P 1/ 45

CONTENTS

[1] NECESSARY REPAIRING TOOLS .........................................................................2

[2] LUBRICATION.................................................................................................................2

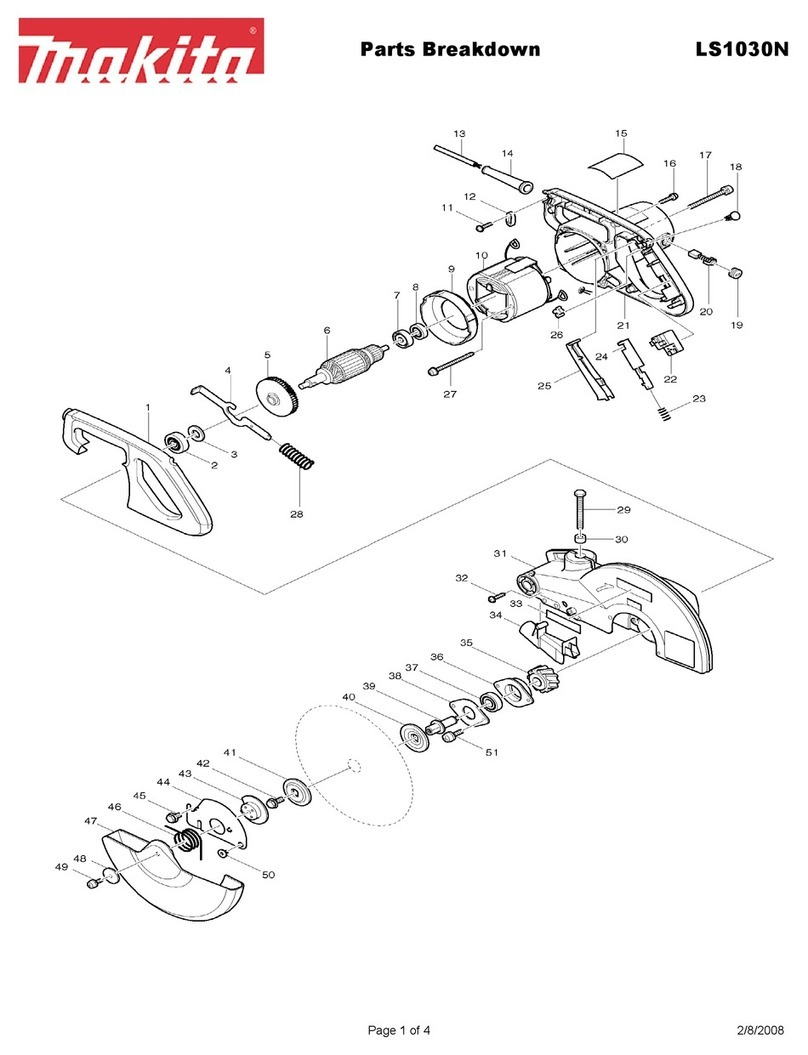

[3] DISASSEMBLY/ASSEMBLY

-1. Switch ............................................................................................................................5

-2. Starter............................................................................................................................7

-3. Rotor..............................................................................................................................11

-4. Gear box........................................................................................................................12

-5. Gear lock pin.................................................................................................................16

-6. Lower blade guard .......................................................................................................17

-7. Link................................................................................................................................18

-8. Up blade guard .............................................................................................................20

-9. Support arm..................................................................................................................23

-10. Working table and Base

..........................................................................................................

28

[4] ADJUSTMENT

-1. Preparation for adjustment.........................................................................................32

-2. Adjustment....................................................................................................................32

1. Adjustment for 90° angle......................................................................................32

2. Adjustment for 45° angle......................................................................................33

3. Rip fence ................................................................................................................34

4. Adjustment for the cutting range of blade..........................................................34

5. Adjustment for laser light.....................................................................................35

[5] Circuit diagram, Wiring diagram

-1. 220-240V area where Radio Interference Suppression is required .........................37

1. Circuit diagram

...................................................................................................................

37

2. Wiring diagram.....................................................................................................38

3. How to connect wires............................................................................................39

-2. 110V area where Radio Interference Suppression is required

.....................................

40

1. Circuit diagram

...................................................................................................................

40

2. Wiring diagram.....................................................................................................41

3. How to connect wires

.........................................................................................................

42

-3. 110V area.......................................................................................................................43

1. Circuit diagram

...................................................................................................................

43

2. Wiring diagram.....................................................................................................44

3. How to connect wires

.........................................................................................................

45