K & W Model Airplanes Inc.

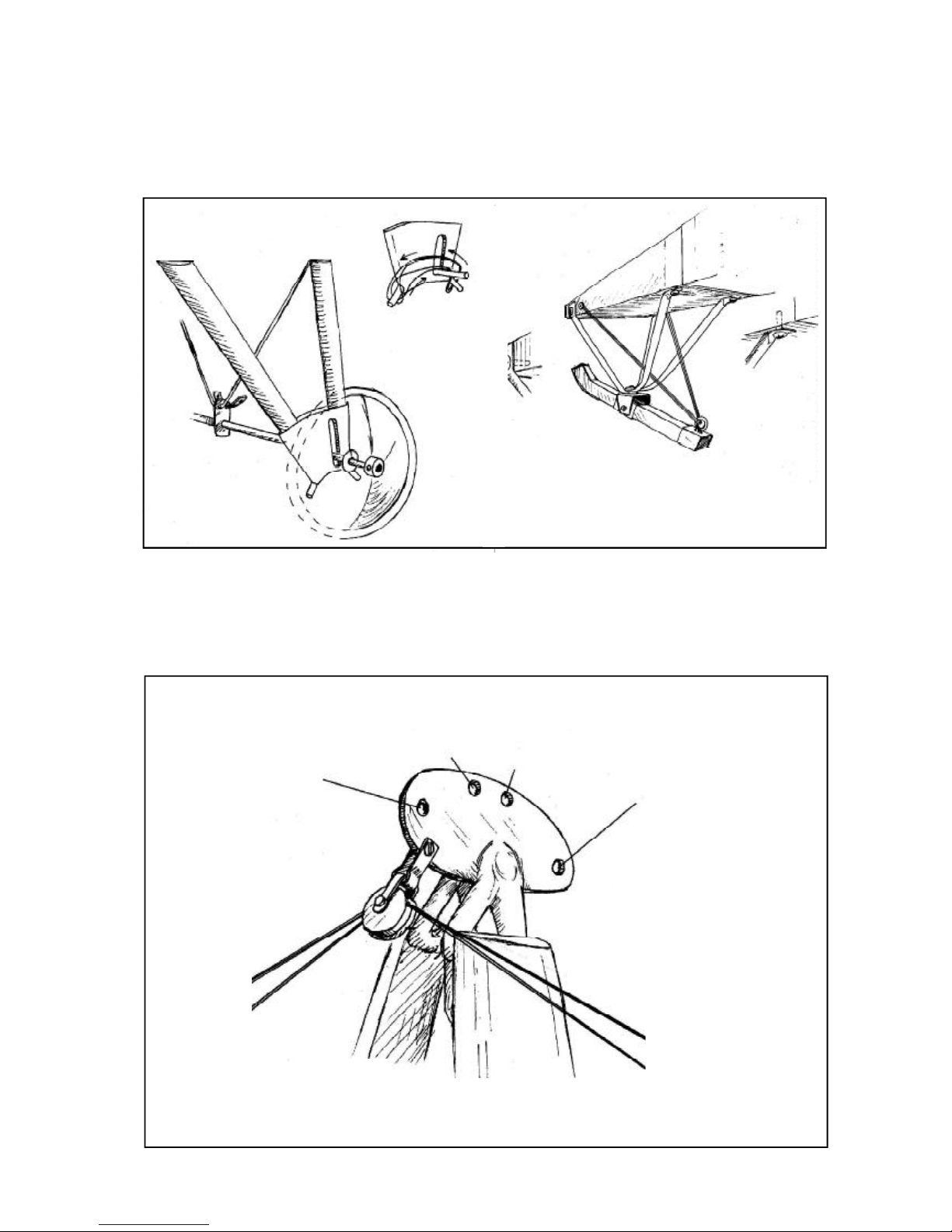

partofthe fuselage.Wiresareledfrom theservo

arm straight down to the arms of the wing

warping actuator. Stretch the wires and lock.

