KAUO HENG COMPUTERIZED FLAT KNITTING MACHINE

KH-300 OPERATION MANUAL

2

2. Specification

MODEL KH-300

GAUGE 3G, 3.5G, 4G 5G, 7G, 10G, 12G, 14G

46”(117CM)60”(152CM)

KNITTING WIDTH

80”(203CM)80”(203CM)

60”:Double system one carriage

Single system, twin carriage

80”:Single system, twin carriage.

CAM SYSTEM

Knitting system three-way technique and transfer with split stitch function.

KNIITING SPEED Max 1.2 m/sec.

YARN CARRIERS 12 yarn carriers on 3 double rails.

NEEDLE SELECTION Full jacquard selection via special solenoids.

TRANSFER Simultaneous transfer, front or back, independent of carriage direction.

Split knitting.

NEEDLE BED Replaceable segment needle bed.

SINKER SYSTEM Moveable sinker equipment.

STITCH DENSITY 30 levels independent selection, electronic control with stepping motor

00-180 steps.

RACKING Racked by servo motor and high precision ball screw system.

Racking 1/2 pitch also available from any position.

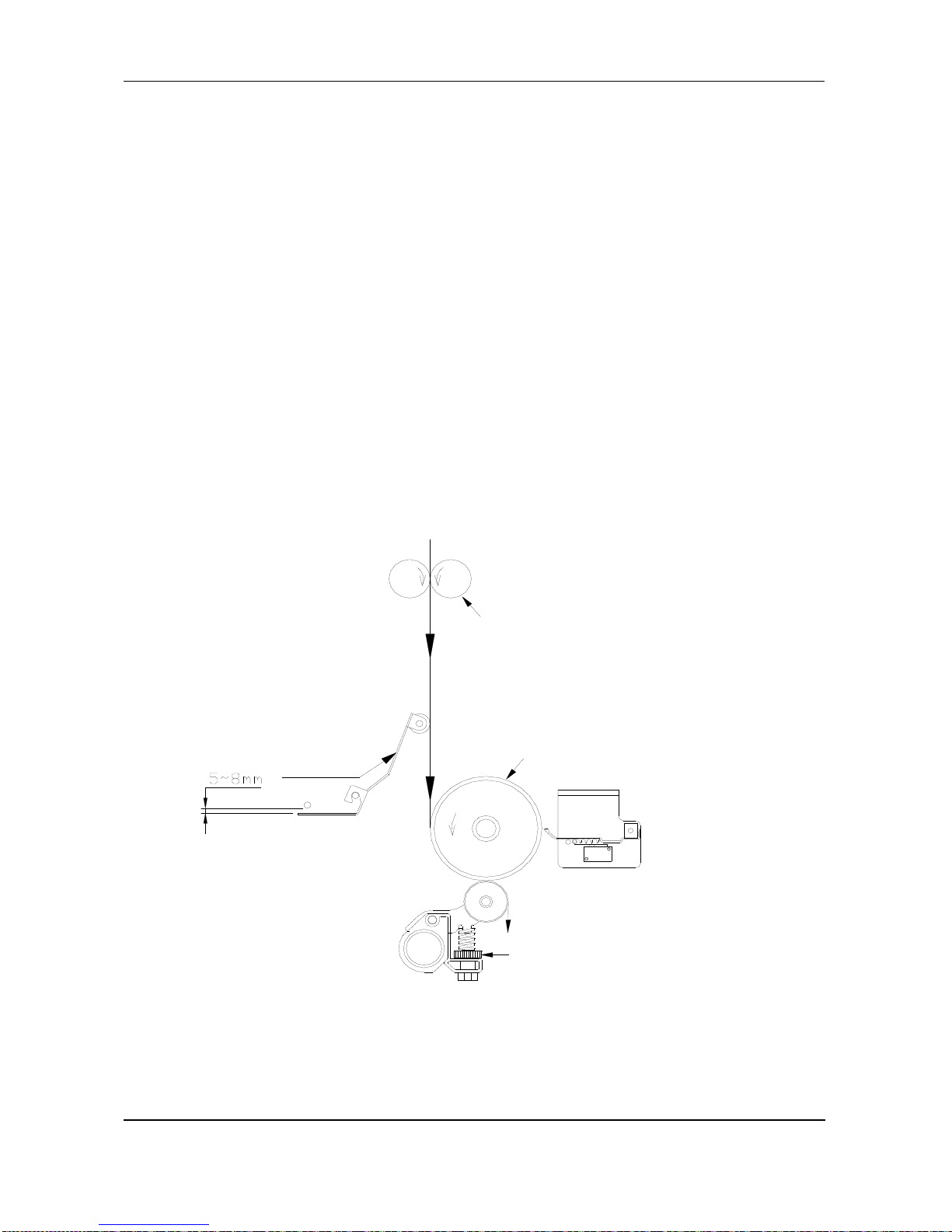

FABRIC TAKE DOWN Main roller / Sub roller:

32 levels changeable speed, automatically adjustable on each level.

STOP MOTION Yarn break, knot, press off, needle break, shock, over torque, piece count,

over run, program error etc.

DRIVE AC servo motor, tooth shape driving belt, no oil needed.

Variable adjustable programmable speed levels.

TOP TENSIONS Electronic top tensions easy to thread the yarn through.

YARN FEED UNIT Auto positive feeding device on each left / right side.

SAFETY COVER Full safety cover for anti-noise and dust proofing.

Emergency stop buttons.

OPERATION LAMP Green: normal operation.

Yellow: abnormal / manual stop.

FLUORESCENT LAMP Inside safety cover and take-down.

CONTROLLER

DATA INPUT USB

OPERATION &DISPLAY LCD display screen, Chinese and English versions available.

PATTERN MEMORY 1024 x 4096 huge memory

POWER 3 phase AC 220V 50 / 60 HZ