●

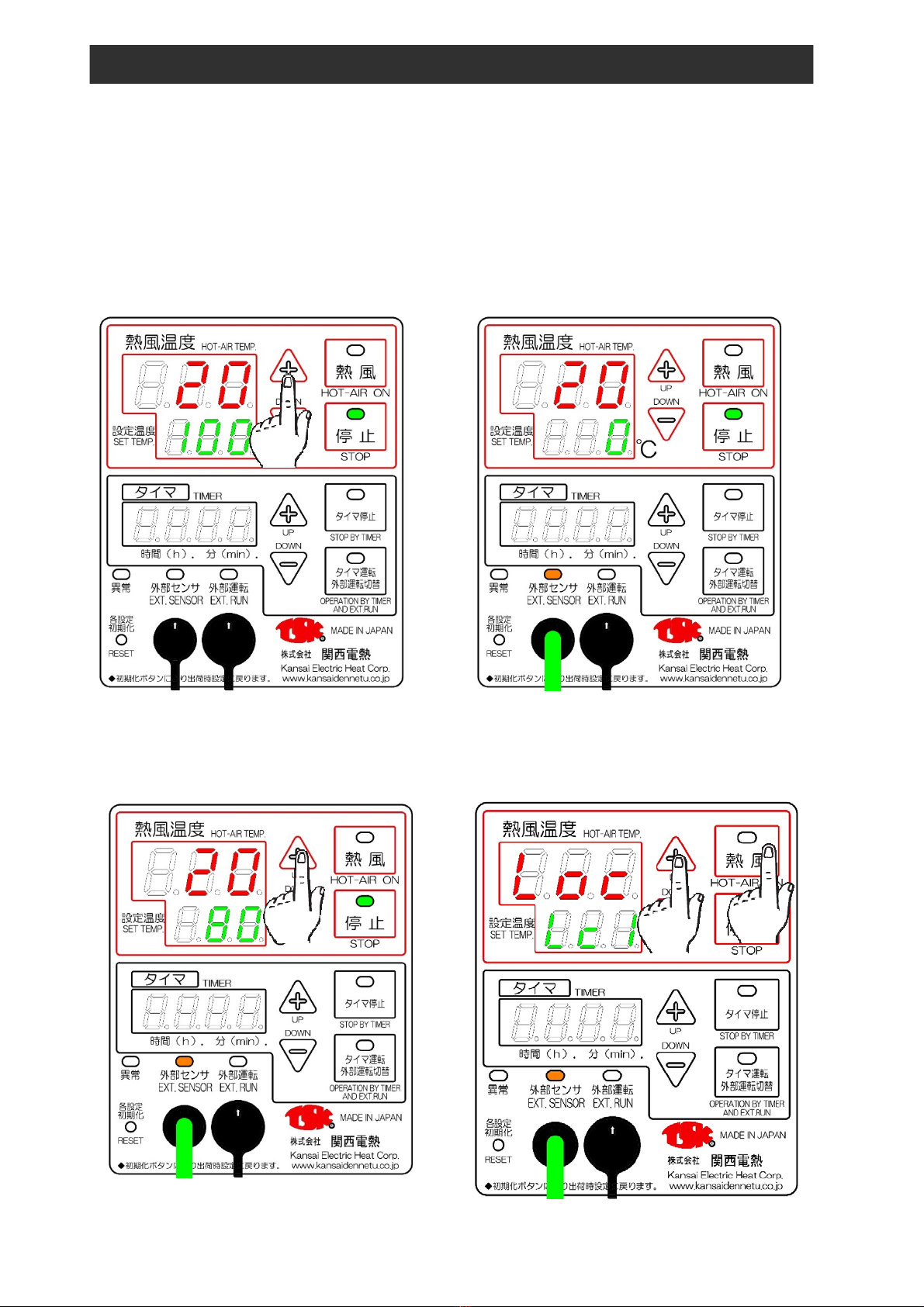

①②③

④⑥

⑤

※※

⑦⑧⑨

※※※

※Please contact us for manual recovery.

OUTLET SENSOR BURNOUT

Abnormal temperature inside

multi-dryer

The ambient temp is high, the hot air leaking

from the outlet flows back into the operation

panel, and the effect of heat dissipation from

the furnace body due to the installation on

the top of the furnace body, etc.

