7

between 1 - 1.2m long. The hose should not be subjected to abrasion, kinking or permanent deformation and

should be able to be inspected along its entire length. Unions compatible with the hose fittings must be used

and connections tested for gas leaks.

.The fixed consumer piping outlet should be at approximately the same

height as the cooker connection point, pointing downwards and approximately 150mm to the side of the

cooker. The hose should be clear of the floor when the cooker is in the installed position. Fix one end of the

chain on the screw next to the gas inlet connection and the other end should be anchored to the floor/wall so

that the chain prevents strain on the hose connections when he cooker is pulled forward.

The appliance is factory set for Natural gas. The test point pressure should be adjusted to with the

Wok burner operating at maximum.

The appliance is set up to operate with the gas specified on the gas type label placed on the back of the

appliance.

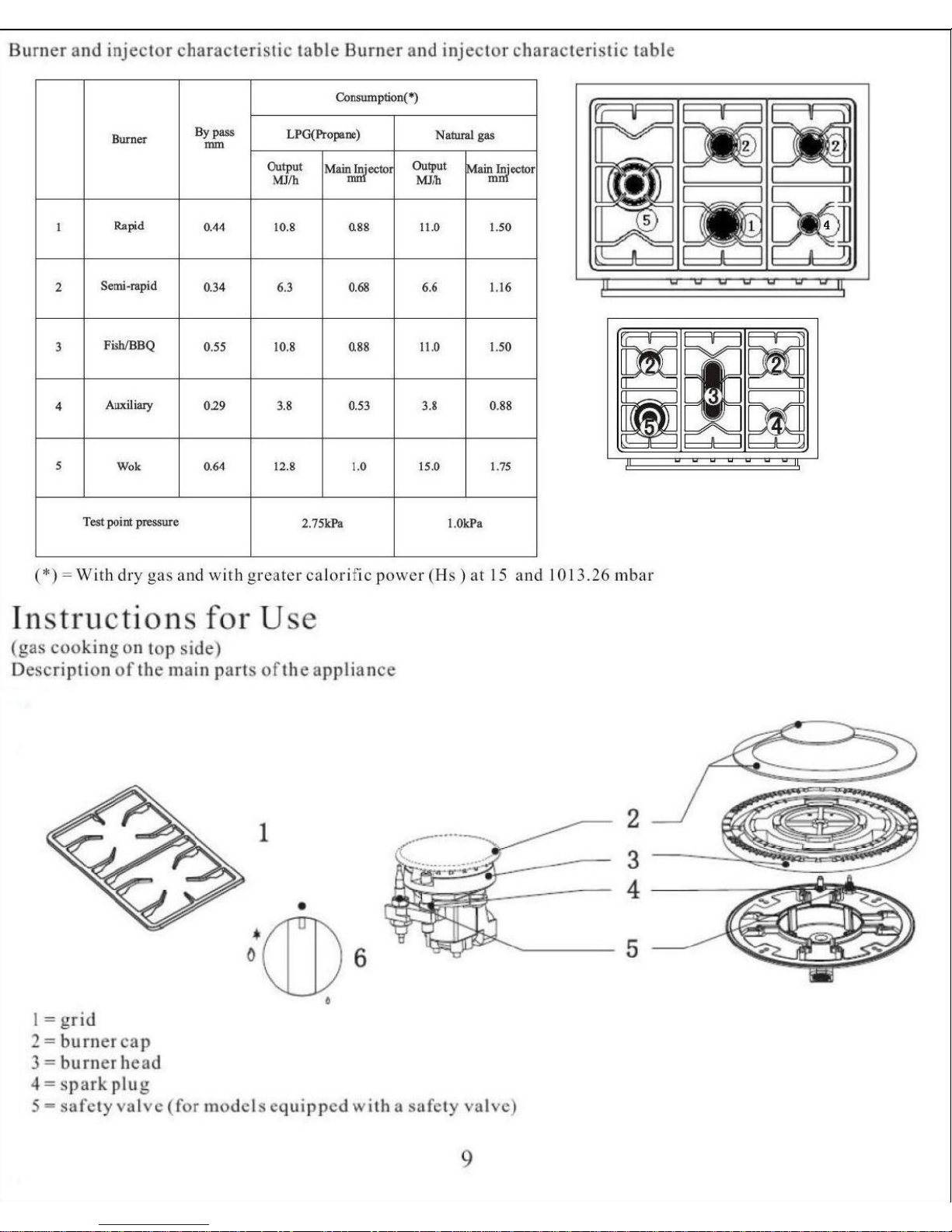

To perform these operations the qualified installer will follow the indications given in the "Adaptation to the

various types of gas" section. For safer operation make sure that the supply pressure respects the values given

in the "Table of burner and injector characteristics".

If installing for use with gas, ensure a gas regulator suitable for a supply pressure of is part of the

gas tank supply and the test point pressure is adjusted to .

Once the appliance has been installed, make sure that the gas pipe is neither squashed or damaged by moving

parts.

Before Leaving - Check all connections for gas leaks with soap and water. DO NOT use a naked flame for

detecting leaks. Ignite all burners both individually and separately to ensure correct operation of gas valves,

burners and ignition. Turn gas taps to low flame position and observe stability of the flame for each burner

individually and separately. When satisfied with the operation of the cooker, please instruct the user on the

correct method of operation. In case the appliance fails to operate correctly after all checks have been carried

out, refer to the authorised service provider in your area.

Adaptation to different types of gas

To adapt the appliance to a gas different from that

for which it was set up (see gas type label inside

the warming compartment door) proceed as follows:

remove the grids

remove the burners caps and burner heads

with a 7 mm socket spanner unscrew and remove the injectors.

replace the injectors with those supplied corresponding to the

gas available (see burner and injector characteristics Table)

replace the various parts proceeding in reverse.

When converting from Natural Gas to ensure that theNG regulator is removed and replaced with the Test

Point Assembly. A gas regulator suitable for a supply pressure of should be part of the gas tank supply and the

test point pressure should be adjusted to

Setting the minimum flame

The flame on the small output is regulated by the factory.

When the injectors have been replaced or there are special

mains pressure conditions, it may be necessary to regulate

the minimum flame again. The operations necessary to set

the minimum flame are as following:

light the burner ;

turn the knob to the minimum position ;

take out the knob (and gasket if there is one) ;

The flexible tube shall be fitted in such a way that it cannot come into

contact with a moveable part of the housing unit (e.g. a drawer)and does not pass through any space

susceptible of becoming congested

20mbar

LPG 29mbar

29mbar

When converting from Universal LPG to Natural Gas ensure that the LPG test point is removed and replaced

with the CE Approved NG Regulator supplied in this kit. The test point pressure must be adjusted to

20mbar with the largest burner operating on maximum flame.

When converting from Natural Gas to Universal LPG ensure that the NG regulator is removed and replaced

with the Test Point Assembly supplied in this kit. An CE Approved gas regulator suitablefor a supply pressure

of 29mbar should be part of the gas tank supply and the test point pressure must be adjusted to 29mbar.

LPG

the pressure according to the data plate.

l

l

l

l

l

l

l

l