Standard 40 mm fine pitch -X15

40

mm

+ Voltage

0

– Voltage

Frequency: High

Frequency: Low

Moving direction

Frequency: High

Moving direction

Frequency: Low

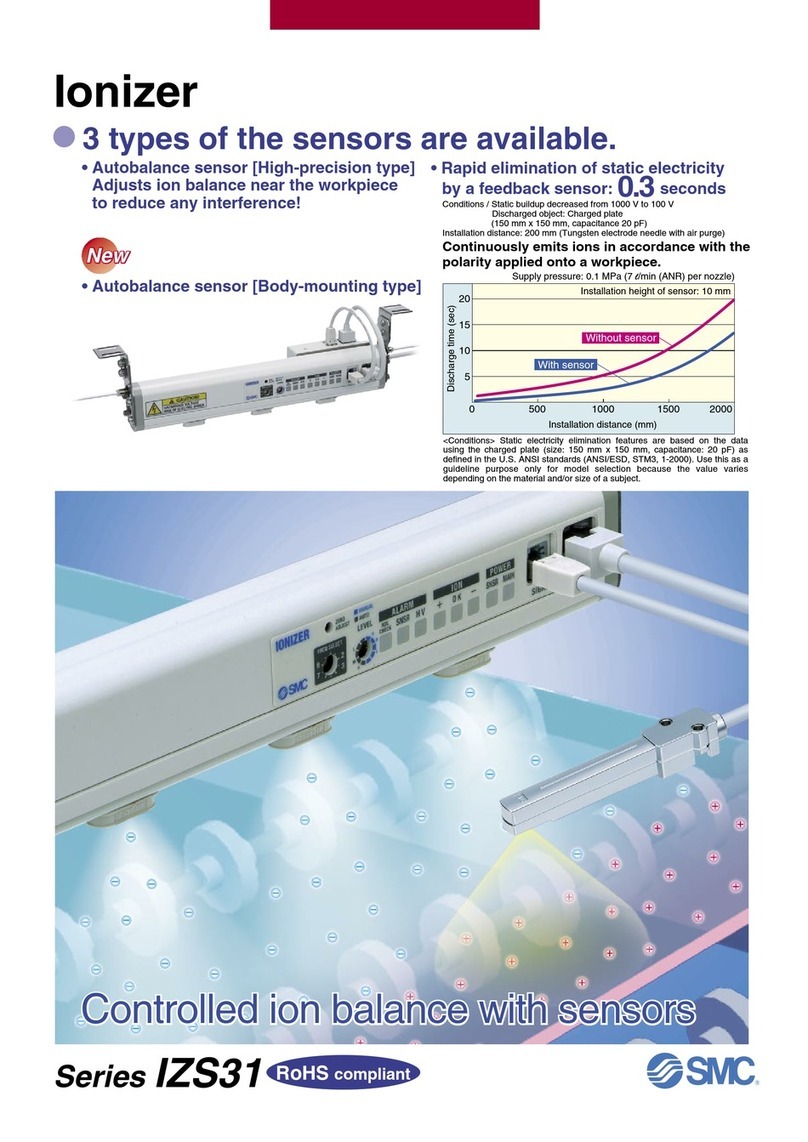

Installation distance (mm)

30

25

20

15

10

5

00 500 1000 1500 2000

Supply pressure: 0.05 MPa

(3.5 L/min (ANR) per nozzle)

Discharge time (s)

Supply pressure: 0.7 MPa

(30 L/min (ANR) per nozzle)

Air purge: Yes, With sensor: 1 Hz/60 Hz

Contamination of emitter

can be checked at the

same time.

Light ON: Within ±30 V

Flash: Around ±30 V

Light OFF and Alarm output:

Adjustment is not possible.

icity

r

PLC

+200 V

Charged object

Ionizer

Feedback sensor

Workpiece

electric polarity

LED

+ OK –

+400 V or higher

+100 V to +400 V

+30 V to +100 V

Within ±30 V

–30 V to –100 V

–100 V to –400 V

–400 V or lower

When attached

to the body

Positive

Static neutralization

completion

Negative

Workpiece electric

charge voltage

Applicable to workpiece moving

at high speed

•Switching over frequency: Max. 60 Hz

Ions are discharged at high density at

workpieces moving at high speed.

