5

fitting of the Die Grinder.

5. Always disconnect the Die Grinder from its compressed air supply

source, and squeeze the Trigger to release all compressed air in the

tool before performing any maintenance or services.

6. Industrial applications must follow OSHA requirements.

7. WARNING! Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities, contain chemicals known (to the

State of California) to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are: lead from lead-based

paints, crystalline silica from bricks and cement or other masonry products,

arsenic and chromium from chemically treated lumber. Your risk from

these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

8. WARNING! The warnings, precautions, and instructions discussed in

this manual cannot cover all possible conditions and situations that may

occur. The operator must understand that common sense and caution are

factors which cannot be built into this product, but must be supplied by the

operator.

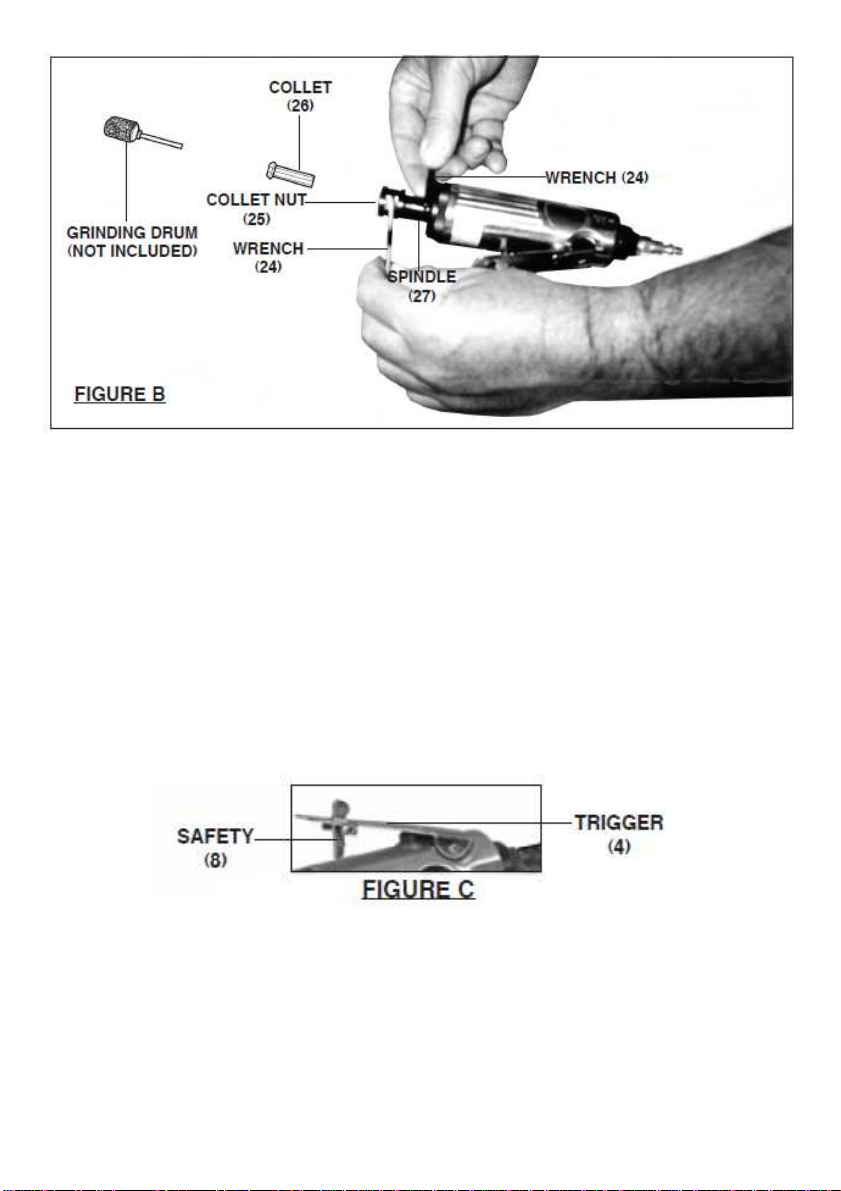

ASSEMBLY AND OPERATING INSTRUCTIONS

NOTE: For additional references to the parts listed in the following pages,

refer to the Assembly Diagram on page 9.

To Attach A Quick Connector:

1. WARNING! Prior to performing any assembly and/or adjustment

procedures, make sure the air supply hose (not included) is

disconnected from the Die Grinder.

2. Prior to use, the Die Grinder requires the attachment of a Quick

Connector into its Air Inlet. To do so, wrap approximately 3” of pipe

thread sealer tape (not included) around the male threads of a Quick

Connector. Then, firmly tighten the Quick Connector into the Air Inlet. (See

FigureA.)