KRC-356D/L/N

CONTENTS

/

CONNECTIONS

CONTENTS

PC

BOARD

(COMPONENT

SIDE

VIEW)

................

23

CONNECTIONS

os

sicssssovssessncccontdaceocctassstvacecsiieecesteies

2

PC

BOARD

(FOIL

SIDE

VIEW)

..............eeeeeeeeeeees

BLOCK

DIAGRAM

uuu...

ioc

ecceccseceseneeeeteeeneetereeatenee

3

SCHEMATIC

DIAGRAN

......00.....ce

cc

ceeeeeeeeereeeteene

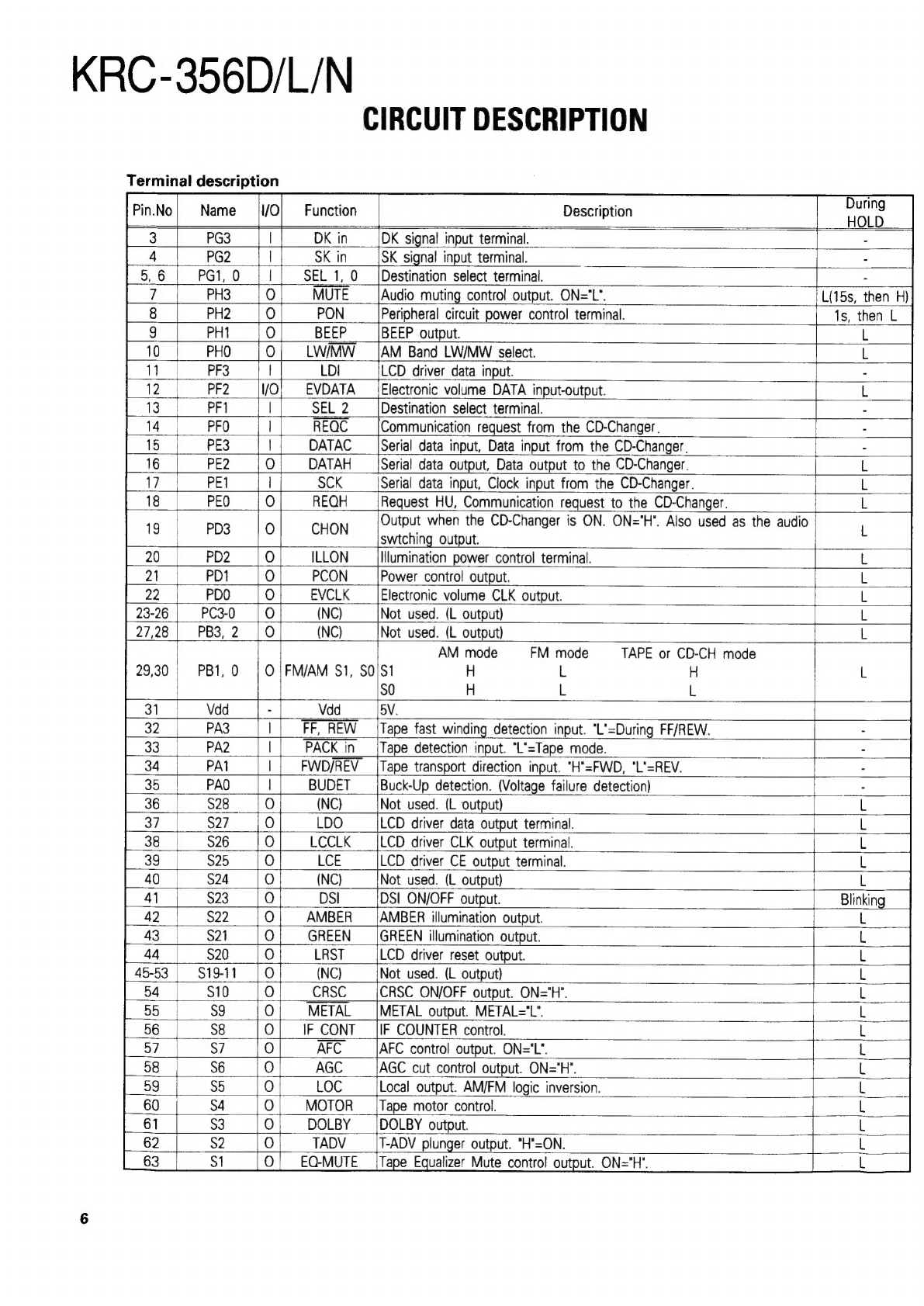

CIRCUIT

DESCRIPTION

.....0.0..

oe.

cece

eeeeseeteeeeee

il

EXPLODED

VIEW

(MECHANISM)