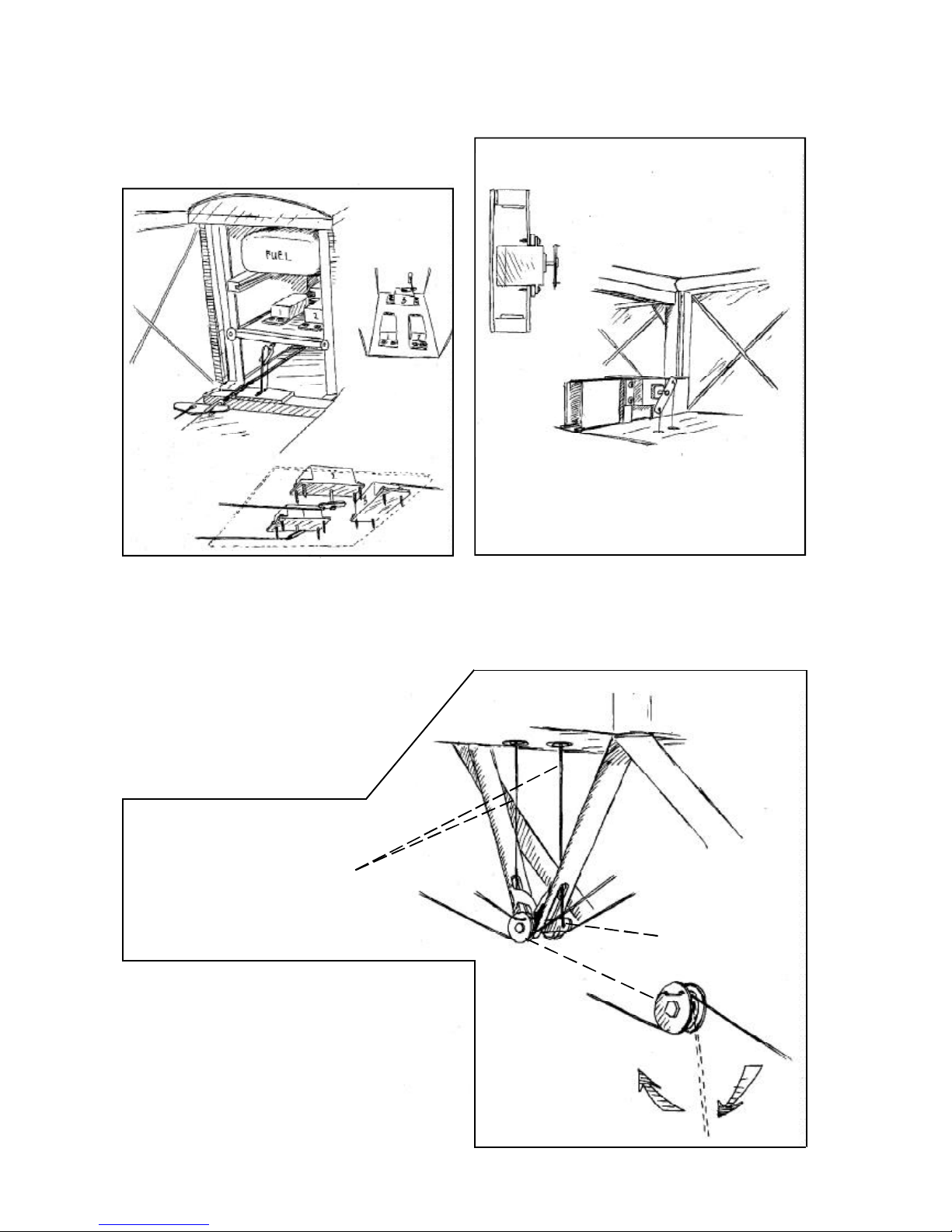

Theremaining servos are installed in the

servo tray and note that the tray is inverted!

Nextistheservofor the throttle. Connect

the wire arm to the servo and through the fire

walltothearmonthetrottlewithaballlink.Make

sure that is working freely.

Elevator servo is connected to the joy

stick, also with a ball link on the joy stick.

Rudder servo is connected in the same

fashion to the rudder bar.

Theupper tray contains the receiver and

the battery pack. The switch can be mounted

onthedash board orehidden under the cowlon

the upper tray and actuated by a push-rod

protrudingintothecockpit.

