Table of Contents

01.09.2011 Rev. 01 COMBISTOP Type 38 Page I

Table of Contents

1Introduction ...................................................................................................................1

1.1 Means of Representation.................................................................................................2

1.2 Safety Instructions...........................................................................................................2

1.2.1 General Safety Instructions .............................................................................................3

1.2.2 Safety Instructions for Operation .....................................................................................4

1.2.3 Safety Instructions for Maintenance.................................................................................4

1.2.4 Permissible Friction Work ................................................................................................4

1.2.5 Special Risks when Using the Brake ...............................................................................4

1.2.6 Risks Caused by Electric Power ......................................................................................5

1.2.7 Personal Protective Equipment .......................................................................................5

1.3 Obligation of the Operating Company..............................................................................5

1.4 Obligation of the Personnel .............................................................................................6

1.5 Specified Application .......................................................................................................6

1.6 Guarantee and Liability....................................................................................................7

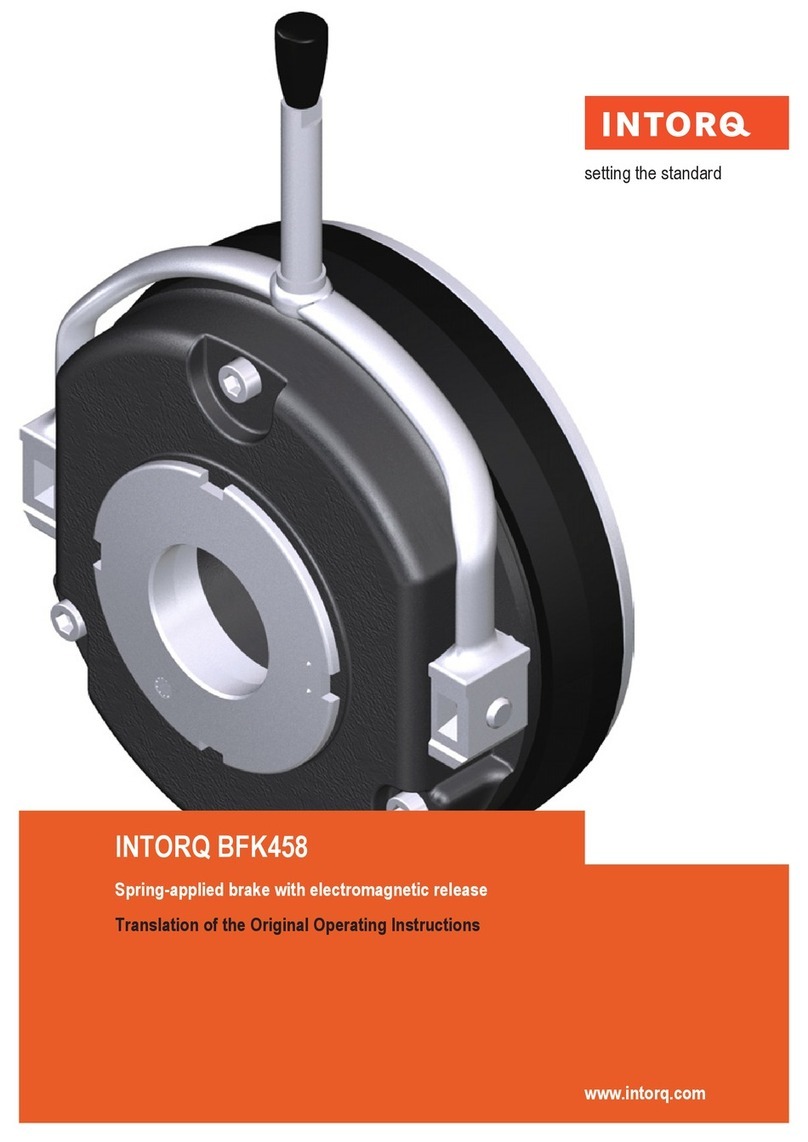

2Product Description ......................................................................................................8

