1. Introduction to the Manual 2. General Precautions

The purpose of this manual is to provide the

necessary information for competent, safe use of

the equipment.

This information is the result of continuous,

systematic data processing and technical tests

recorded and validated by the manufacturer, in

accordance with the internal procedures to

ensure the safety and quality of information: EN

89/392, EN 60204-1, CEI 110-8, IEC 801, EN

202-2, EN 418, prEN 1050, prEN 614-1.

The information below is intended

EXCLUSIVELY for specialized users, capable

of interacting with the product with the utmost

safety for people, the machine and the

environment, interpreting basic diagnostics of

problems and malfunctions and performing

simple checks and maintenance, in full

compliance with the instructions given in the

pages that follow and with current health and

safety regulations.

The document does not examine in depth the

topics of disassembly and extraordinary

maintenance, as these operations must always be

carried out solely by our authorized Technical

Service.

For a proper relationship with the product, it is

essential to ensure that the manual remains

legible and well-preserved, for future reference.

Should it deteriorate or, more simply, for further

technical and operating information, contact the

nearest Authorized Retailer directly.

Before using the machine or opening its

packaging, read the instructions in the following

manual very carefully.

If the machine is used by more than one

operator , each one must adhere to the following

manual very carefully.

The Manufacturer declines any responsibility

for damage to persons, things or to the machine

itself arising from its incorrect use, negligence

and superficial interpretations of safety concepts

contained in this manual.

This instructions manual should serve the

duration of the machines operating “life” and be

available for at least 10 (ten) years: it is

advisable to keep it in a known and accessible

place (possibly together with the other manuals

relating to the machine).

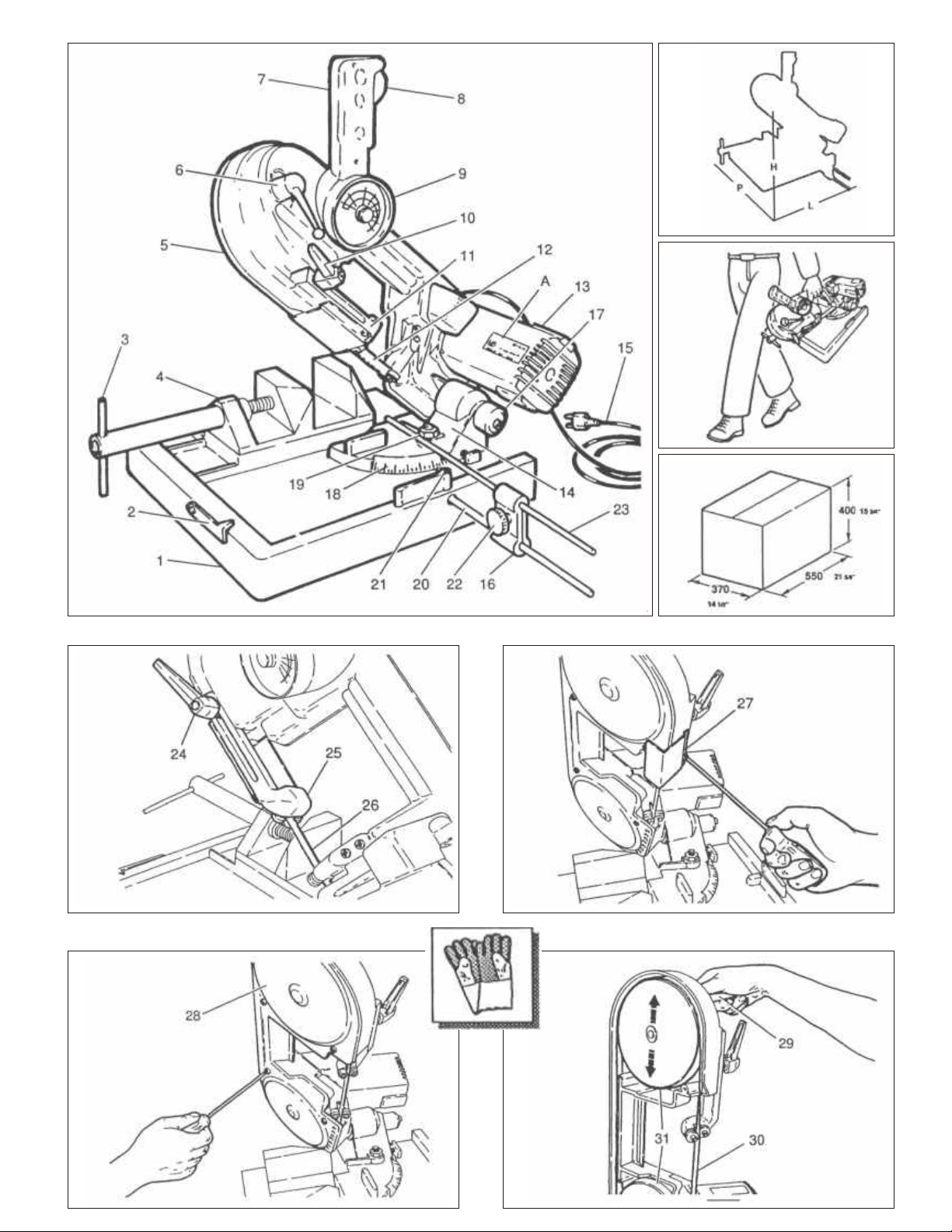

Always make sure in advance that the minimum

safety, placement and operating standards are

respected, taking note of the environmental

conditions, temperature, humidity, lighting,

vibrations, suspended dust and the appropriateness

of the area to be occupied.

The saw may operate outdoors (work sites, open

spaces in general, etc.) or indoors (workshops,

laboratories, etc.) where there is no risk of

explosion or fire.

Before using the equipment, make sure that the

surface where the machine will be placed is flat,

sufficiently sturdy and ergonomical: we recommend

using a workbench for this reason.

Always make sure in advance that the workpiece is

tightly clamped; in any case, make sure that the

start of the production cycle does not create

hazardous situations for people and/or property.

Do not remove or damage the information plates on

the machine; you must recognize their meaning and

keep the message legible. Should they deteriorate,

replace immediately, contacting only an authorized

Technical Service directly.

The use of spares that do not respond to the

specifications listed below, changes or tampering -

however slight- shall exempt the manufacturer from

any responsibility regarding the proper use,

functioning and safety of people and/or property.

It is strictly forbidden to tamper with safety

equipment and/or devices.

Dispose of processing waste in compliance with

current regulations.

Any maintenance operation except for

those specifically described in the pages

of this manual, must be carried out by

skilled personnel co-ordinated directly

by the authorized Technical Service.