2. DESCRIPTION OF FUNCTION

5

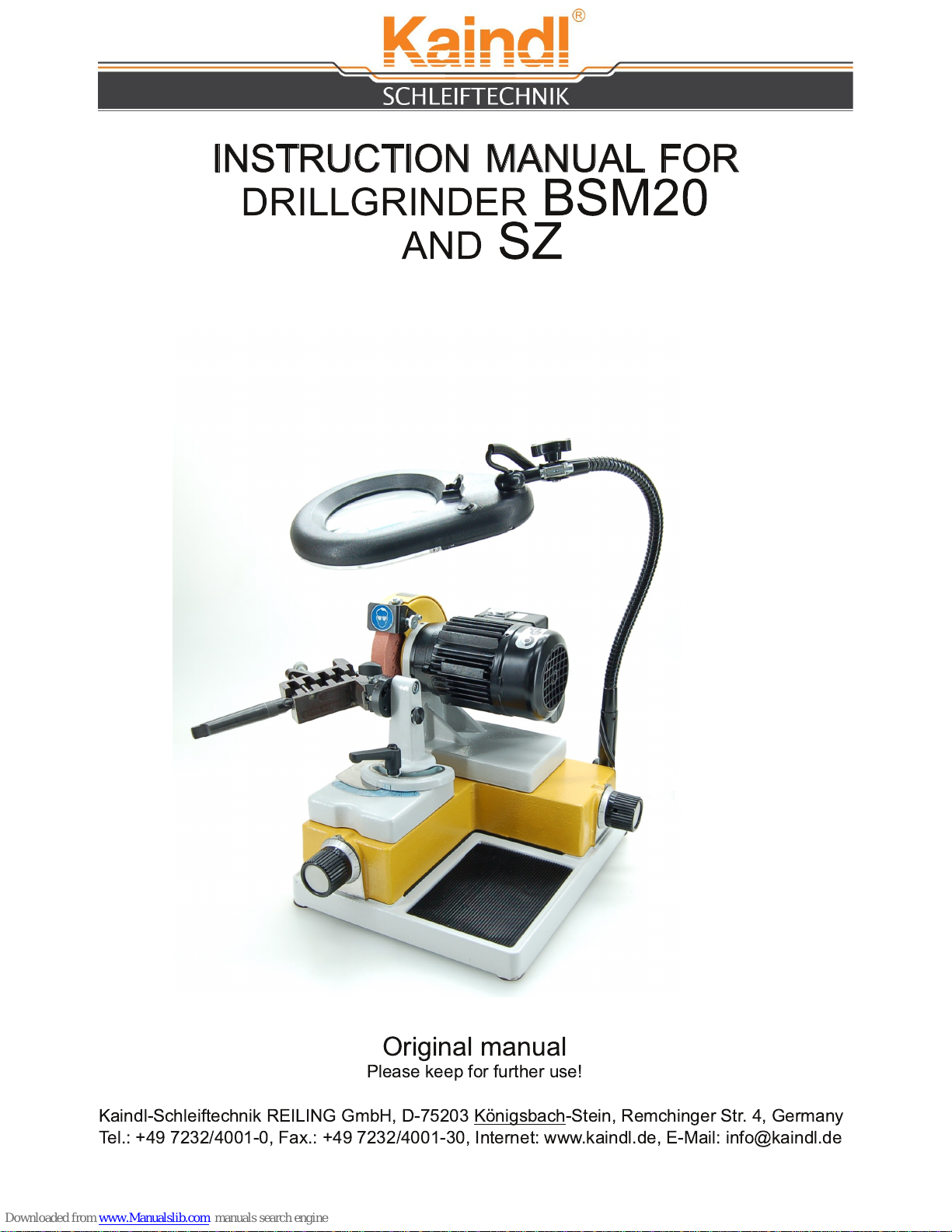

This mobile drill grinding machine made by Kaindl is unique as to its design and offers a

genuine alternative to bigger and considerably more costly equipments. Owing its solid

construction, its high precission, its small space requirement and its favourable price, the Kaindl

grinding machine is an indispensable auxillary equipment and a real measure of economy even

for single operation sections and for smaller workshops. The machine facilitates the adjustment

and the resharpening of twist drills to that extend, that everybody will be able to resharpen drills

with every lib angle that is imaginable. Form the prism reversing process results automatically

the highest precision and cutting egde symmetry. The well planned conception and the

possibility of an easy change of all party subject to wear, preserve the Kaindl drill grinding

machine as an indespensable aid in your work-shop. Even after many years of employment.

BSM 20: Range 1 - 20 mm (prism), complete with CBN-grinding wheel and optical lens

LED lighted.

SZ: with corundum cup wheel and grinding table with electro magnet, diamond cup wheel,

diamond dresser and optical lens LED lighted.

1 7073 CBN grinding wheel ø 1 25 mm grit B1 26/3, covered on 3 sides, broad 20 mm

1 6490 CBN grinding wheel ø 1 25 mm grit B76/3, covered on 3 sides, broad 20 mm (standard)

1 7556 CBN grinding wheel ø 1 25 mm grit B46/3, covered on 3 sides, broad 20 mm

1 0895 Corundum grinding wheel 1 25 x 20 x 20 grit 60 (coarse)

1 0890 Corundum grinding wheel 1 25 x 20 x 20 grit 80 (standard)

1 0891 Corundum grinding wheel 1 25 x 20 x 20 grit 1 80 (very fine)

1 0893 Corundum grinding wheel 1 25 x 05 x 20 grit 1 00 (HSS wood bits)

1 0896 Corundum cup wheel grit 60 (standard) for SZ

1 0897 Corundum cup wheel grit 80 (medium) for SZ

1 0898 Corundum cup wheel grit 1 00 (fine) for SZ

1 5422 rinding wheel support

1 4581 Diamond grinding wheel D 76, covered on 3 sides for carbide wood drills

1 4580 Diamond grinding wheel D 76, covered on 3 sides for carbide drills

11 223 Diamond cup wheel D 1 26 (standard) for SZ

1 0887 Diamond cup wheel D 76 (fine) for SZ

1 0906 Universal clamping device for single-lip cutters, cut off tools, etc. for SZ

1 0889 Magnetic depth stop for cutters

1 0875 Countersink sharpening device SVR 20 with collet 1 0 mm

1 0877 Collet 6 mm for SVR 20

1 0878 Collet 8 mm for SVR 20

1 0879 Collet 1 2 mm for SVR 20

1 0901 Morse taper sleeve MK1

1 0902 Morse taper sleeve MK2

2.1 BASIC EQUIPMENT BSM 20 / SZ

3. ACCESSORY AND SPARE PARTS BSM 20 / SZ