KENT USA JHC-18S User manual

www.kentusa.com I 1.800.KENUSA

Property of Kent Industrial USA

Do Not Reproduce

Operator

’

s Manual

MACHINE NAME

:

CENTERLESS GRINDING MACHINE

MODEL

:

□

JHC-12BN

□

JHC-12S

□

JHC-18

□

JHC-18A

□

JHC-18B

█

JHC-18S

□

JHC-18AS

□

JHC-18BS

□

JHC-20

□

JHC-20S

File NO

:JHC-CLGM-E001

Date

:

2015.12.25

Version

:

R00

Original Instructions

Property of Kent Industrial USA

Do Not Reproduce

CONTENTS

I

Contents

1. SAFETY TIPS ................................................................................1-1

1.1 Warning tips............................................................................................1-1

1.2 General safety tips ..................................................................................1-2

1.3 Machine safety tips.................................................................................1-3

1.4 Tips for electrical equipments ...............................................................1-4

1.5 The SAMPLE AND POSITION FOR THE WARNING SIGN .........1-5

2. MACHINE SPECIFICATION .....................................................2-1

2.1 JHC-12 series specification....................................................................2-1

2.2 JHC-18 series specification....................................................................2-3

2.3 JHC-20 series specification....................................................................2-5

2.4 Machanism and part list ........................................................................2-7

2.5 Parts function........................................................................................2-10

2.6 Standard accessories.............................................................................2-12

2.7 Optional accessories..............................................................................2-13

3. MACHINE LAYOUT ....................................................................3-1

3.1 Floor space...............................................................................................3-1

4. TRANSPORTATION & INSTALLATION.................................4-1

4.1 Lifting.......................................................................................................4-1

4.2 Transportation ........................................................................................4-2

4.2.1 Center-of-gravity position of forklift and machine........................................4-2

4.2.2 Position offorklift transportation...................................................................4-3

4.3 Foundation...............................................................................................4-4

Property of Kent Industrial USA

Do Not Reproduce

CONTENTS

II

4.4 Leveling....................................................................................................4-5

4.5 Clean ........................................................................................................4-6

5. MECHANISM AND ADJUSTMENT..........................................5-1

5.1 Balance of grinding wheel......................................................................5-1

5.2 Assemble and disassemble of grinding wheel ......................................5-2

5.2.1 Procedure.......................................................................................................5-2

5.2.2 Tips:...............................................................................................................5-8

5.3 Spindle correction...................................................................................5-9

5.4 Grinding wheel dressing.......................................................................5-10

5.5 Assemble and disassemble of dresser..................................................5-11

5.5.1 Procudure ....................................................................................................5-11

5.6 Intoduction of regulating wheel...........................................................5-15

5.7 Workrestand blade support.................................................................5-28

5.7.1 Workrest.......................................................................................................5-28

5.7.2 Blade............................................................................................................5-29

5.7.3 Ejection and adjustment workrest andblade................................................5-30

5.8 Adjustment of thrufeed guide plate....................................................5-31

6. OPERATION..................................................................................6-1

6.1 Operation key description......................................................................6-1

6.2 Machine switch off procedure .............................................................6-10

6.2.1 Operaton panel............................................................................................6-10

6.2.2 Auto griding operation panel.......................................................................6-11

6.2.3 Switch of proximal regulating wheel motor.................................................6-12

6.3 Machine switch off procedure .............................................................6-12

6.4 Cable connection and trial run............................................................6-13

6.5 Working lamp replacement .................................................................6-14

Property of Kent Industrial USA

Do Not Reproduce

CONTENTS

III

6.6 Regulating wheel servo motor parameter list....................................6-15

7. MAINTENANCE & REPAIR.......................................................7-1

7.1 Notes of maintenance & repair..............................................................7-1

7.2 Period.......................................................................................................7-2

7.3 Monthly check list...................................................................................7-3

7.4 Oil-based maintenance...........................................................................7-5

7.5 Lubrication system .................................................................................7-6

7.5.1 Lubricator......................................................................................................7-6