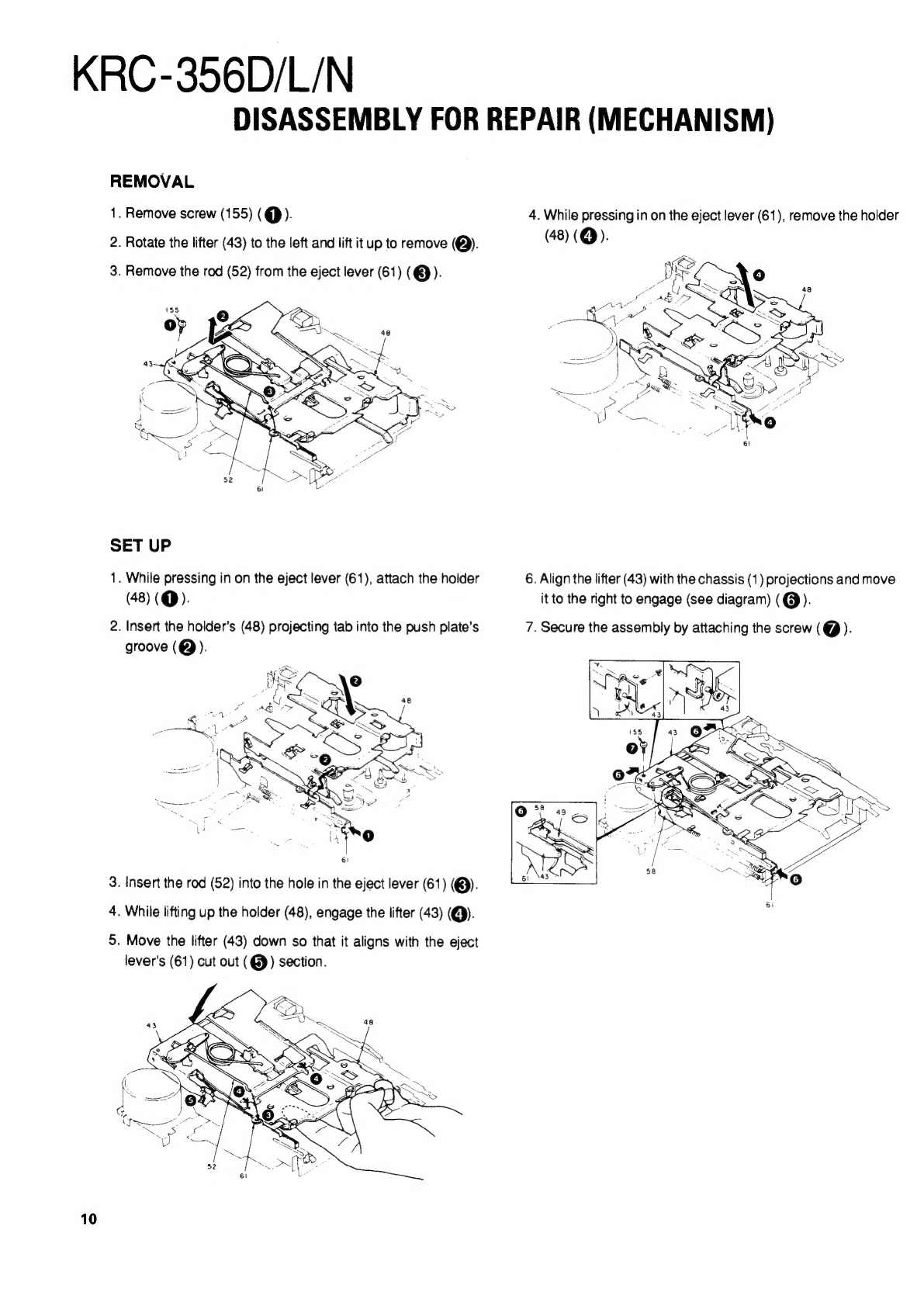

DISASSEMBLY

FOR

REPAIR

(MECHANIS®)

.......

10

EXPLODED

VIEW

(UINIT)

......

ccc

cceeceesseetrseenees

MECHANISM

OPERATION

DESCRIPTION

...........