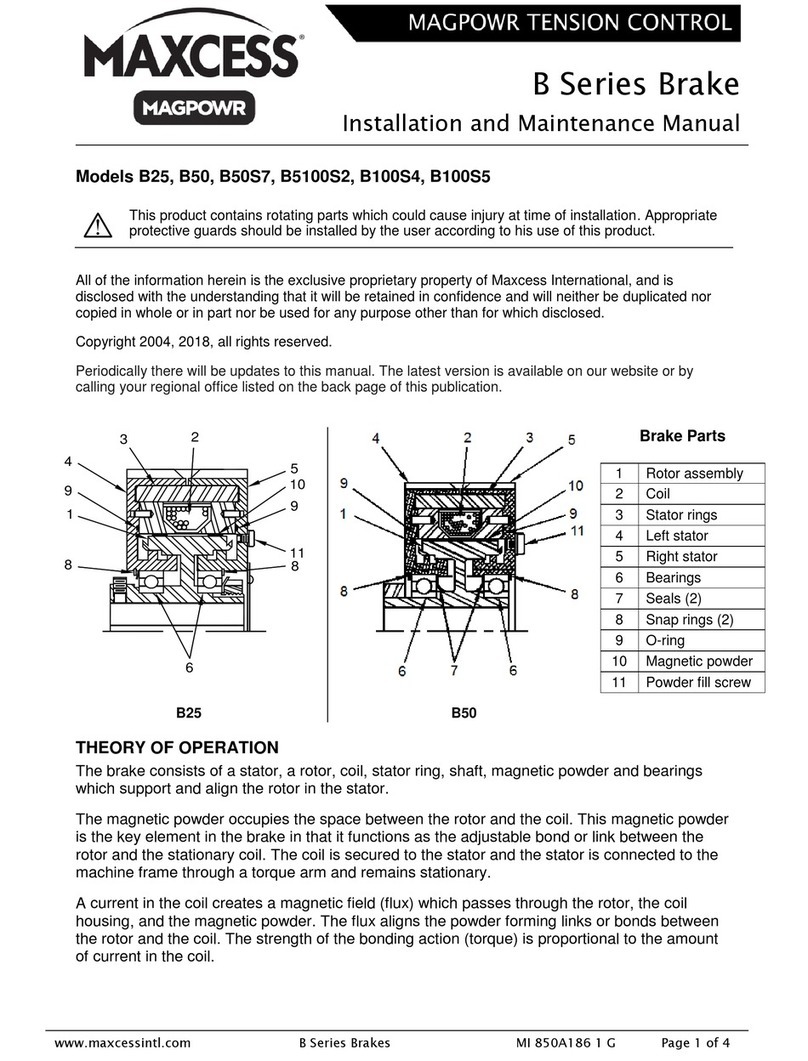

2.1 Overview/Parts List..........................................................................................................8

2.2 Functional Description .....................................................................................................9

2.3 Safety Devices ................................................................................................................9

2.3.1 Micro Switch (Option) ......................................................................................................9

3Transport and Storage ................................................................................................10

3.1 Inspections on Acceptance by the Recipient .................................................................10

3.2 Notes on Transport........................................................................................................10

3.3 Packaging .....................................................................................................................10

3.4 Storage Instructions for Temporary Storage ..................................................................10

4Mounting and Start-up ................................................................................................11

4.1 Mounting .......................................................................................................................11

4.1.1 Notes on Mounting ........................................................................................................11

4.1.2 Mounting the Brake .......................................................................................................12

4.1.3 Mounting the Hand Release (Option) ............................................................................14

4.1.4 Micro Switch (Option) ....................................................................................................17

4.1.4.1 Replacing the Micro Switch ...........................................................................................18

4.1.4.2 Checking the Micro Switch Settings...............................................................................19

4.1.4.3 Readjusting the Micro Switch ........................................................................................20

4.1.5 Electrical Connection.....................................................................................................21

4.1.5.1 Connecting the Brake ....................................................................................................22

4.2 Initial Start-up ................................................................................................................24

4.2.1 Inspections prior to Start-up of Brake ............................................................................24

4.2.2 Notes on Running-in Process ........................................................................................24

5Operation .....................................................................................................................25

5.1 Actuating the Hand Release ..........................................................................................25

6Malfunctions ................................................................................................................26