kawneer.com

Laws and building and safety codes governing the design and use of glazed

entrance, window, and curtain wall products vary widely. Kawneer does not control

the selection of product configurations, operating hardware, or glazing materials,

and assumes no responsibility therefor.

Kawneer reserves the right to change configuration without prior notice when deemed

necessary for product improvement.

© Kawneer Company, Inc., 2011

2

(PART NO. 038-371) EC 97904-38

NOVEMBER, 2011

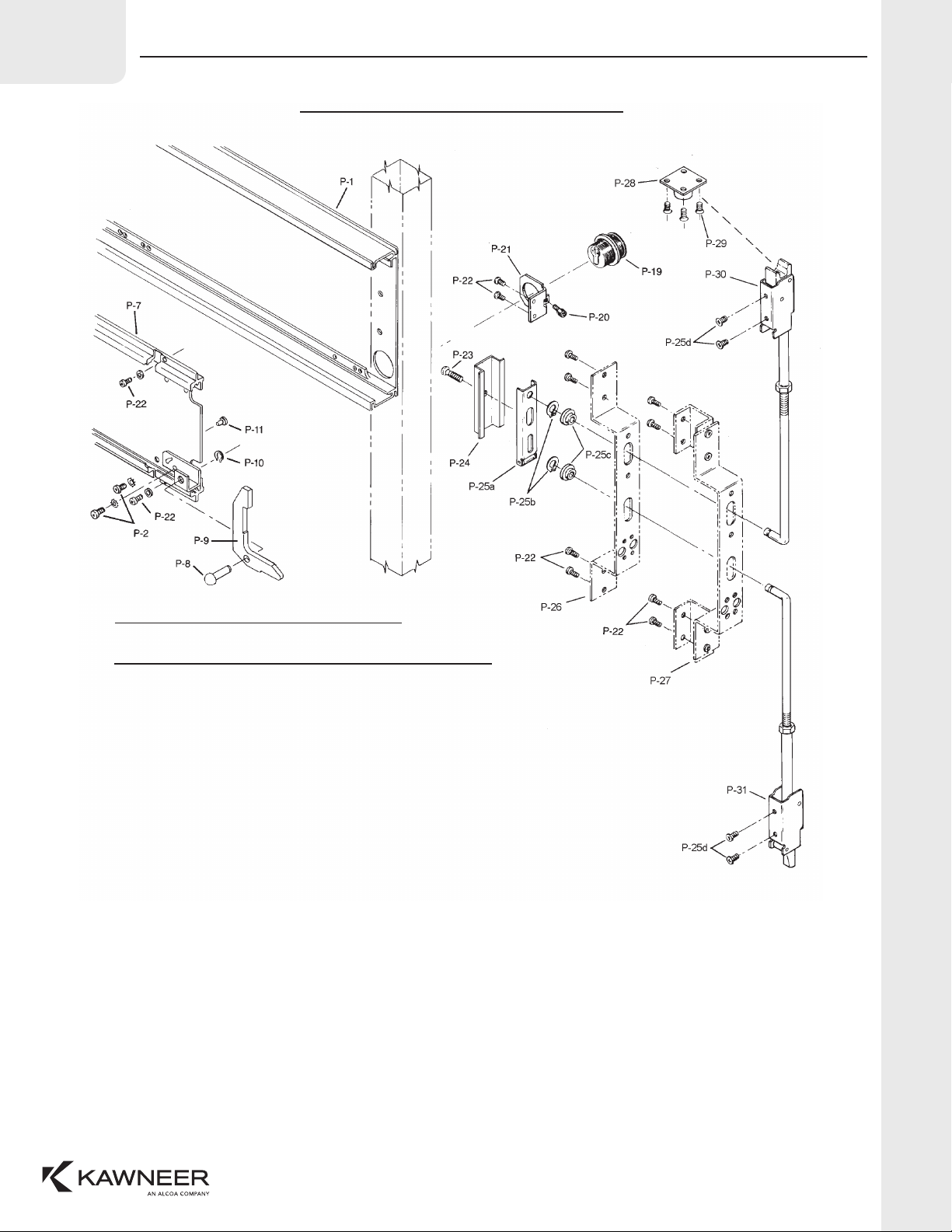

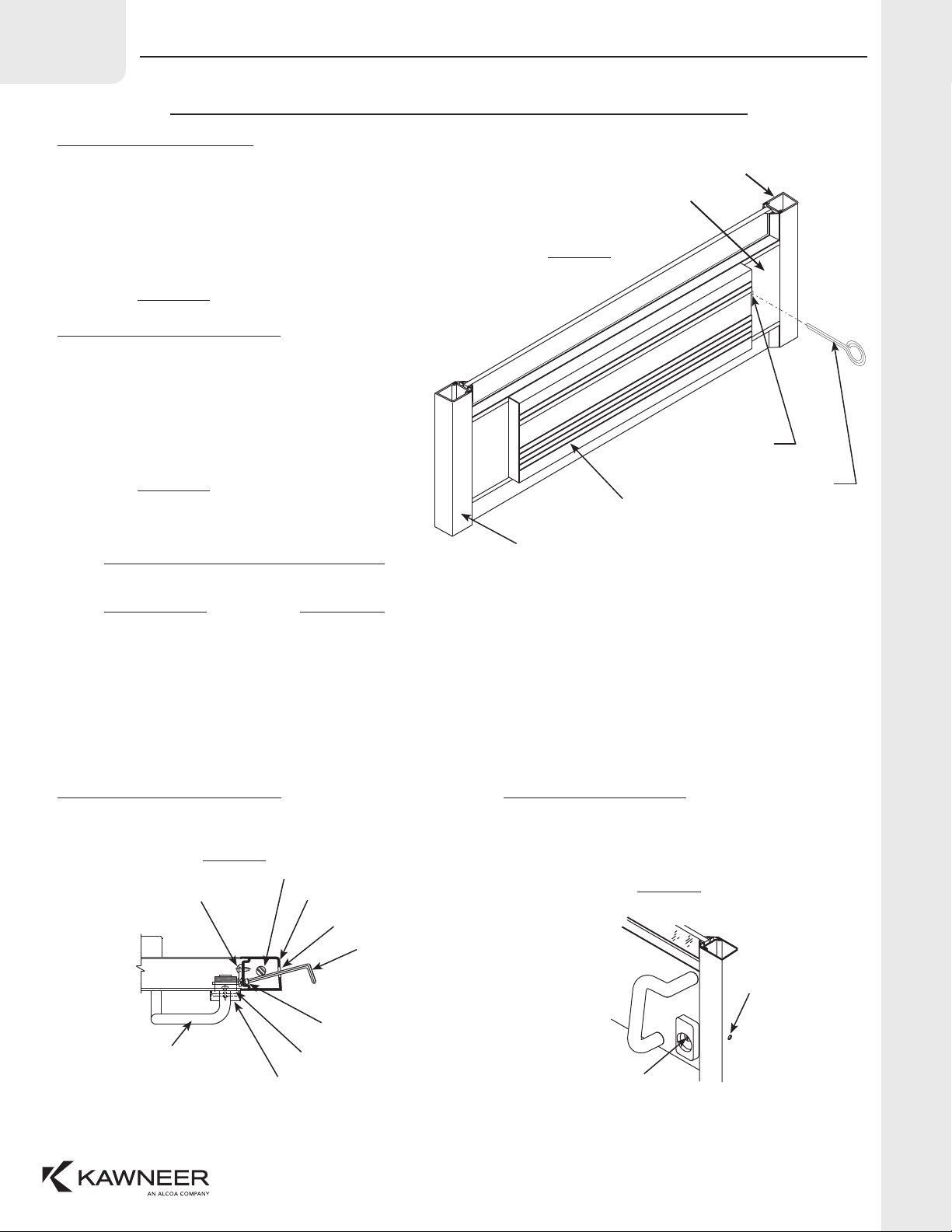

PANELINE®EXIT DEVICE

SERVICE INSTRUCTIONS

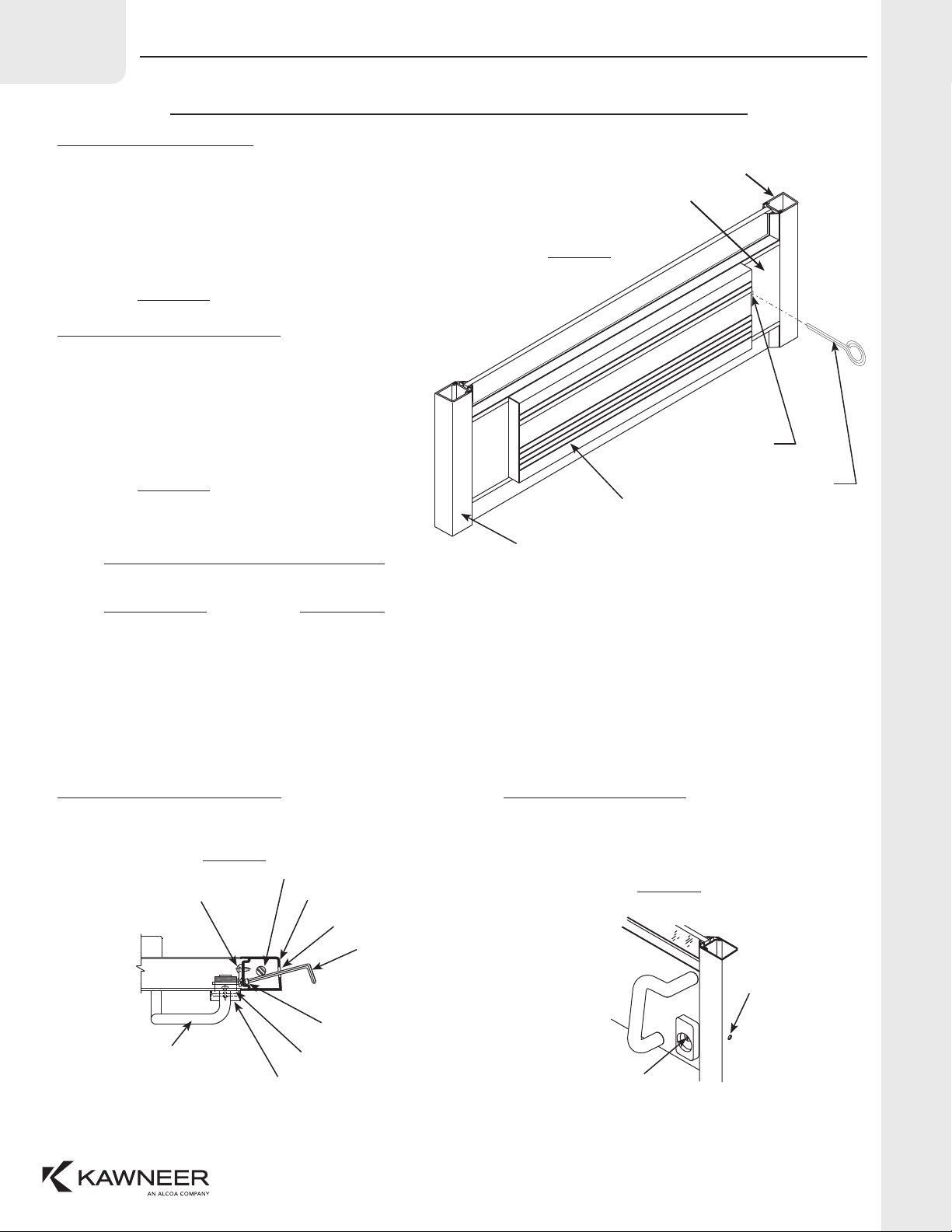

DOGGING INSTRUCTIONS AND LOCK CYLINDER INSTALLATION

DOGGING INSTRUCTIONS

To secure the exit device in the unlocked (dogged) position,

follow this sequence:

1. Fully depress push panel.

2. Insert dogging hex key (provided) into the access hole

in the middle of the filler plate closest to the hinge stile.

(See Figure A)

3. Turn key one-quarter turn clockwise.

Figure A

LOCK STILE

PUSH PANEL

DOGGING SCREW

LOCATION

HINGE STILE

FILLER PLATE

7/32" HEX KEY

INSTALLING CYLINDERS BY OTHERS

THE FOLLOWING CYLINDER BRANDS MAY BE USED WITH KAWNEER’S PANELINE®CR90 EXIT DEVICE:

MANUFACTURER CAM NUMBER

ELKEM-VING 9001

SCOVILL (YALE) 1161

UNICAN (ILCO) 15-L4002-64

SUPERIOR A

SARGENT 13-0097

BEST IEC4

SCHLAGE B502-191

CORBIN / RUSSWIN A62

NOTE: CYLINDER MUST HAVE 0.950 CAM SWEEP. IF CAM SWEEP IS LONGER IT MUST BE FILED DOWN.