7.5.2 Lubrication parts (12S.18S.20Sseries) ..........................................................7-9

7.5.3 Lubrication parts (12BN.18.18A.18B.20 series) .........................................7-10

7.6 Hydraulic system ..................................................................................7-12

7.6.1 Hydraulic circuit..........................................................................................7-12

7.6.2 Hydraulic pressure adjustment....................................................................7-13

7.6.3 Flow adjustment...........................................................................................7-14

7.7 Coolant selection...................................................................................7-15

8. TROUBLE SHOOTING ...............................................................8-1

8.1 Common cause & remedy......................................................................8-1

9. GRINDING APPLICATION ........................................................9-1

9.1 Centerlessgrinding principle .................................................................9-1

9.2 Centerless grinding method...................................................................9-3

9.2.1 Thrufeed method............................................................................................9-3

9.2.2 Infeed method.................................................................................................9-4

9.2.3 Endfeed method..............................................................................................9-4

9.2.4 Tangential feed method..................................................................................9-4

9.3 Grinding method for different workpiece............................................9-5

9.3.1 Short circle workpiece ...................................................................................9-5

Property of Kent Industrial USA

Do Not Reproduce

CONTENTS

IV

9.3.2 Disc-plateworkpiece ......................................................................................9-5

9.3.3 Long bar workpiece .......................................................................................9-5

9.3.4 Attache-head workpiece.................................................................................9-6

9.3.5 Cross-shape workpiece..................................................................................9-6

9.3.6 Multi-size workpiece......................................................................................9-6

9.3.7 Cone workpiece..............................................................................................9-7

9.4 Introduction of grinding wheel..............................................................9-8

9.5 Grinding wheel circumferential speed................................................9-13

9.6 Grinding difficulty and solution..........................................................9-16

9.7 Spare parts.............................................................................................9-19

9.8 Size List of Grinding Wheel and Regulating Wheel..........................9-23

Property of Kent Industrial USA

Do Not Reproduce

1SAFETY TIPS

1-1

This operation manual is to decscribe how to install, operate the machine and a

basicmaintenance and inspection. This manual will teach you how to operate the

machine safely and correctly to make this machine work appropriately. Please read

this instruction manual carefully before installation and operation. This safety tips

and warning sign of manual are very important. Please fully understand before

operating machine.

1.1 Warning tips

To avoid serious injure, the owner and all operator should provide encesary protection

equipments for the regular operation and special operation. The owner should select

qualified person with proper grinding trainning to operate and maintain the machine.

Also, please follow below safety rules and local laborer safety laws.

1. This machine will be only operated by qualify operator who knows the

machine’s specification and safety rules very well.

2. When machine is running, don’t get close to any movable parts of machine.

If need, please turn off the machine power.

3. Pleare wear protective hair cap or hold hat to prevent long hair from failing

down during operation.

4. Do not wear relaxed clothing and gloves during operation. Long sleeves and

neckties must be buckled.

5. Please wear goggles and protecton mask to avoid damage by accident or

mis-operation. Wear safety shoes while operating this machine.

6. Do not operation this machine without any guidance and supervision.

1. SAFETY TIPS

Property of Kent Industrial USA

Do Not Reproduce

1SAFETY TIPS

1-2

7. Please stop the spindles when change / adjust the workpiece or equip /

dismantle the accessories.

8. Do not use inflammable or poisonous coolant.

9. Please stop the machine immediately when find out any safe problem and

ask for help from local agent.

10. Do not remove any warning sign from the machine.

1.2 General safety tips

To eliminate accident and keep the machine working well, the safety

considerations are very important. Pay attenton on the safety rules will much

increase the productivity.

1. Wear the goggles and mask.

2. Wear the safety shoes.

3. Wear the safety helmet and overall and tight the cuff.

4. Do not wear gloves while operating machine.

5. Keep the area where around machine clean, dry and bright anytime.

6. Make sure machine foundation is rigid and steady, also keep floor tightened

around the operation area.

Property of Kent Industrial USA

Do Not Reproduce

1SAFETY TIPS

1-3

1.3 Machine safety tips

Before operating this machien, the operator must fully understand this manual.

1. The operator and service person must be pay attention to the warning sign.

Do not remove or damage.

2. All guard and doors should be secured all the time except maintenace to

prevent dirts entering controller.

3. Do not move limit switch to change the slide travel.

4. Use proper tools to adjust, maintain and repair machine.

5. Any problem occured, please stop the machine immdediately.

6. Before operation daily, pease aware of below tips.

1) When machine is running, do not close to any movement or rotation

aprts, such as grinding wheel and regulating wheel.

2) Do not use hand to clearn the chips which on the wheel and worktable.

Please clean after machine is stoped.

3) Stop teh machine while adjusting the direction of coolant spray.

4) Do not try to touch or change the workpiece when worktable moving or

workpiece is near ginding wheel.

5) Place workpiece between centers and make sure it’s tightened.

6) Do not use objects to force machine stop.

7) Stop the machine immediately when unusual situation happened during

the machine is running. Restart the machine after problems are solved.

8) Make sure the work space is enough for the running stroke of machine

worktable. Keep irrelative staff away from the machine.

