[5]

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

マスターページにある

オブジェクト

Shift+Ctrl を押しながら

選択ツールで選択可

7. Safety parts for periodic replacement

7. Safety parts for periodic replacement(T218341-001-0E)

For the long-term safe operation of the machine, we ask you to inspect and service it regularly. However it is difficult to

evaluate the lifespan of parts by external visual inspection, so certain important parts such as the parts related to a fire

should be replaced at set intervals regardless of their apparent condition. If inspection and servicing reveals any

abnormality whatever in these parts, replace them even before their regulation time.

Ask your authorised KATO dealer to carry out the replacement of these safety parts.

Fuel system: Every 2 years or 4000 hours of operation, whichever reaches sooner.

・Fuel hose (fuel tank – fuel filter – engine – fuel tank, fuel pump related)

Hydraulic system: Every 2 years or 4000 hours of operation, whichever reaches sooner.

・Pump suction hose (oil reservoir ―hydraulic pump)

・Pump discharge hose (hydraulic pump ―control valve)

・Line hose for swing motor (control valve ―swing motor)

・Line hose for boom cylinder (control valve ―boom cylinder)

・Line hose for arm cylinder (control valve ―boom piping, boom piping ―arm cylinder)

・Line hose for bucket cylinder (control valve ―boom piping, boom piping ―bucket cylinder)

・Engine oil remote hose

・Additional attachment hose

Cooling system: Every 2 years or 4000 hours of operation, whichever reaches sooner.

・Heater hose (engine ―air conditioner unit)

Inside the engine compartment: Every 5 years

・Sound absorbing material

Others: Every 3 years

・Seatbelt

You must also inspect hydraulic hoses and fuel hoses during the following regular inspections.

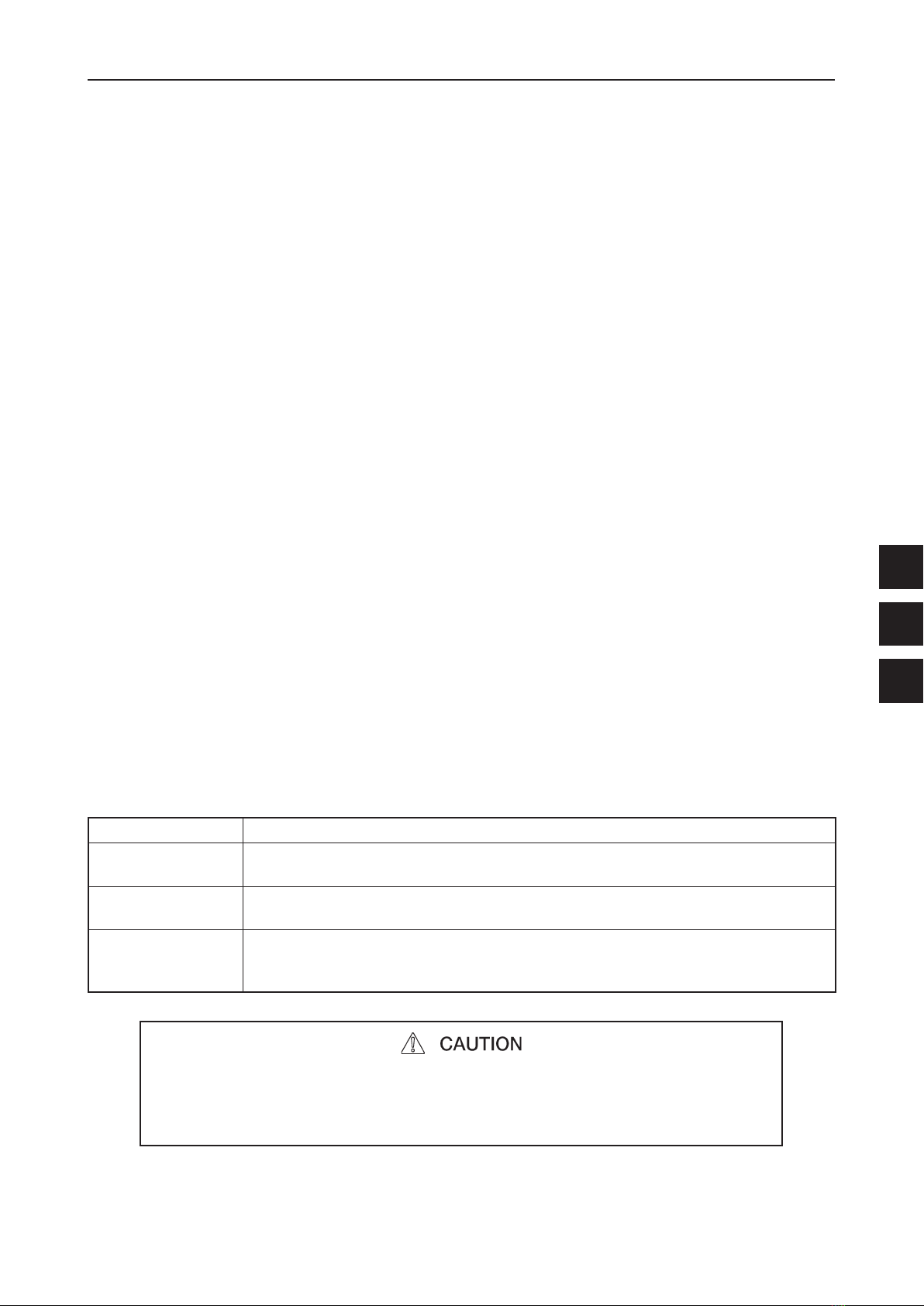

Inspection interval Inspection item

Preoperational

inspection ・Oil leakage from the joints and caulked sections of fuel or hydraulic hoses

Monthly inspection ・Oil leakage from the joints and caulked sections of fuel or hydraulic hoses

・Damage to fuel or hydraulic hoses (cracks, wear, tearing)

Yearly inspection

・Oil leakage from the joints and caulked sections of fuel or hydraulic hoses

・Interference, collapse, deterioration, twisting, damage (cracks, wear, tearing)to fuel or

hydraulic hoses

(01EE-0018-0E)

1. Replace O-rings, gaskets etc. at the same time as you replace hoses.

2. If you find deformation or cracking of hose clamps when you inspect or replace hoses, you

should also replace the affected clamps.

(01E0-0019-0E)