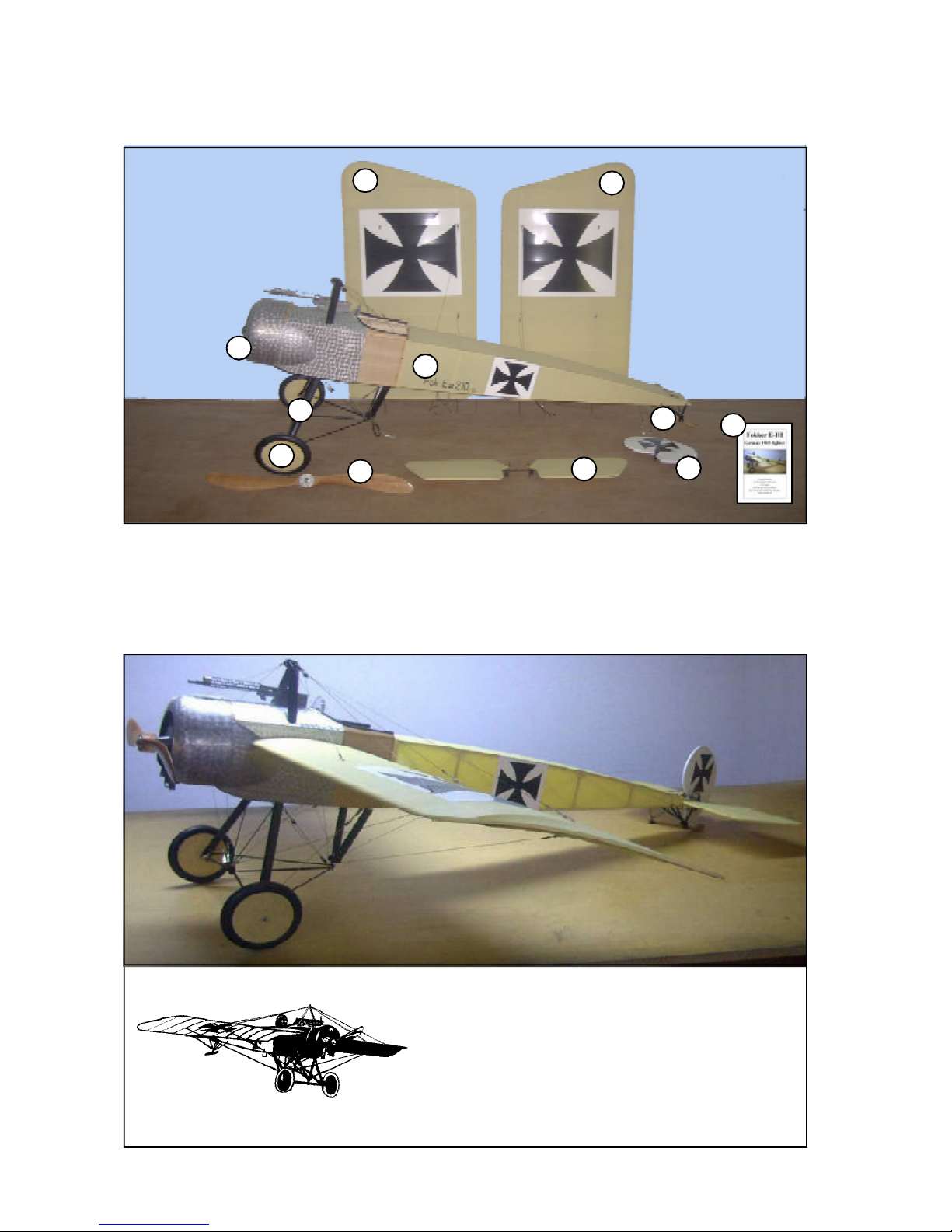

Installation of engine.

The engine mounts have been installed in

a unusual fashion for several reasons.

Theneedfor adequate cooling. Theaccess

totheglowplugwithouthoeinthecowlandfinally

togetthe carburator in linewith the center ofthe

tank.1.Removethe engine mountsanddrill and

taptheholesfor the engine. Placetheengineas

close to the fire wall as possible. If you have to

relocate the engine mounts, you can do so and

theblind nuts are not securedwith glue. Should

you desire to install a 4-stroke engine you may

have to make an opening in the firewall for the

carburator and a small "box" so that no fuel

spreadsintothe fuselage. On thefullsizeplane,

the carburator is located between the two air

intake tubes!

2. Drill the holes from the tank to the

carburator, preassure tap and the filling cap.

3.Installtheengineandconnectthethrottle

servo.

4. Make cut outs in the dummy engine so

that this will fit in front of your engine. You may

haveto remove 1 complete cylinder to allow for

the cooling air to pass the engine head. This

"surgery" isexecuted by removing a little at the

timeand checking. Whenyou are satisfied with

the fit and openings, screw the dummy engine

ontothe engine mounts using 3 mm screwsand

washers.

5. Reinstall the engine cowl using 3 #2

sheet metal screws.