7. Standard operation process for daily machine turn off.

9) Turn off the power.

Property of Kent Industrial USA

Do Not Reproduce

1SAFETY TIPS

1-4

10) Clean worktable.

11) Apply lubricator on sliders and cover to prevent dust.

1.4 Tips for electrical equipments

Please notice below tips before maintainance and inspection.

1. Do not hit controller and pressure control board.

2. Please use appointed wires specification which listed on manual. Wires

length shouldn’t be to long. If wires drag on floor, it must be covered up.

3. Do not change pressure control board or any other buttons without authority.

4. Do not over load the socket and connector.

5. Turn off main power before changing thefuse or any electrial parts.

6. Turn off NC controller, pressure control board and mainpower and lock at off

position while checking electrical equipment to avoid people turn on.

7. Do not use any wet tools to touch electrical equipment.

8. Please use proper and indicated fuse and never use high volume fuse or

cooper.

9. Open cabinet shortly to prevent sun light damage.

10. Check electrical circuit screws periodically especially higher current like

NFB, MS, Motors…etc., see if any loosen there to avoid mal-function or

shorted.

Property of Kent Industrial USA

Do Not Reproduce

1SAFETY TIPS

1-5

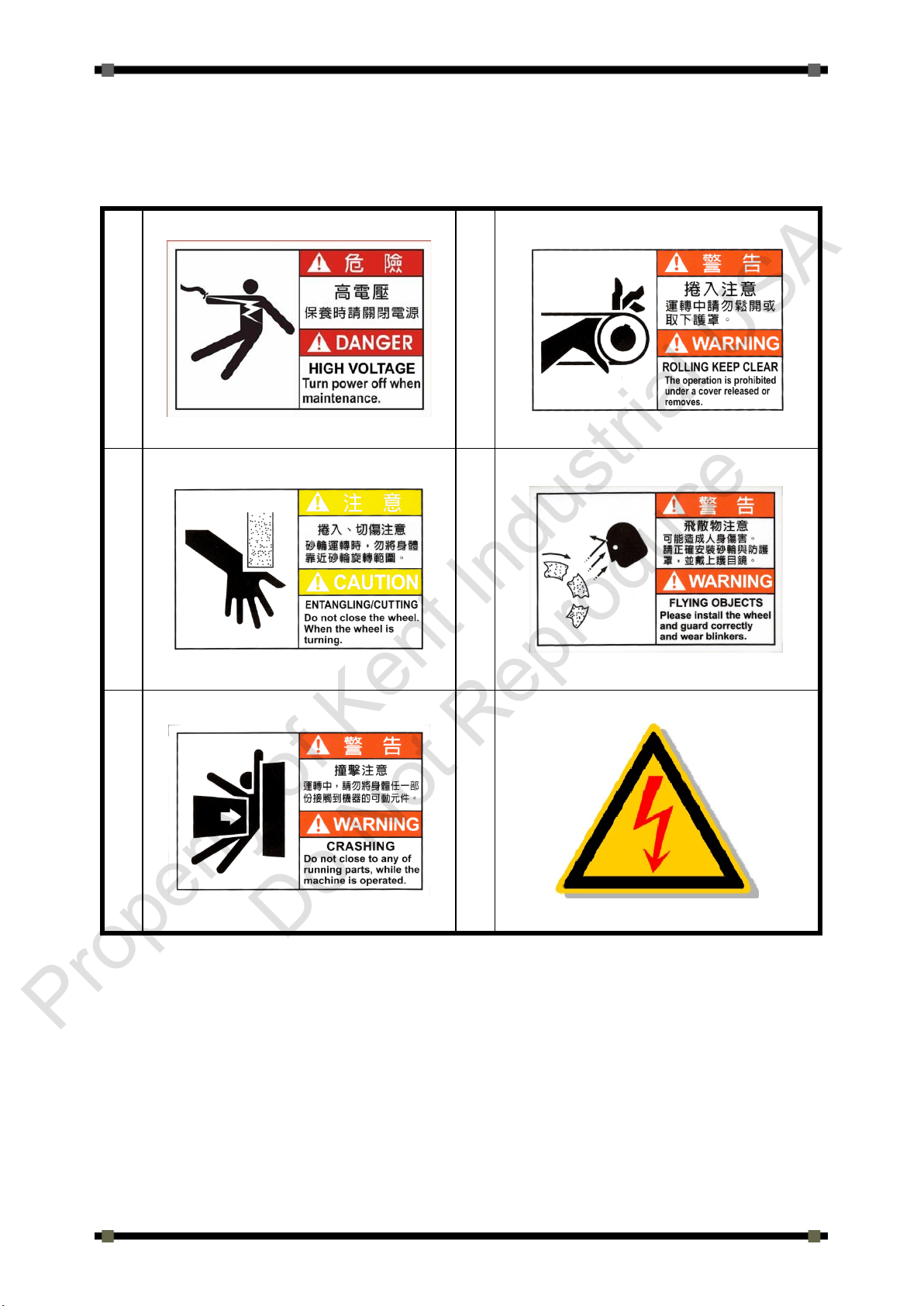

1.5The SAMPLE AND POSITION FOR THE WARNING

SIGN

1 2

3 4

5 6

Property of Kent Industrial USA

Do Not Reproduce

1SAFETY TIPS

1-6

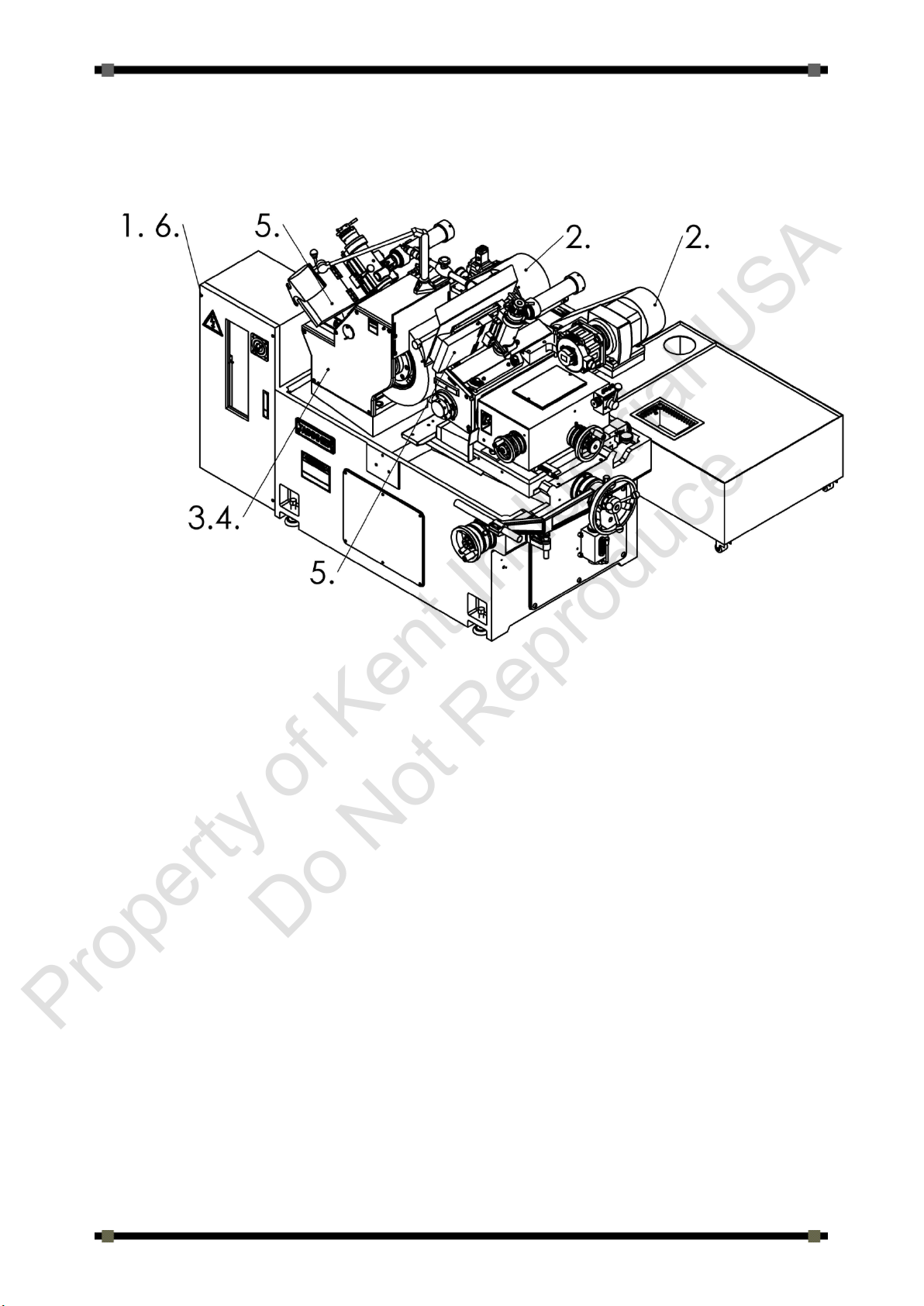

Warning Sign Location

Property of Kent Industrial USA

Do Not Reproduce

2 MACHINE SPECIFICATION

2-1

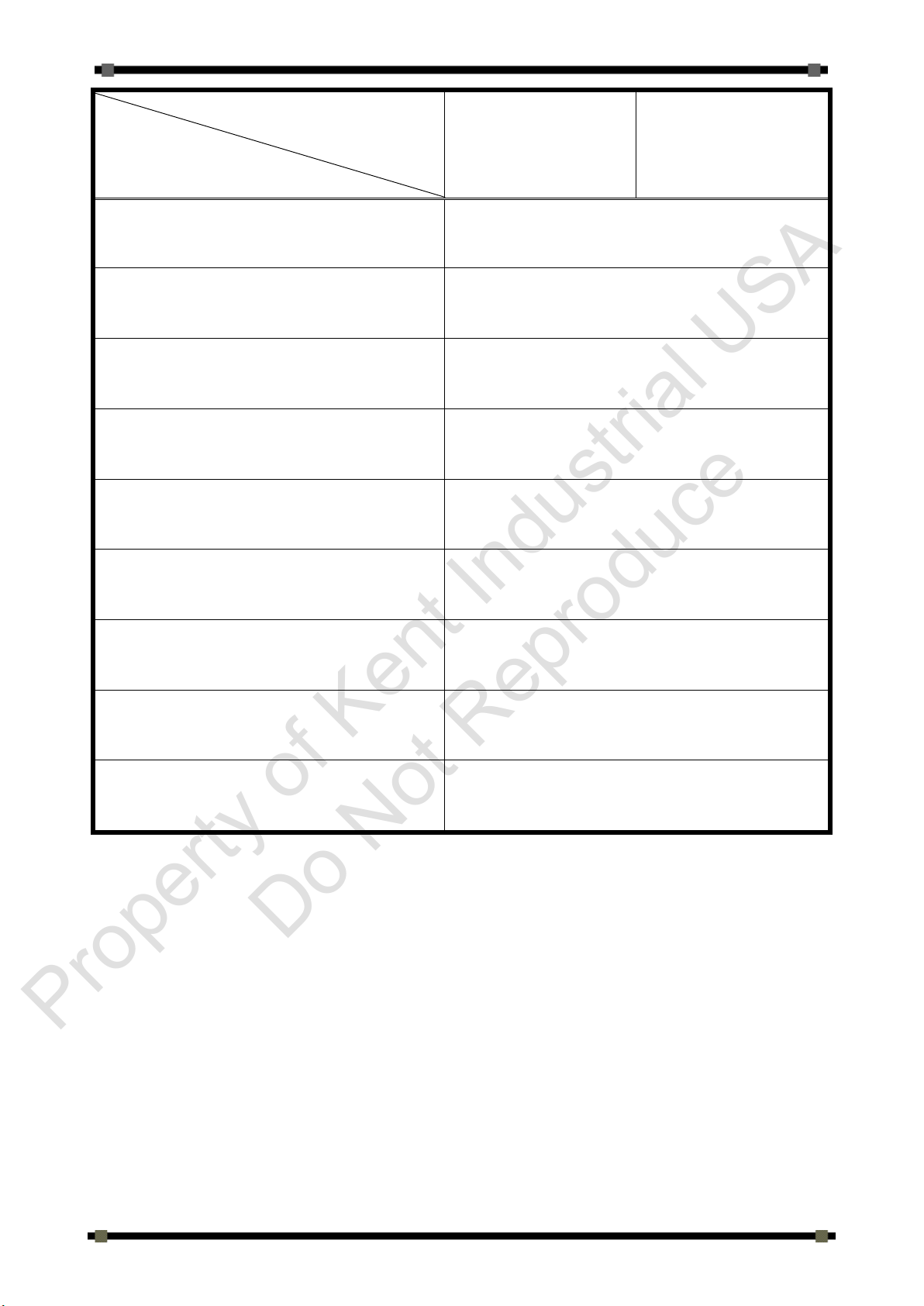

2.1 JHC-12 series specification

MODELS

ITEMS JHC-12BN JHC-12S

Std work rest(dia) ψ1~ψ25mm

Special work rest(dia) ψ25~ψ40mm

Grinding wheel size(dia×width×hole)

ψ305×150×ψ120

Regulating wheel size (dia×width×hole)

ψ205×150×ψ90

Grinding wheel speed 1900 R.P.M

Regulating wheel speed 20-

337 R.P.M

(7 step)