Effective static neutralization

for short distance

•

Prevention of irregular static neutralization

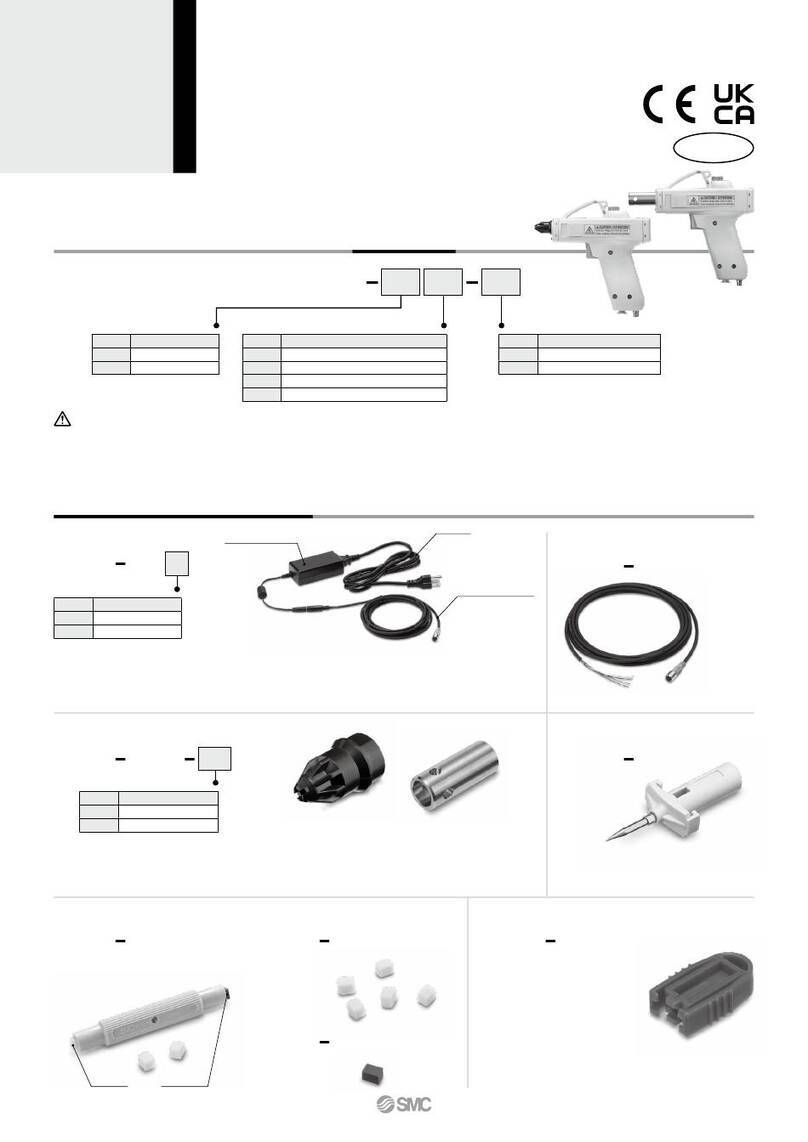

Emitter cartridge 40 mm-pitch:

-X15

(Standard: 80 mm-pitch)

(Length: 1260 mm or less)

Note) 80 mm-pitch in case

of air purge

Indicator functions

•Visualization of charging condition

(During sensing DC mode)

•Visualization of offset voltage

(When pulse DC mode or autobalance sensor are used.)

Safety functions

•Emitter cartridge drop prevention

Locking by double-action •Security cover

Can even more reliably prevent emitter

cartridges from dropping off.

Detects the electric potential difference and

outputs in an analog voltage.

(During sensing DC mode)

•Outputs measured data at a 1 to 5 V

level when a feedback sensor is used.

By outputting the data to a PLC, etc., it

is possible to control static electricity.

•Can be used to remove static electr

from fast-charged or high-potential

wo kpieces or to electrostatically

charge them.

Continuous ion emission of a

desired polarity during DC mode

Applicable to purge pressure

of 0.7 MPa

This reduces the range of surface potential

fluctuations for short installation distances

after static neutralization.

Note) The range of surface potential fluctuations varies depending on the

object’s material, etc.

Light ON

Flash at 4 Hz

Light OFF

635

Alphabetical Index

Length Measuring/

Counter Static Neutralization

Equipment Reduced-wiring

Fieldbus System Position Detection

Switch Flow Sensor Pressure Control Pressure Sensor

A