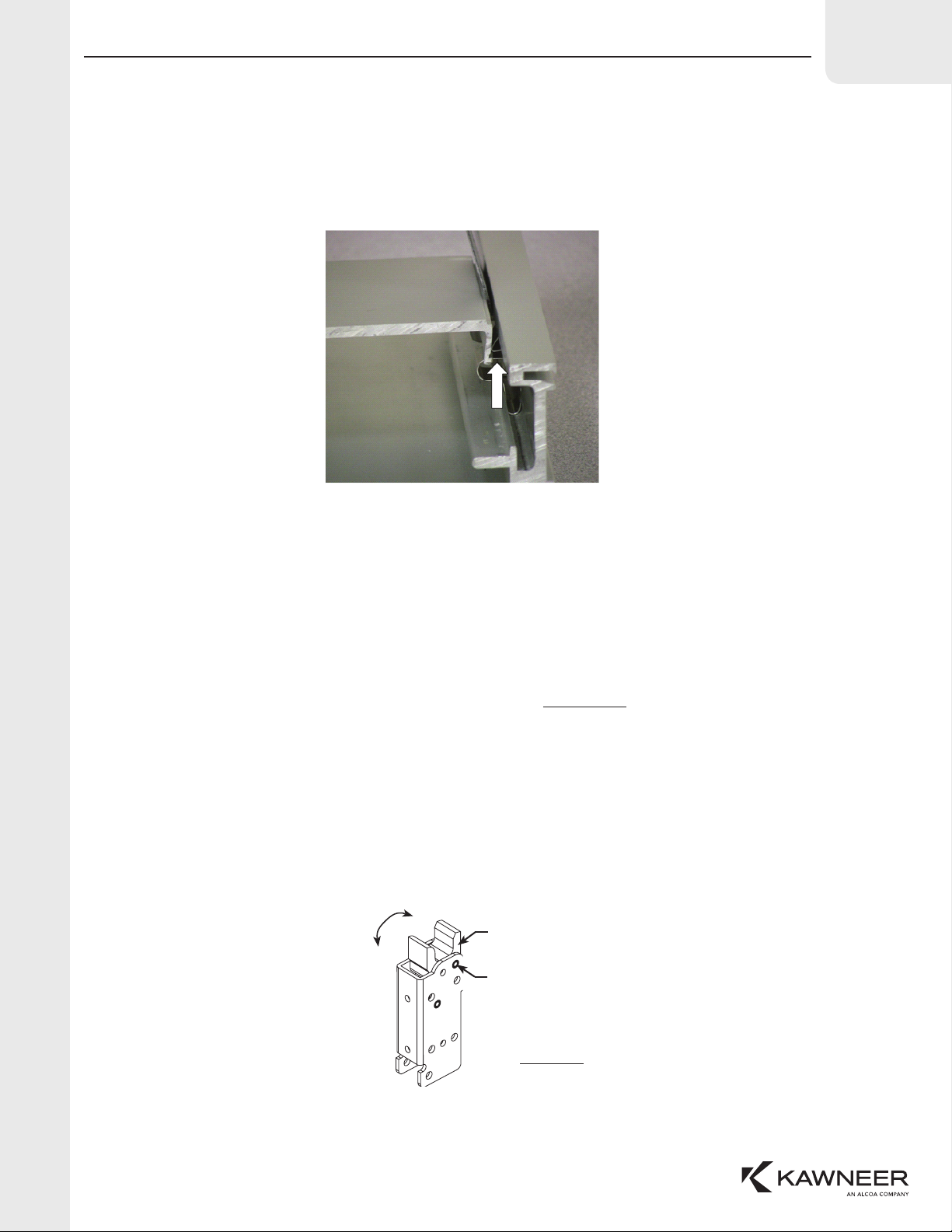

TO REMOVE LOCK CYLINDER

1. Open door and insert 9/64” allen wrench through hole in edge

of door stile at an angle that will engage the cylinder set screw.

Figure B

2. Loosen set screw about three full turns. Insert key part way

into cylinder key-way and turn to the left to remove lock cylinder.