10-300 R.P.M

Stepless

Grinding wheel motor 7.5HP

Regulating wheel motor 1HP*6P 1.8KW

servo motor

Hydraulic pump motor 1HP

Coolant pump motor 1/8HP

Regulating wheel feed on handwheel

4mm(Rev)

0.02mm(Gra)

2. MACHINE SPECIFICATION

Property of Kent Industrial USA

Do Not Reproduce

2 MACHINE SPECIFICATION

2-2

MODELS

ITEMS

JHC-12BN JHC-12S

Table feed on handwheel 7mm(Rev)

0.05mm(Gra)

Table micro feed on handwheel 0.2mm(Rev)

0.001mm(Gra)

Dressing handwheel 1.25mm(Rev)

0.01mm(Gra)

Regulating wheel tilt angle +5°~-3°

Regulating wheel swivel angle ±5°

Machine size (L×W×H)( approx) 1800×1400×1400mm

Net weight (approx) 1600kgs

Shipping gross weight (approx)

1750kgs

Packing size(L×W×H) (approx) 2300×1100×1800mm

Property of Kent Industrial USA

Do Not Reproduce

2 MACHINE SPECIFICATION

2-3

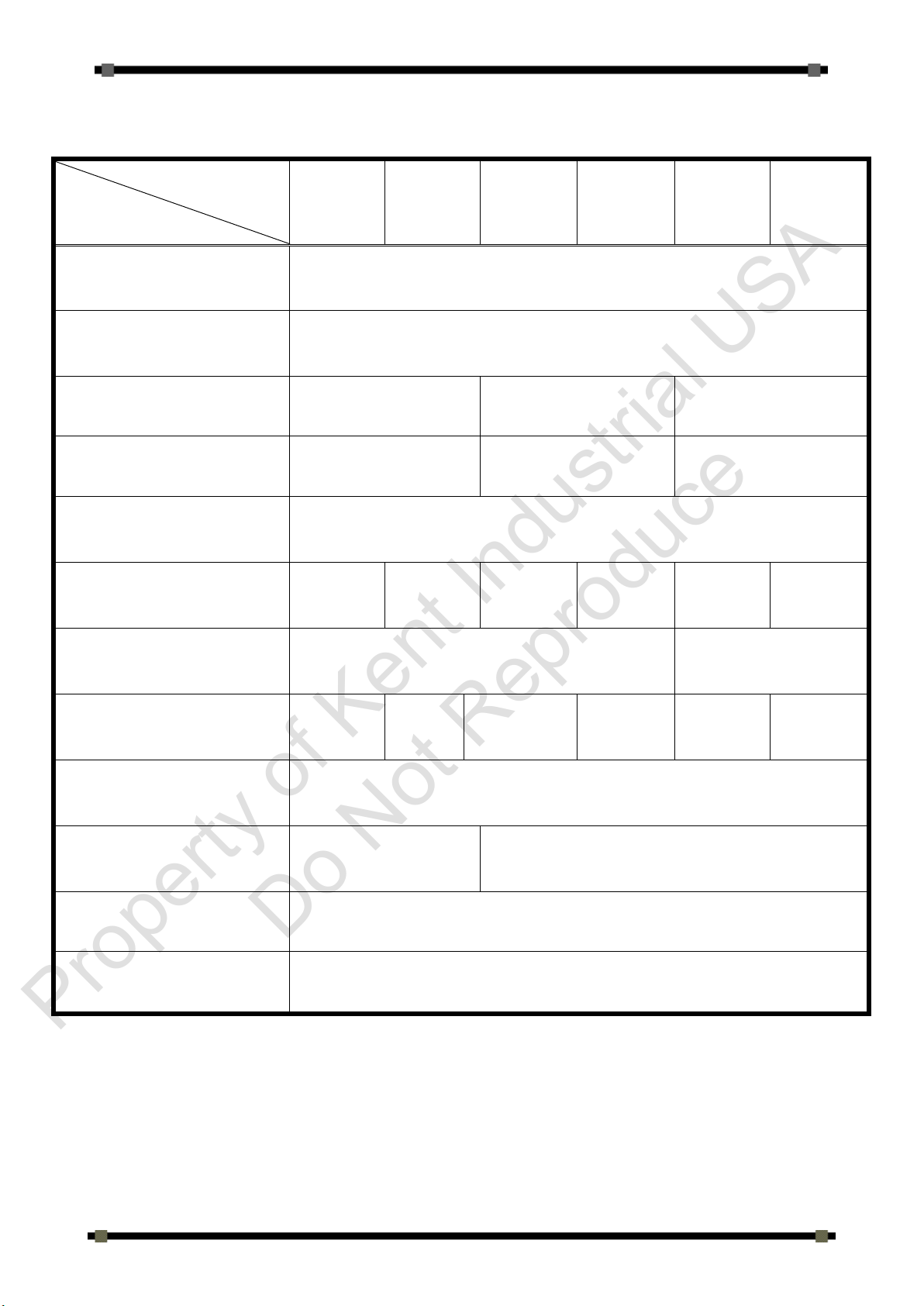

2.2 JHC-18 series specification

MODELS

ITEMS

JHC-18 JHC-18S JHC-18A JHC-18AS

JHC-18B JHC-18BS

Std work rest(dia)

ψ1~ψ50mm

Special work rest(dia)

ψ40~ψ100mm

Grinding wheel

size(dia×width×hole)

ψ455×205×ψ228.6 ψ455×255×ψ228.6 ψ455×305×ψ228.6

Regulating wheel size

(dia

×width×hole)

ψ255×205×ψ111.2 ψ255×255×ψ111.2 ψ255×305×111.2

Grinding wheel speed

1500 R.P.M

Regulating wheel speed

13-

316 R.P.M

(10 step)

10-

250 R.P.M

stepless

13-

316 R.P.M

(10 step)

10-250

R.P.Mstepless

13-

316 R.P.M

(10 step)

10-250

R.P.Mstepless

Grinding wheel motor

15HP 20HP

Regulating wheel motor

2HP*6P

2.9KW

servo motor 2HP*6P

2.9KW

servo motor 3HP*6P

4.4KW

servo motor

Hydraulic pump motor

1HP

Coolant pump motor

1/4HP 1/2HP

Regulating wheel feed on

handwheel

3.5mm(Rev)

0.05mm(Gra)

Regulating micro feed on

