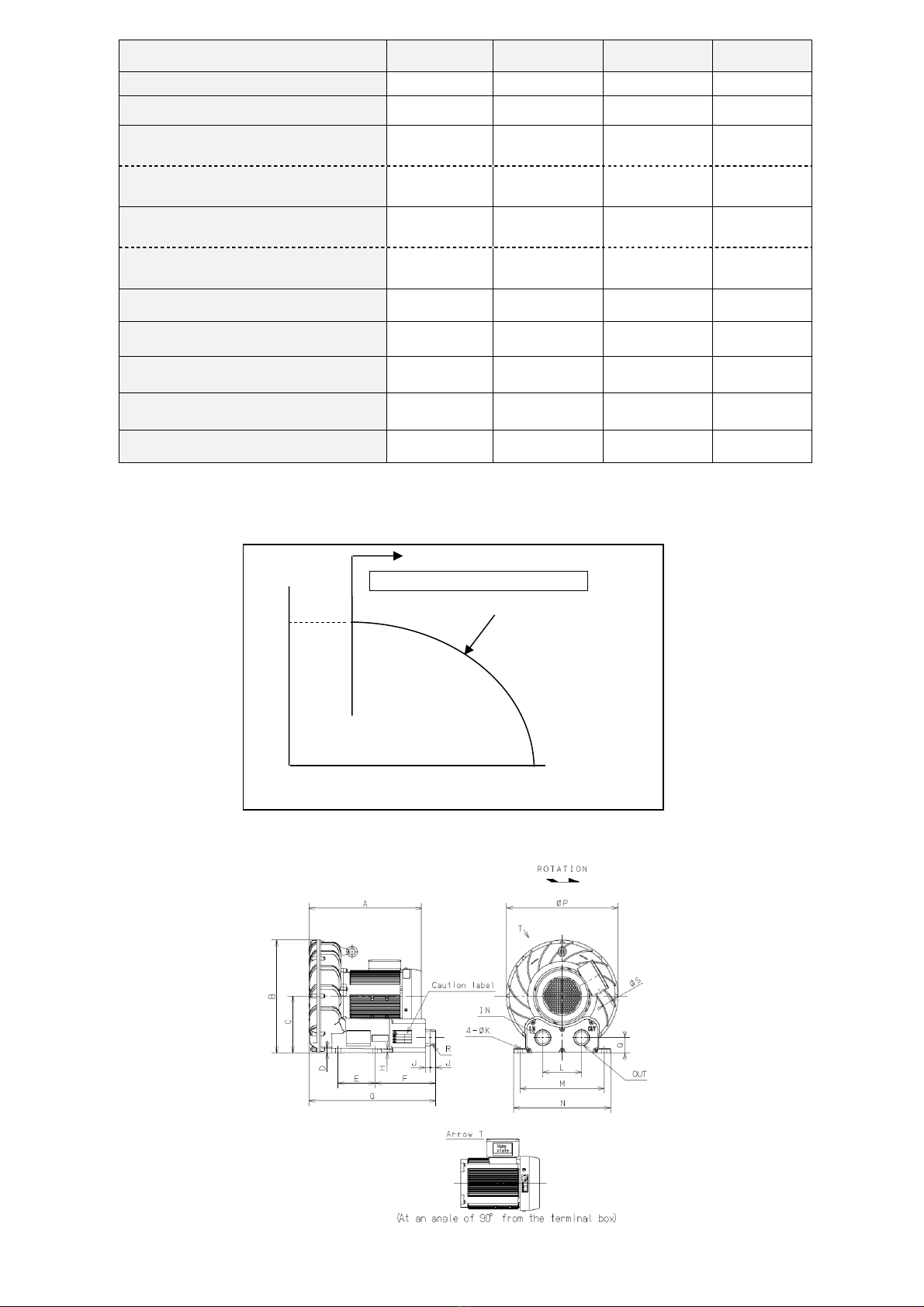

― ―

No.

Name Material No. Name Material

1 Bearings ― 9 Bolt SWRM

2 Bearings ― 10 Casing cover FCD500

3 Motor bracket FC200 11 Support SPCC

4 Casing ADC12(AC4A) 12 Sound absorbing material PUR(MF)

5 Spacer C2801P 13 Case cover ADC12(AC4A)

6 Impeller ADC12(AC4A) 14 Fan PA

7 Impeller washer SPCC 15 Fan cover SPCC

8 Washer with outer claw SPCC

(Note) The specifications and structure, etc., are subject to change without notice.

※( ) is for U2G-370B series.

3.2 Standard attachment

Name Q’ty

Instruction Manual 1

4

$$

●Before hoisting the blower unit during unloading, loading, and installation, check the product

catalog, the installation drawing, and instruction manual, etc., to verify the blower unit weight

and the hoist method. Do not attempt to hoist a blower unit that exceeds the hoist’s rated

load. Incorrect hoisting can result in drops or injuries.

●Security install the blower as explained in the instruction manual. Install the blower horizontally

and secure it with bolts. Improper installation could result in electric shocks, fires or injuries

from dropping.

●Install the product according to applicable laws and regulations (Electrical Installation

Technical Standards, Wiring Regulations). Failure to do so is not only illegal, it may result in

air leaks, electric shocks or injuries.

●Do not install in places such as machine or chemical plants where harmful gases from acids,

alkalis, organic solvents, or paints, or gases containing corrosive elements are produced, or in

dusty locations. Failure to observe this could lead to earth leakages or fires.

●Do not incinerate resin and rubber parts on site.There is a risk of generating harmful gas.

Please check with each local government for the processing method.

●In consideration of the device life, make sure that the area around the equipment is well

ventilated. Select a place that is free of dust, corrosive or explosive gas, salt, moisture, steam,

and dew condensation, and where the product protected from wind and rain or direct sunlight.

A poor environment could degrade motor or control panel's insulation, etc., and can cause

earth leakages, electric shocks or fires.

●Do not use in an explosive atmosphere. There is a risk of fires.