EXIT DEVICE ROD

DOOR STILE

ACCESS HOLE

9/64" ALLEN WRENCH

CYLINDER SET SCREW

LOCK CYLINDER

OPTIONAL CYLINDER GUARD

DOOR PULL

CYLINDER BRACKET

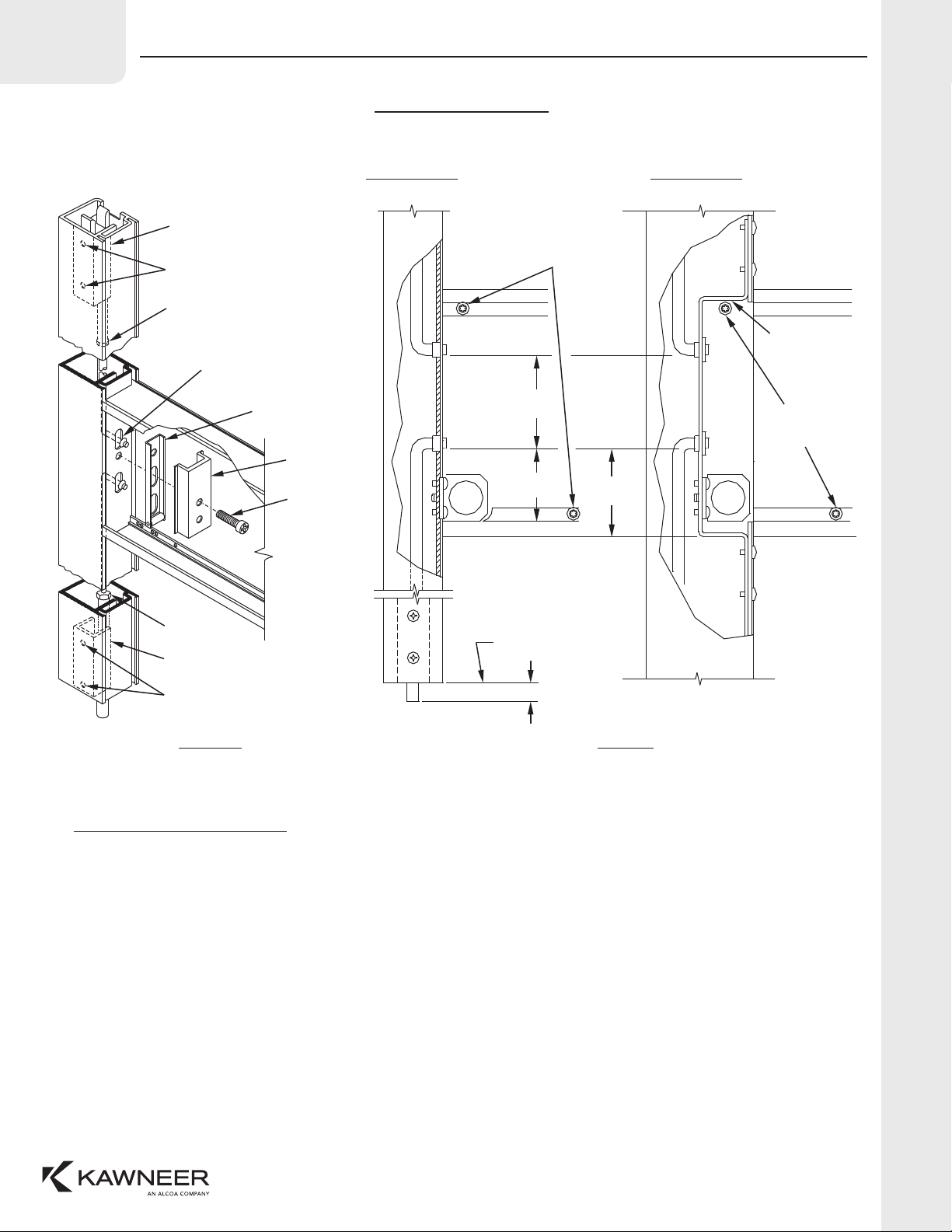

TO REPLACE CYLINDER

3. Install replacement cylinder with key-way up.

NOTE: Length and tip contour of new cylinder cam must

match old cylinder cam. Old cam may be used if necessary.

4. Tighten cylinder set screw and check unlocking action

with key.

SET SCREW

ACCESS HOLE

KEY-WAY UP

Figure C

UN-DOGGING INSTRUCTIONS

To return the exit device to the normal operation,

follow this sequence:

1. Fully depress push panel.

2. Insert dogging hex key (provided) into the access hole

in the middle of the filler plate closest to the hinge stile.

(See Figure A)

3. Turn key one-quarter turn counterclockwise.

4. Release panel.