handwheel

0.1mm(Rev)

0.001mm(Gra)

Property of Kent Industrial USA

Do Not Reproduce

2 MACHINE SPECIFICATION

2-4

MODELS

ITEMS JHC-18 JHC-18S

JHC-18A JHC-18AS

JHC-18B

JHC-18BS

Table feed on handwheel 9mm(Rev)

0.05mm(Gra)

Table micro feed on handwheel 0.2mm(Rev)

0.001mm(Gra)

Dressing handwheel 2mm(Rev)

0.01mm(Gra)

Regulating wheel tilt angle +5°~-3°

Regulating wheel swivel angle ±5°

Machine size (L×W×H)approx) 2300×2000×1530mm

Net weight (approx) 2800kgs 2900kgs 3000kgs

Shipping gross weight (approx)

3100kgs 3200kgs 3300kgs

Packing size(L×W×H) (approx) 3200×1400×1900mm

Property of Kent Industrial USA

Do Not Reproduce

2 MACHINE SPECIFICATION

2-5

2.3 JHC-20 series specification

MODELS

ITEMS

JHC-20 JHC-20S

Std work rest(dia) ψ1~ψ50mm

Special work rest(dia) ψ40~ψ100mm

Grinding wheel size(dia×width×hole)

ψ510×205×ψ254

Regulating wheel size (dia×width×hole)

ψ305×205×ψ127

Grinding wheel speed 1350 R.P.M

Regulating wheel speed 13-

316 R.P.M

(10 step)

10-

250 R.P.M

stepless

Grinding wheel motor 20HP

Regulating wheel motor 3HP*6P 2.9KWservo motor

Hydraulic pump motor 1HP

Coolant pump motor 1/2HP

Regulating wheel feed on handwheel

3.5mm(Rev)

0.05mm(Gra)

Regulating micro feed on handwheel 0.1mm(Rev)

0.001mm(Gra)

Table feed on handwheel 9mm(Rev)

0.05mm(Gra)

Property of Kent Industrial USA

Do Not Reproduce

2 MACHINE SPECIFICATION

2-6

MODELS

ITEMS

JHC-20 JHC-20S

Table micro feed on handwheel 0.2mm(Rev)

0.001mm(Gra)

Dressing handwheel 2mm(Rev)

0.01mm(Gra)

Regulating wheel tilt angle +5°~-3°

Regulating wheel swivel angle ±5°

Machine size(L×W×H)(approx) 2300×2000×1530mm

Net weight (approx) 3200kgs

Shipping gross weight (approx)

