KESD KZ-10A User manual

Ionizing air nozzle

KZ-10A

Operation Manual

Please read carefully before using it!

Read carefully before use

■Thanks for use our KZ-10A ionizer

■Read the manual before operation

■Please put the manual in a place where it can be seen at any time.

■Please use it according to the method recorded in the specification and operating

manual; otherwise, the company assumes no responsibility.

Please observe the following precautions for security

1, Connect compressed air first and then connect with power. It will cause inside

ozone increase if connect the power first, and this will inflect the device and

environment

2, Do not install the unit on a shock or thump device

3, Use clean air without oil and water

4, Do not use our product if the air contains these materials: organic solvent, organic

phosphate engine oil, sulphurous acid, chlorine and acid

5, Please do not use the emitter from other source. And do not reform it also.

Otherwise, it will cause breakdown, functional problems

6, The life of the emitter differs due to application environment and conditions. If the

application environment is critical (for example, environment with too high humidity)

or the spray point hasn’t been cleaned for a long time; its performance may be

declined. Therefore, must carry out maintenance regularly.

7, Make sure inside of the tube is clean before connect the compressed air, it will

cause block and abnormal running if the tube is mixed with cuttings and rust

8, The product is equipped with precision electronic components. Do not punch, drop

and impact onto the unit. It will cause damage outside of the surface, and probably

cause damage inside

Brief introduction

Stationary type static eliminator, light weight, small size, no static interference, safety

in operation, equip with HV normal and abnormal indicator light

Connect the compressed air before powering

Adopt pulse AC type, distribute positive and negative ions from the emitter needle by

compressed air, with superior performance in ion balance, can realize static eliminate

from point to big area. Various of nozzle heads for optional, suitable for different