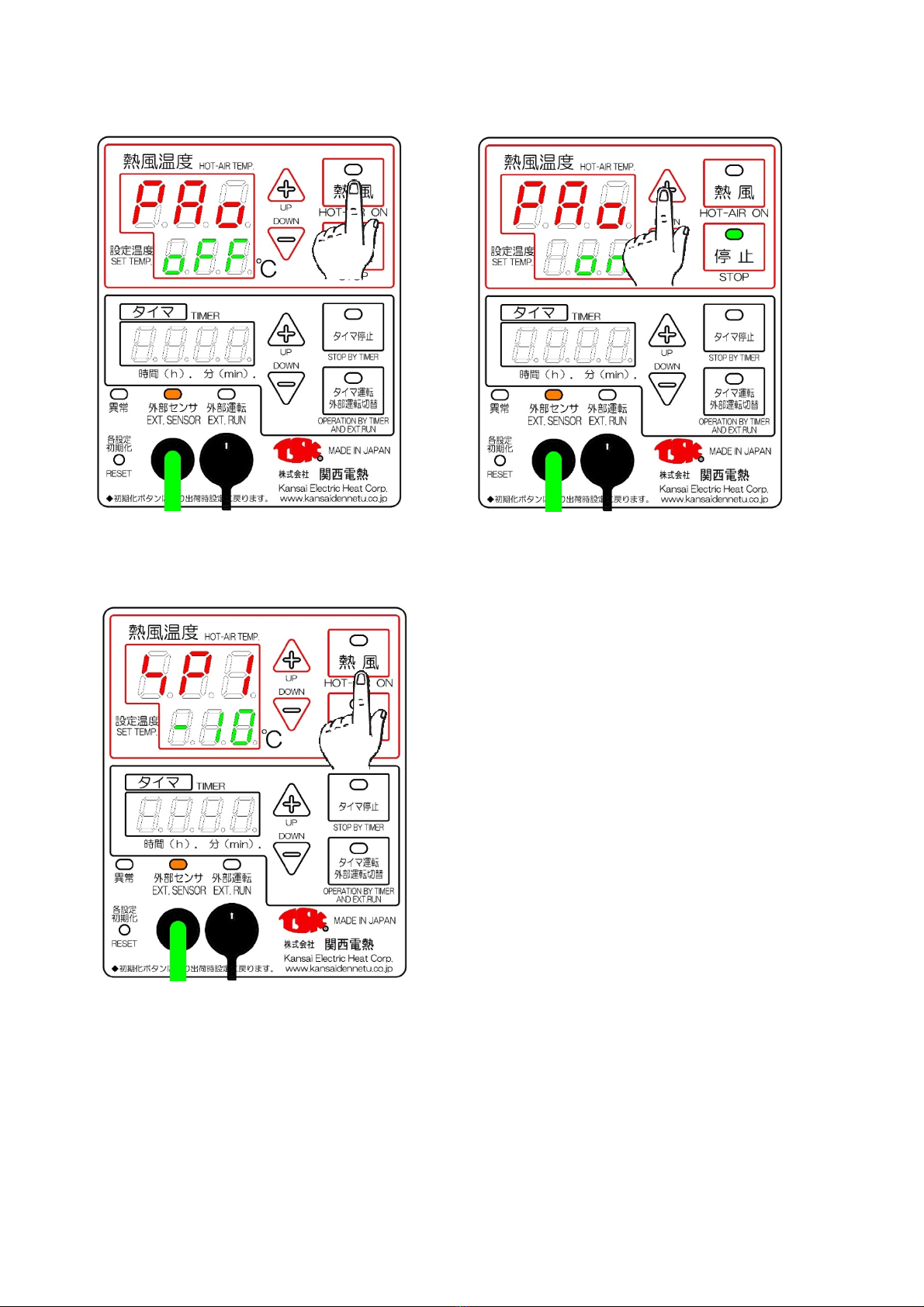

Overheat prevention sensor

minus display

(For heater case temp sensing)

When the inside of the heater becomes

abnormally high temperature, the abnormal

lamp (red) lights up, "ALM" flashes in the hot

air temperature section, and "Tcb" flashes in

the set temperature section.

When the heater case becomes abnormally

high temperature, the abnormal lamp (red)

lights up, "ALM" flashes in the hot air

temperature section, and "TPb" flashes in the

set temperature section.

When the discharge temperature

exceeds the upper limit, the abnormal

lamp (red) lights up, "ALM" flashes in

the hot air temperature section, and

"TcA" flashes in the set temperature

section.

《MAIN CAUSES》 《MAIN CAUSES》 《MAIN CAUSES》

Insufficient air volume due to clogging of

the suction port filter, excessive

resistance on the discharge side, etc.

Air volume supply stopped due to

clogging of the intake filter, excessive

resistance on the discharge side, lock of

the blower, etc.

OVERHEAT OVERHEAT OUTLET TEMP UPPER LIMIT

(For detecting the temp inside the heater)

5.Each abnormality indication

When the multi-dryer is abnormal, the details of each abnormality are displayed and the operation is stopped (only the

internal temperature abnormality is in the ventilation operation state). Be sure to remove the abnormality and then

restart the operation by turning on the power switch again. (Depending on the abnormality, it may be possible to

recover with the stop switch. Also, only the overheat for detecting the temperature of the heater case will be manually

restored.) ..

Clogged suction port filter, insufficient air

volume due to excessive resistance on the

discharge side, or exceeding the upper limit of

the discharge port temperature when using an

external sensor

OVERHEAT PREVENTION

SENSOR BURNOUT

When the internal temp of the multi-

dryer rises above + 65℃, the abnormal

lamp (red) flashes, "oH" flashes in the

hot air temp section, and "ALM" flashes

in the set temp section.

