314

TIMER ADJUSTMENT

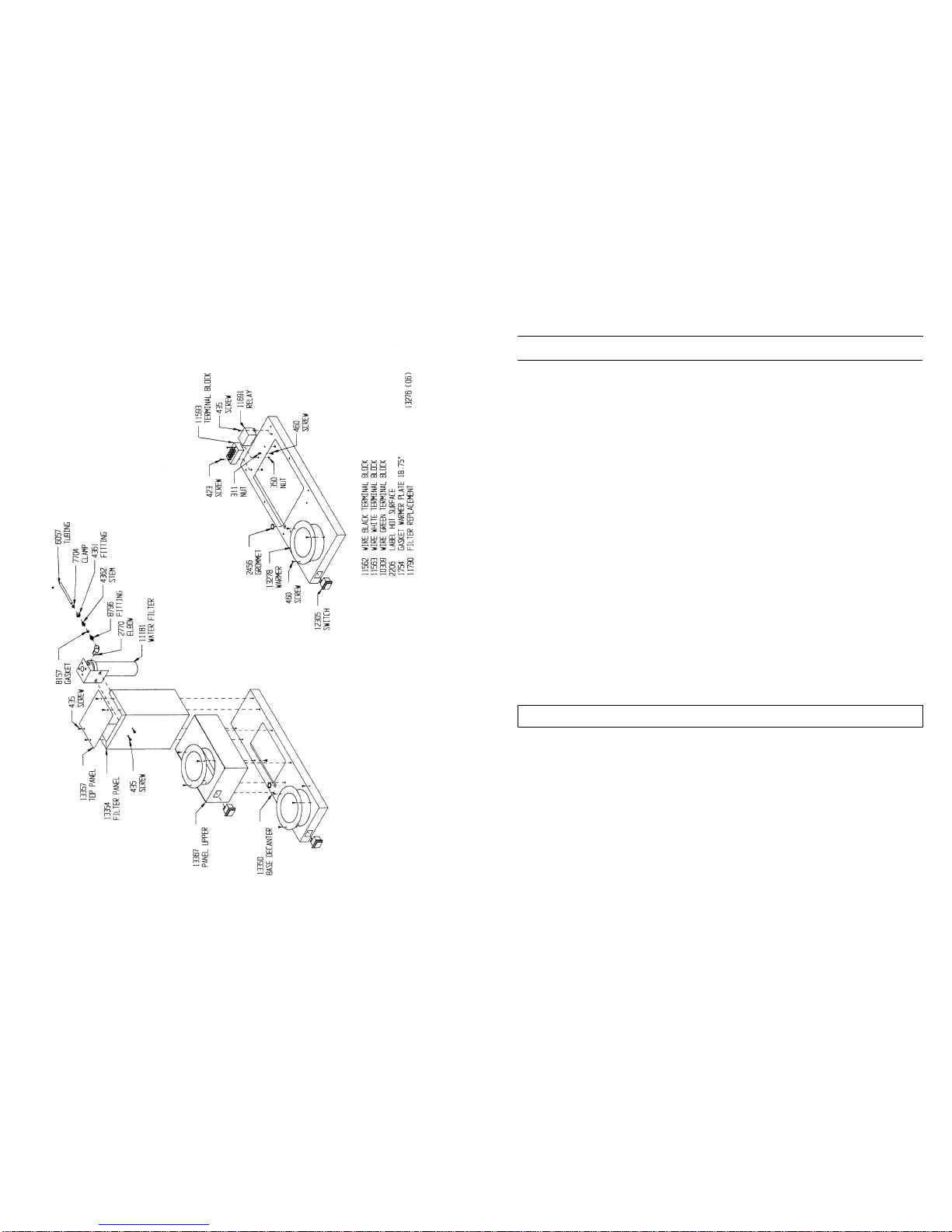

1. Remove plugs from correct hole on front of dispenser. (See Fig. 4)

Note: Four Timer holes; On the left the small one is on top, the large one is on bottom

On the right the small one is on top, the large one is on bottom

2. Adjust by using a small flat blade screwdriver . Turn timer stems clockwise to increase or

counterclockwise to decrease the time range. (See Fig. 5)

WARRANTY

Karma warrants, except as hereinafter provided, as follows:

1. That each product sold hereunder which is manufactured by KARMA shall be free of defects in materials or workmanship

for a period of 1 year after shipment thereof. This warranty is void in cases of damage in transit, negligence, faulty

installation, abuse, abnormal usage, misuse, accidents, or failure to maintain the product according to the instruction

manual provided. This warranty does not cover malfunctions due to dirty or clogged waterlines, lime-related conditions or

other conditions related to the local water supply. THERE IS NO OTHER EXPRESS WARRANTY; KARMA HERBY

DISCLAIMS ALL IMPLIED WARRANTIES INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND

FITNESS FOR ANY PARTICULAR PURPOSE INDICATED BY PURCHASER TO KARMA.

2. The sole obligation of KARMA hereunder shall be limited to repair or replacement, at the option of KARMA, of any

defective products expressly warranted under the terms of this Agreement. This obligation does not include the cost or

expense of travel time by service personnel, but does include the cost or expense of actual time spent to remove and

replace a defective part or product. This obligation shall be conditioned upon receipt of KARMA of written notice

specifically describing any defect promptly after discovery. KARMA reserves the right or inspect products claimed to be

defective and covered by warranty, either at Purchaser’s location or at KARMA’s principal place of business in

Watertown, Wisconsin, freight pre-paid; the place of such inspection to be determined solely at the option of KARMA.

Final determination as to whether a product is actually defective rests with KARMA. A defective product shall not be

otherwise returned to KARMA unless specifically authorized by KARMA.

3. KARMA will not assume responsibility, pay expenses or accept invoices for unauthorized service, repairs, or replacement

with respect to its products, even if defective. KARMA assumes no liablity for labor charges incidental to the adjustment,

service, repairing, removal or replacement of its products, or for the expense of repairs or any other direct or indirect

costs incurred by Purchaser with respect to such products, except when approved in advance by KARMA.

LIMITATION OF LIABILITY

NO CLAIMS MADE HEREUNDER BY THE PURCHASER, WHETHER AS TO GOODS DELIVERED OR FOR NONDELIVERY

SHALL BE GREATER THAN THE PURCHASE PRICE OF THE GOODS IN RESPECT OF WHICH SUCH CLAIM IS MADE.

KARMA SHALL UNDER NO CIRCUMSTANCES BE LIABLE FOR ANY LOSS OF PROFITS OR ANY OTHER INCIDENTAL

OR CONSEQUENTIAL DAMAGES, OR FOR DAMAGES IN THE NATURE OF PENALTIES.

365 DAYS/24 HOUR FAX BACK SERVICE

TO QUICKLY OBTAIN COPIES OF ONE OR MORE OF THE PAGES OF THIS MANUAL, CALL 1-800-

558-9565 OR 920-261-1424 AND SELECT EXT.152 ON KARMA’S GREETING MENU. THEN FOLLOW

THE VOICE PROMPT INSTRUCTION TO HAVE THE DESIRED INFORMATION AUTOMATICALLY

FAXED BACK TO YOU.

Fig. 4

Fig. 5

NOTE:

1.The standard time ranges allow for vessel sizes from 25 ozs. to 75 ozs.

2. Partial vessel sizes can be obtained simply by depressing the brew switch

during a brew cycle.

TIMER

HOLES