3500kgs

Packingsize(L×W×H) (approx) 3200×1400×1900mm

Property of Kent Industrial USA

Do Not Reproduce

2 MACHINE SPECIFICATION

2-7

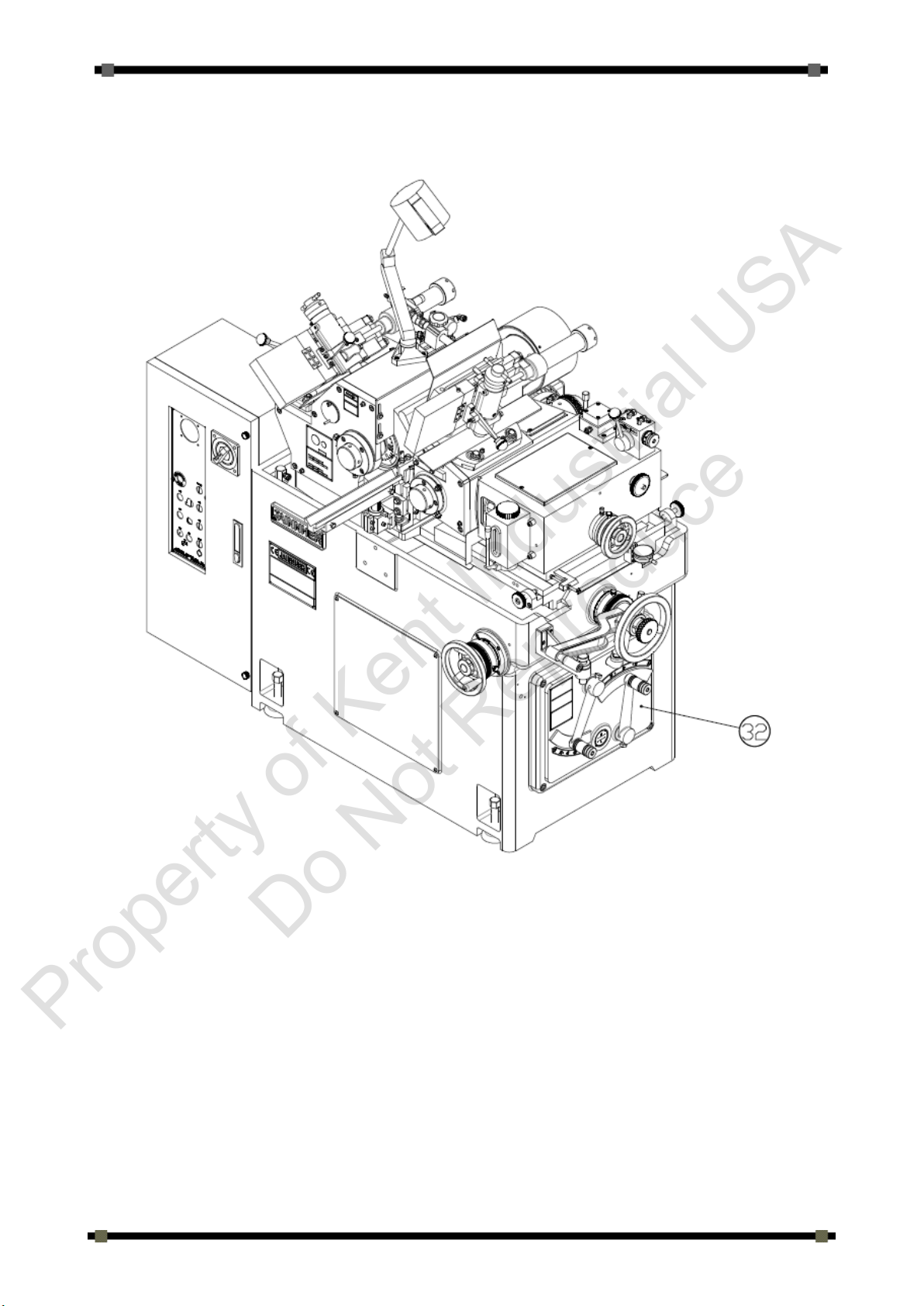

2.4 Machanism and part list

Property of Kent Industrial USA

Do Not Reproduce

2 MACHINE SPECIFICATION

2-8

NO. NAME NO. NAME

Property of Kent Industrial USA

Do Not Reproduce

Table of contents

Popular Grinder manuals by other brands

Central Pneumatic

Central Pneumatic 32046 Set up and operating instructions

BLACK DECKER

BLACK DECKER G915 Original instructions

Rayco

Rayco RG74T-R OPERATOR, SERVICE, MAINTENANCE MANUAL

Power Fist

Power Fist 8843534 manual

Max Pro

Max Pro MPAG760/125Q manual

VALERII S & M GROUP

VALERII S & M GROUP RTH122 Original instruction manual