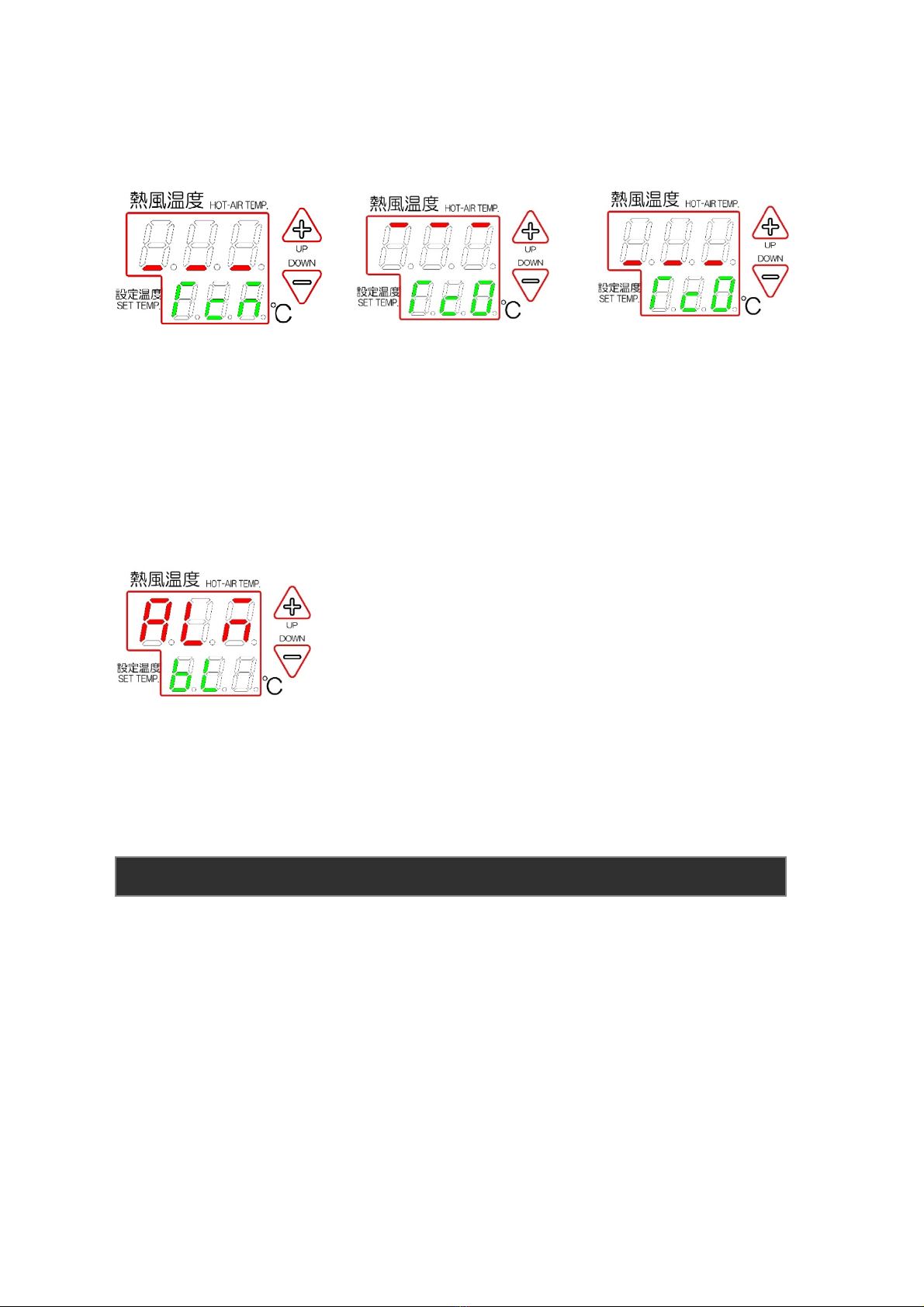

If the outlet sensor is disconnected, the

abnormal lamp (red) flashes, "----"

flashes in the hot air temp section, and

"TcA" flashes in the set temp section.

If the overheat prevention sensor is

disconnected, the abnormal lamp (red)

flashes, "----" flashes in the hot air

temp section, and "Tcb" flashes in the

set temp section.

When the overheat prevention sensor

temp drops below -15℃, the abnormal

lamp (red) flashes, "----" flashes in the

hot air temp section, and "Tcb" flashes

in the set temp section.

《MAIN CAUSES》 Please turn off the power and

request repair.

Please turn off the power and

request repair.

Multi-dryer internal temp sensor

burnout

outlet sensor minus display

When the outlet sensor temp drops

below -15℃, the abnormal lamp (red)

flashes, "----" flashes in the hot air

temp section, and "TcA" flashes in the

set temp section.

If the internal temp sensor of the multi-dryer

is disconnected, the abnormal lamp (red)

flashes, "----" flashes in the hot air temp

section, and "TcM" flashes in the set temp

section.

Please turn off the power and

request repair.

After checking the installation

ambient temperature, if it does not

improve, please contact us for

repair.

After checking the installation

ambient temperature, if it does not

improve, please contact us for

repair.

-4-