11

PARTS

LIST

ociicscccasisienicicinnteesesseeuiisiade

casted

ADJUSTMENT

..........ccecccccsessscssssseecsseeeceeseeeeeneeens

20

SPECIFICATIONS

o.oo.

eee

eeeee

eens

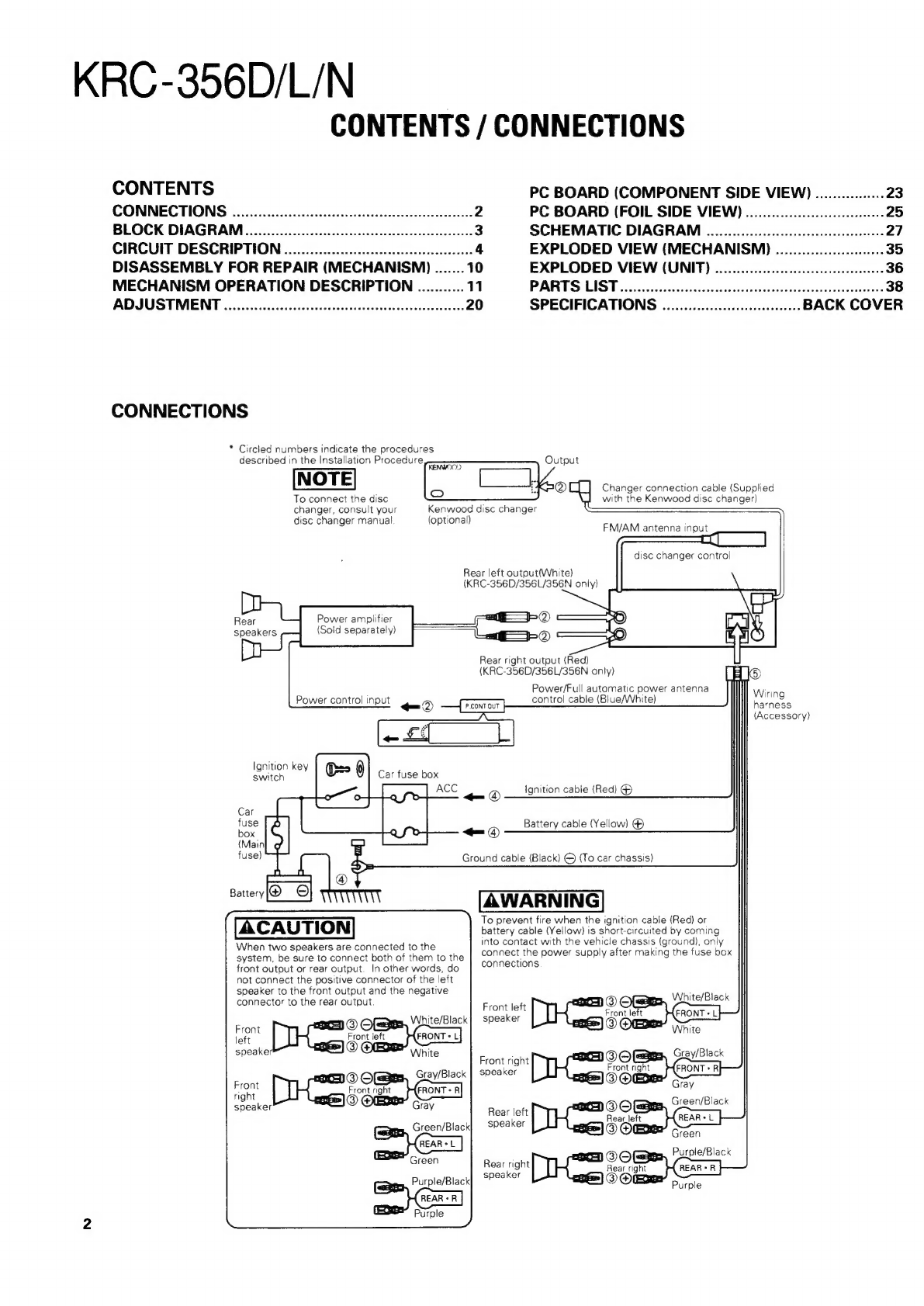

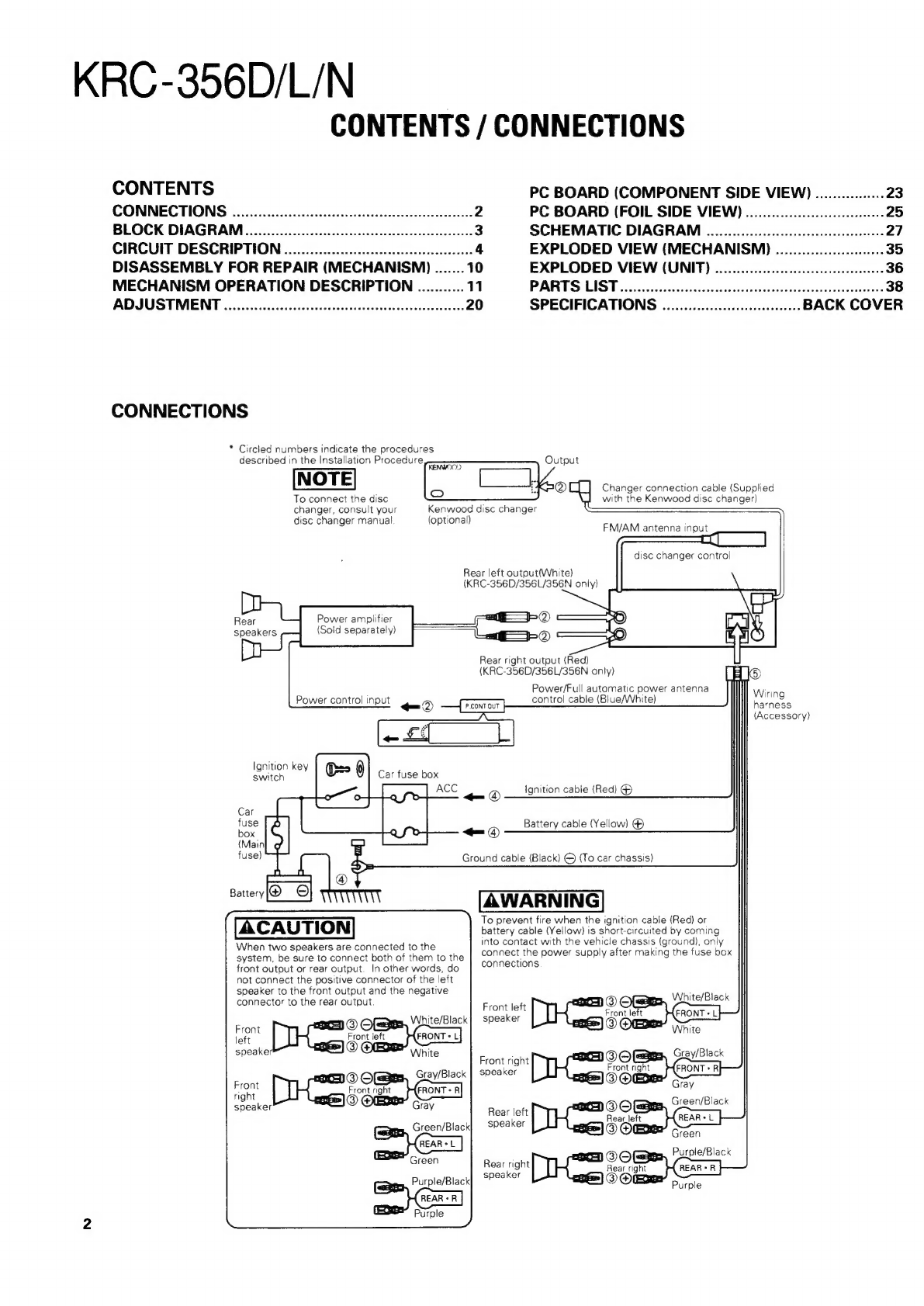

CONNECTIONS

*

Circled

numbers

indicate

the

procedures

described

in

the

Installation

Procedure

To

connect

the

disc

changer,

consult

your

disc

changer

manual!

(optional)

Rear

left

outout(White)

(KRC-356D/356L/356N

oniy)

Power

amplifier

(Soid

separately)

Rear

speakers

Power

control

input

-®

Ignition

key

switch

Battery

@

©

ACAUTION

When

two

speakers

are

connected

to

the

system,

be

sure

to

connect

both

of

them

to

the

front

output

or

rear

output.

In

other

words,

do

not

connect

the

positive

connector

of

the

left

speaker

to

the

front

output

and

the

negative

connector

to

the

rear

output.

Hes

@O@

ayes.

White/Black

Front

left

White

Gray/Black

Sra,

Kenwood

disc

change’

—-

©®

<—_©®

Output

Changer

connection

cable

(Supplied

with

the

Kenwood

disc

changer)

FM/AM

antenna

input

disc

changer

control

Rear

right

output

(Red)

(KRC-356D/356L/356N

only)

[H1é

Power/Full

a

nah

power

antenna

Wiring

contro!

cable

(Blue/White)

[

P.cont

ouT

}

harness

(Accessory)

Ignition

cable

(Red)

@

Battery

cable

(Yellow)

®

Ground

cable

(Black)

©

{To

car

chassis)

To

prevent

fire

when

the

ignition

cable

(Red)

or

battery

cable

(Yellow)

is

short-circuited

by

coming

into

contact

with

the

vehicle

chassis

(ground),

only

connect

the

power

supply

after

making

the

fuse

box

connections

sees

White/Black

Front

left

®

7

speaker

ront

left

SORE

White

-

seams,

Gray/Black

Front

right

Sols

y

speaker

O@Ee

~

Suen

Green/Black

Rear

left

20s

sa

(FERAL

]

speaker

@

Owen

os

lack

.

OCS

Purple/B

Rear

right

Rear

right

speaker

OLO)i=--

=

-

purple