Insert the Suction Pipes

into the Drum Can and x

the Pump Head with a

Drum Bung Adaptor

(Diagram 2-).

2. Place the Pump Head in

the appropiate position

and x the Pump Head

rmly with the Lock Nut

(Diagram 2-).

3. Stroke the Handle up and down rapidly until liquid starts

pouring. Be careful not to spill the liquid on the ground

when pumping the liquid into the recieving tank (Diagram

2-).

4. Turn the Air Vent Cap counter-clockwise to stop siphoning

(Picture above ).

CAUTION

Do NOT use one Pump for more than one type of liquid.

• Operate the Handle smoothly to prevent the Pump

Head from getting damaged.

• Do not place the Pump Head upside down, which

would cause the remaining liquid to leak out of the

Discharge Hose.

Diagram 2

Diagram 1

Joint Nut

A

B

C

Find more information at:

www.kabi.dk

Trisure and Mauser

adaptors for Plastic Drums