6

• Donotusethistypeofmachineforsweepingawaydebris.

• Donotusetheunitwhenyouaretired,illorundertheinuenceofmedication,drugsoralcohol.

• Usenyloncuttingheadwhichisfreeofdamage.Ifastoneoranyotherobstacleishit,stoptheengine

and check the nylon cutting head. A broken or unbalanced nylon cutting head must never be used.

FOLLOW INSTRUCTION FOR CHANGING ACCESSORIES.

• Donotstoreinaclosedareawherefuelvaporscanreachanopenamefromhotwaterheaters,heaters,

furnaces, etc. Store in a locked, well ventilated area only.

• ensuresafeandproperperformanceofyourproduct.Thesepartareavailablefromyourdealer.Theuse

of any other accessories or attachments may cause a potential hazard or injury to the user, damage to

the machine and void this warranty.

• Cleanthemachinecompletely,especially,thefueltank,itssurroundings,andtheaircleaner.

• Whenrefueling,besuretostoptheengineandconrmthatitiscooleddown.Neverrefuelwhenthe

engine is running or hot. When gasoline spills, be sure to wipe it up completely and properly dispose of

those materials before starting the engine.

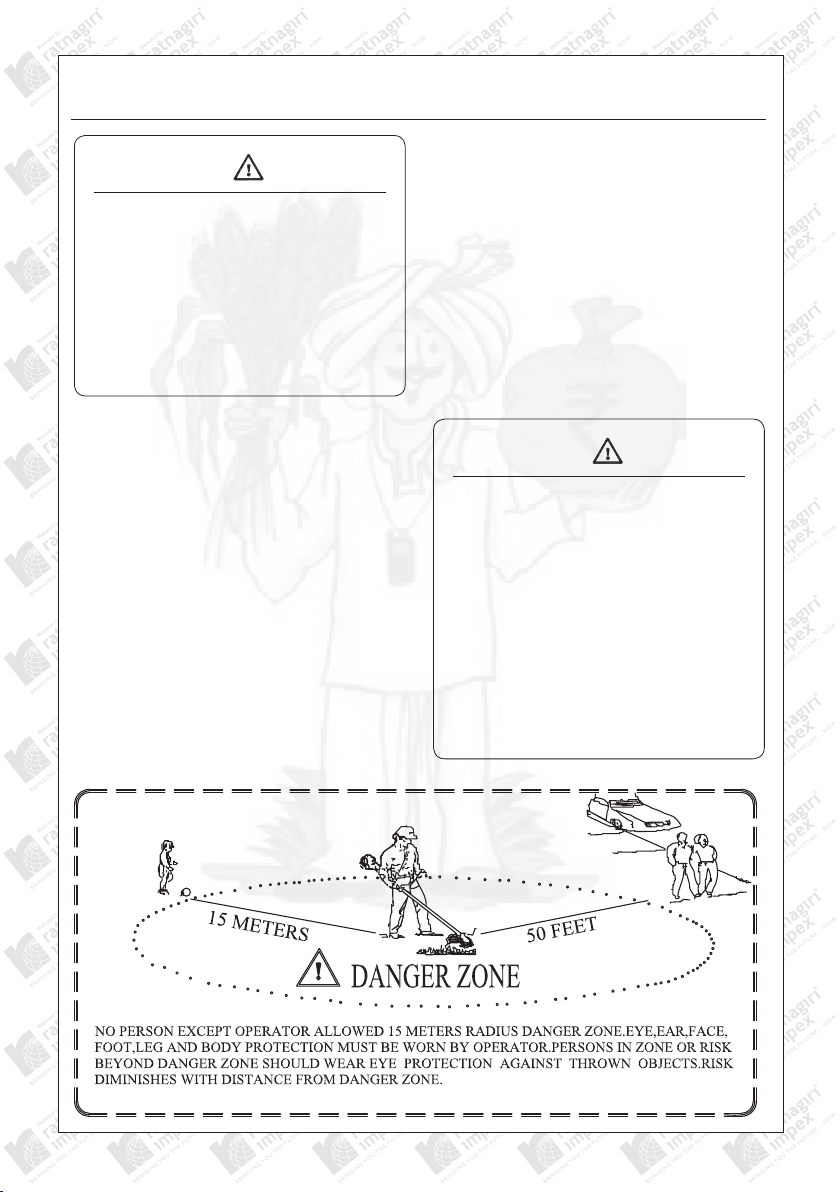

• Stayclearofotherworkersorbystandersbyatleast15meters/50feet.

• Wheneverapproachinganoperatorofthemachine,carefullycallhisattentionandconrmthatthe

operator stops the engine. Be careful not to startle or distract the operator which can cause an unsafe

situation.

• Nevertouchthenyloncuttingheadwhenever the engine isrunning.Ifitisnecessarytoadjust the

protector or nylon cutting head, be sure to stop the engine and confirm that the nylon cutting head has

stopped running.

• Theengineshouldbeturnedoffwhenthemachineismovedbetweenworkareas.

• Becarefulnottohitthenyloncuttingheadagainststones,ortheground.Unreasonableroughoperation

will shorten the life of the machine as well as create an unsafe environment for yourself and those

around you.

• Payattentiontolooseningandoverheatingofparts.Ifthereisanyabnormalityofthemachine,stop

operation immediately and check the machine carefully. If necessary, have the machine serviced by a

authorized dealer. Never continue to operate a machine which may be malfunctioning.

• Instart-uporduringoperationoftheengine,nevertouchhotpartssuchasthemufer,thehighvoltage

wire or the spark plug.

• Aftertheenginehasstopped,themuferisstillhot.Neverplacethemachineinanyplaceswherethere

are flammable materials (dry grass, etc.), combustible gasses or combustible liquids.

• Payspecialattentiontooperationintherainorjustaftertherainasthegroundmaybeslippery.

• Ifyousliporfalltothegroundorintoahole,releasethethrottleleverimmediately.

• Becarefulnottodropthemachineorhititagainstobstacles.