applications

Characteristics

■Auto ion balance system, can achieve 0±10V

■Internal HV system, small size, safe and convenient

■Equip with normal running and HV abnormal alarm indicator light

■Can equip with different nozzle heads

■Tungsten alloy emitter for a long life time

■Metal sprayed internal wall, shield the hole device from grounding

■Various nozzle heads for different applications

Remark: Compressed air for functional, static elimination and dust remove,

compressed air range: 0.05-0.5 MPa

1, Use 0.1-0.3MPa for static elimination purpose

2, Use 0.3-0.5MPa for dust removal purpose

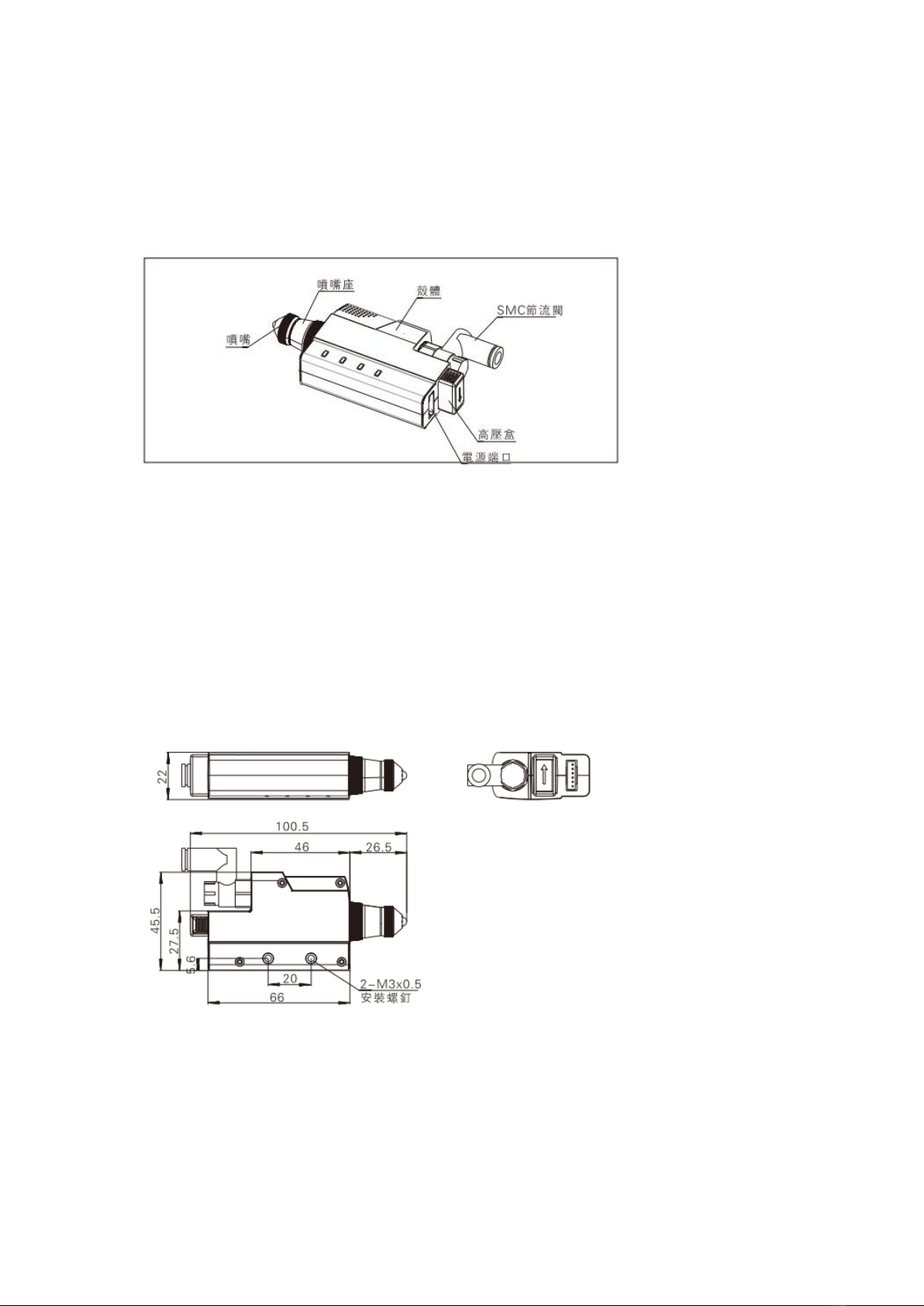

Structure Diagram

喷嘴 Nozzle head 喷嘴座 Nozzle base 壳体 Nozzle body SMC 节流阀 SMC

throttle valve 高压盒 HV box 电源端口 Power port

Breakdown drawing

1, HV box cover 2, Iron oxide circuit bard 3, Discharge needle assembly

4, HV box 5, Power port 6, Rubber mat

7, Right side of housing LED light 8, Discharge needle ring 9, Nozzle holder

10, Ceramic tube 11, Nozzle 12, Left side of housing

13, Inlet tube base 14, Throttle valve 15, Iron oxide

Dimension

Nozzle head optional:

Technical parameters

Model

KZ-10A

HV Output

2200V

Current

500mA

LED Indicator

Static elimination normal

LED Green light

Static elimination abnormal

LED Red light

Air applied

Air (clean air)

Air pressure range

0.05-0.5MPa

Applied environment

Temperature 0-40°C (No condensation)

Humidity 30-70% RH (No water drop condensation)

Ion generated type

High frequency AC type

Ion balance

0±10V

Ozone concentration

≤0.03ppm

Tube diameter

φ6mm

Dimension

104.5x56.5x22mm

Weight

0.09kg

Filter precision

0.01um

Filter efficiency

99.9%

Remark:

1, First connect the compressed air, and power connect after

2, Ion balance tested under our testing condition, contact for more

3, Filter is optional

Anti-static test condition

Operating voltage: DC24V Test voltage: ±1000V-±100V Amblent temperature: 23°C±2°C

Distance

150mm

300mm

Decay time

Positive

0.5s

0.8s

Negative

0.6s

0.9s

Ion balance

Positive

<0±10V

Negative

Remark: Static elimination performance (In accordance with ANSI ESD SP3.3-2006)

Power and signal wiring diagram

Maintenance

Open the nozzle head, take out ceramic tube, clean the tungsten emitter with alcohol

dipped cotton bud

After sale service

1, Warranty

One year warranty time for KESD products, repair and replace free for the problem

caused by the material and structure

2, Service after warranty

Repair service constantly for KESD products

Feedback from users

Operate in correct ways, follow the operation manual, thanks for your valuable

feedback on our products

Product Name

No

Production Date

Table of contents