Installation of servos, tank, battery and

receiver.

The aileron servo is installed in the lower

partof the fuselage

The trottle servo and the rudder servo

are installed in the servo tray. The tank is

positioned at the side of these servos.

The elevator servo is is installed inverted

inthe tray.

Battry pack and receiver are positioned

intheuppertray.

The switch ismounted on the dash board.

1. Attach a ball link head to joystick and

rudder bar in the appropriate holes. You may

havetoenlargethe holes to takethescrewfrom

the ball link (Dubro #189 set of 2).

2.Installtheservosfor rudder and elevator

and temporarily connect the servo arms to the

ball links. Deflection for elevator is 20° up and

downand for rudder30° right and left..

3. Install and connect the throttle servo in

thefashionyouprefer.

4. Install the tank in the available space in

front of the rudder and throttle servos..

5.Installtheaileronservoin the lower wing

usingservo tape. The servo arm attaches tothe

Kwick-link allready installed on the aileron

connectionrod. Deflectionshouldbe20° upand

down.

6. Fasten the upper servo tray and make

the final connections.

7.Installtheradioswitchonthedashboard.

8. Place the receiver and the battery pack

in the upper tray, wrapped in foam rubber and

secure with rubber bands.

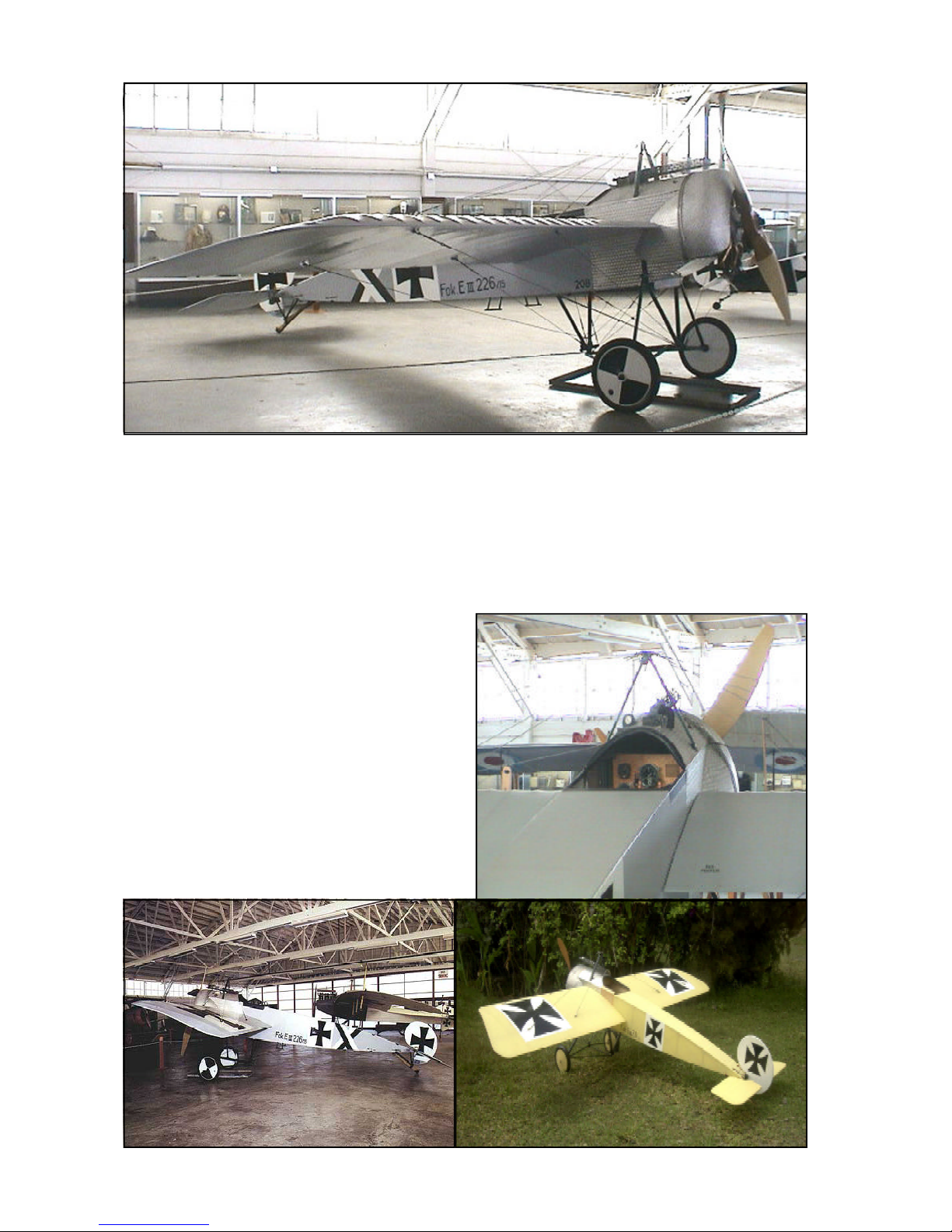

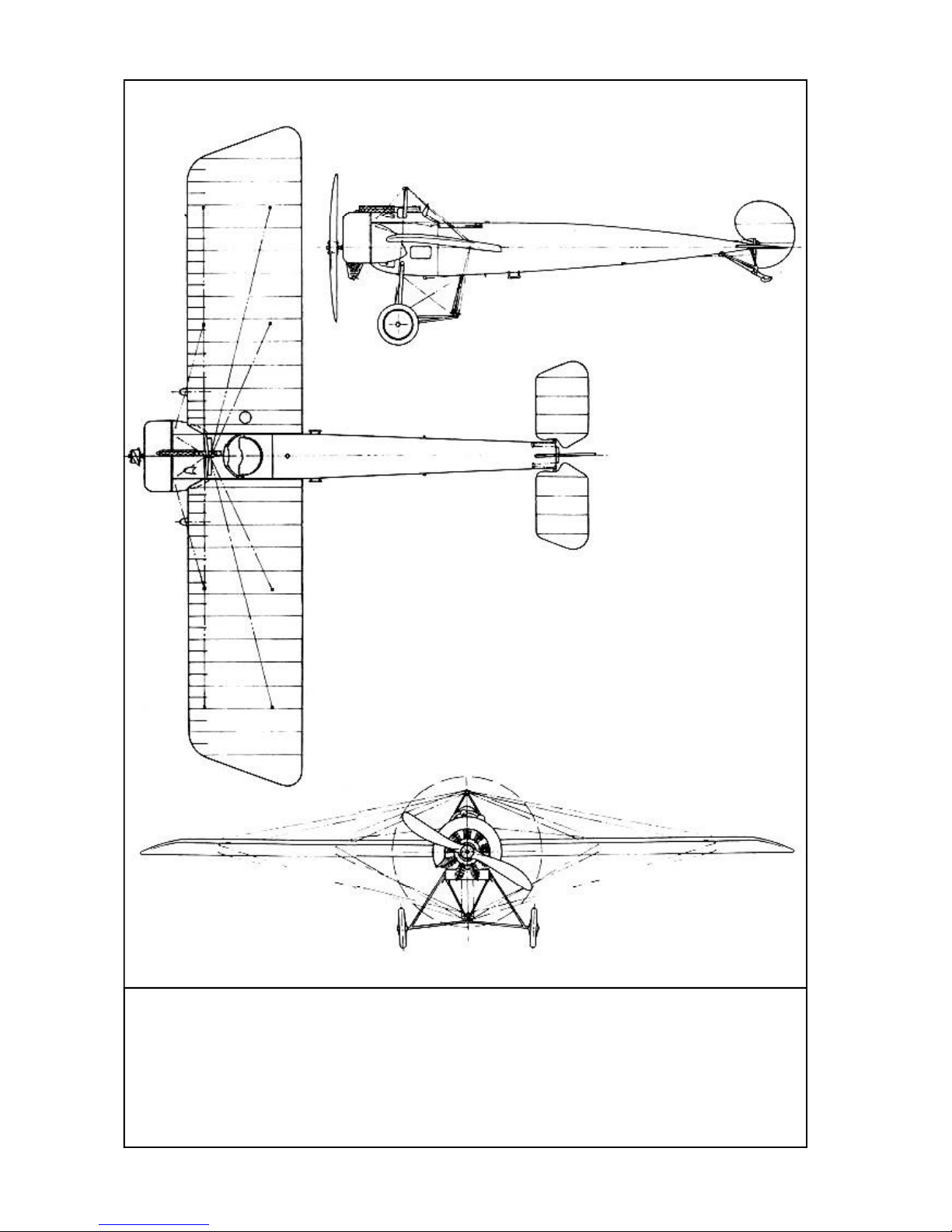

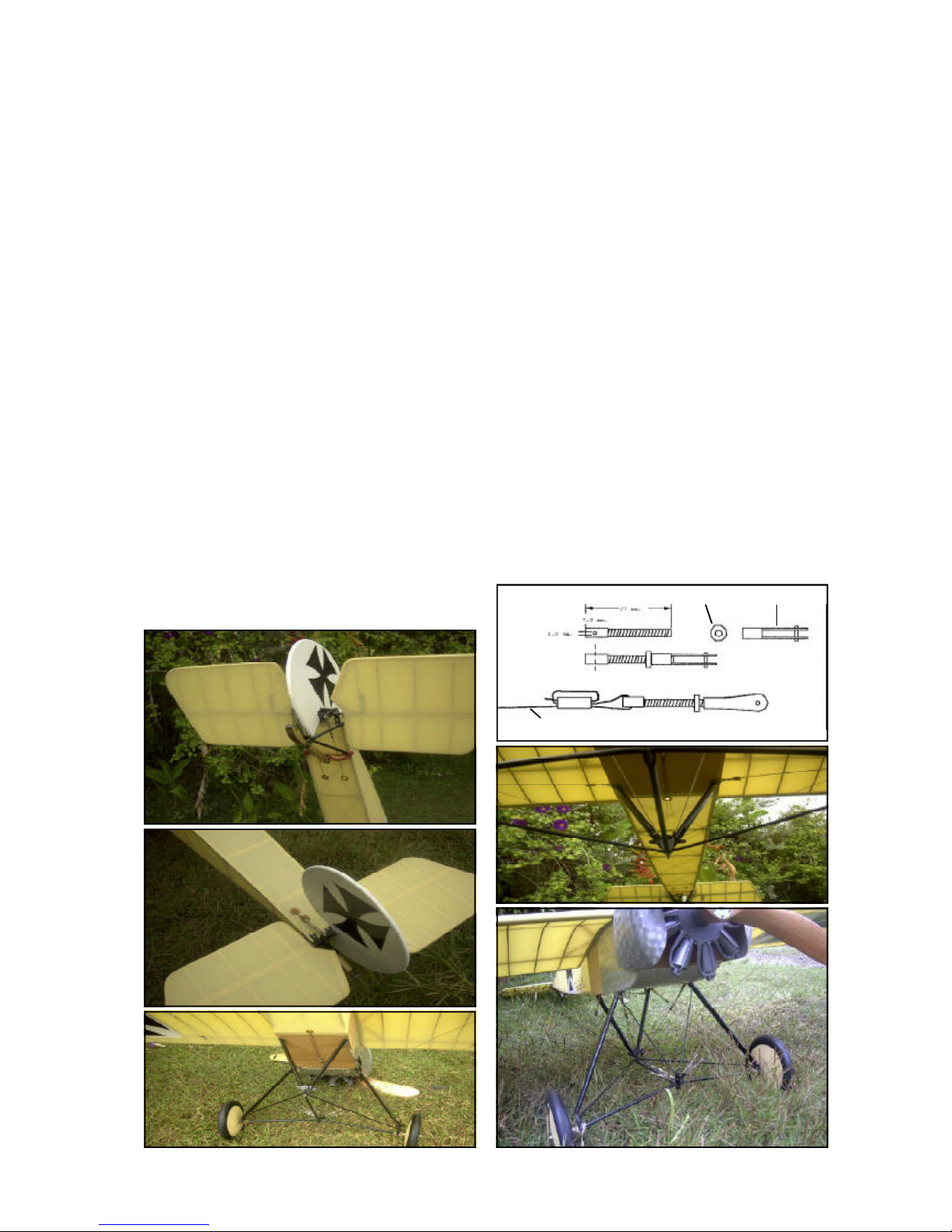

Assembly of the Fokker E III

All parts have been assembled at the

factoryand onlydisassembledfortransportation.

Rudder and elevator wires are factory

adjusted but may need some tensioning

adjustmentafter a while.

1. Fasten the elevator to the fuselage with

4screwssupplied. Slide the upperelevatorwires

through the holes in the fuselage and attach to

theupper elevator horns.

2. Install the rudder assy by inserting the

music wire the hole in the rudder and secure

with a stopper screw in the tail skid assy.

3. Attach the lower elevator wires and the

rudder wires. The upper set of wires are for the

rudder.Check theaction ofelevator andrudder.

The elevator is actuated with the joy-stick and

the rudder with the rudder bar.