•Inordertoavoidthataloadswingsinadangerousmanner,itisrecommendedtouseaholdingrope.

•Donotshock-loadchainslingsorjerkloads.

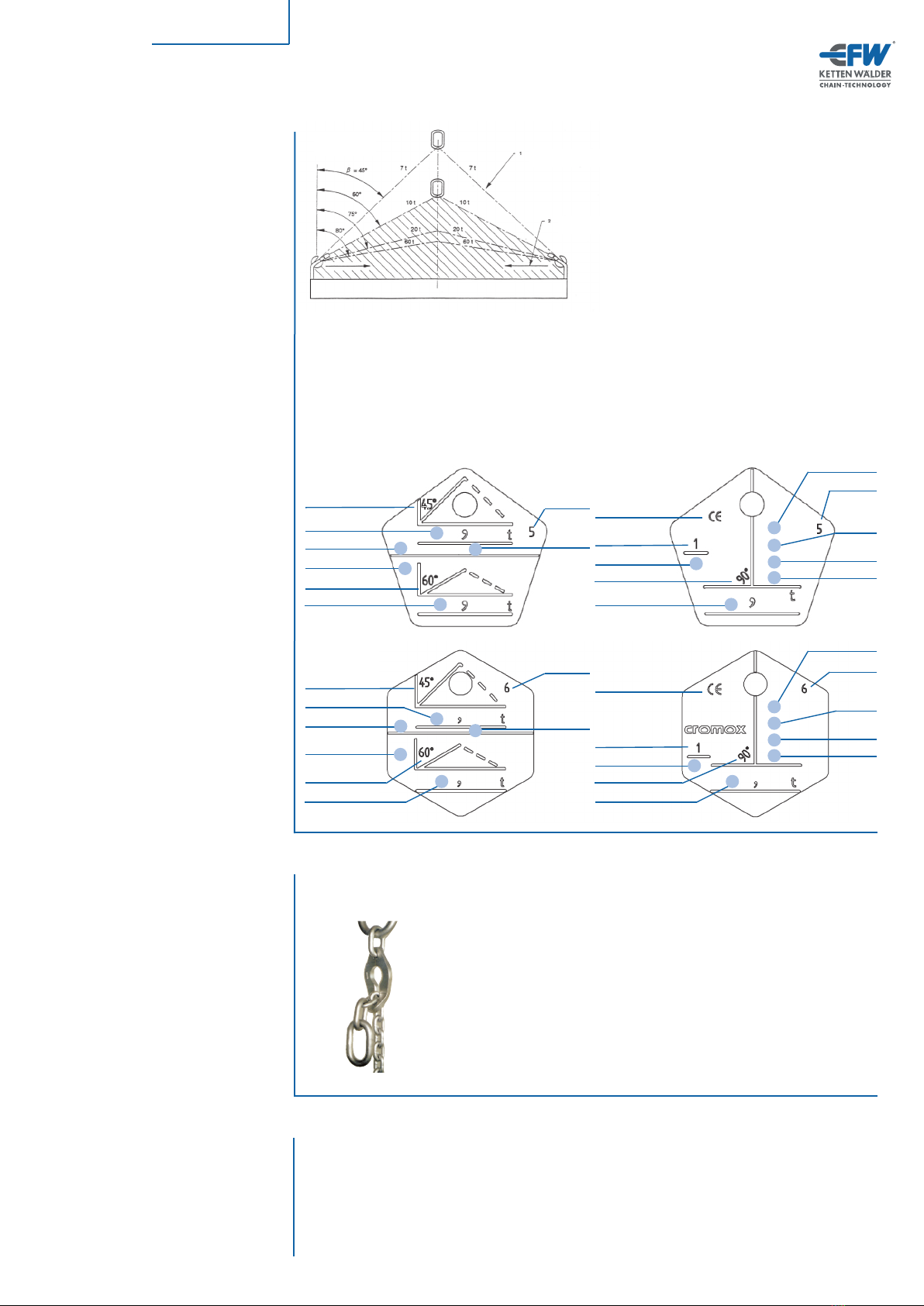

•Inindicatingthesafeworkingload,itisassumedthattheindividuallegsofthechainslingareloaded

symmetrically.Symmetricalloadingcanbeassumedifallofthefollowingconditionsaremet:

utheloadislessthan80%oftheratedsafeworkingloadand

utheangleofinclinationforeachchainlegisnotlessthen15°and

utheanglesofinclinationofthechainlegsdonotdeviatebymorethan15°fromeachotherand

utheslingattachmentpointsfor3-and4-leggedchainslingsarelocatedinasling

planeofnotmorethan15°.

•Forunsymmetricalloading,theclassificationoftheliftingoperationaswellasthedetermination

ofthesafeworkingloadistobeentrustedtoacompetentperson.Alternativelyinthecaseof

unsymmetricalloading,thesafeworkingloadshouldbereducedto50%oftheratedvalue.

•Whenusingmulti-leggedchainslings,thefollowingistobeobservedifnotallofthelegs

arerequiredforlifting:

uIndividuallegswhicharenotbeingusedshouldbehookedbackontothemasterlink.

uInsuchcases,thefollowingloadfactorsapply:

•Allinfluencingfactorsaretobetakenintoaccountwhendeterminingaslingtypeandchoosing

theappropriatechainsling,withthesafeworkingloadtobegreaterthantheloadtobelifted.

•Safetyduringliftingoperations:

uISO12480-1istobeobservedintheplanningandcarryingoutofliftingoperations.

uHandsandotherbodypartsaretobekeptclearwhentauteningthechainsling.

uNootherpersonsmustbeputindanger.

•Theplacewheretheloadistobeputdownshouldbepreparedandmadesufficientlyaccessible.

•Thegroundmusthavesufficientload-bearingcapacity.

•Itmaybenecessarytostabilisetheloadbyusingwoodenblocksorthelike.

•Inordertopreventdamage,theslingchainmustnotbewedged,norpulledoutbymeansoftheliftinggear.

•Storageofchainslingsthatarenotinuse:

uInordertominimisecorrosionattacksonchainslingsthathavebeenusedinacidsoralkalis

orinacidoralkalinevapours,thosechainslingsshouldbecleanedthoroughlyalsobeforeremoving

themfromoperationtemporarily.

uChainslingsshouldbestoredonspeciallydesignedandprovidedracks.

Ifchainslingsarelyingonthefloor,thereisariskthattheymightgetdamaged.

uChainslingsremainingonthecranehookshouldbehookedbackontothemasterlink.

uIfchainslingsarenottobeusedintheforeseeablefuture,theyaretobecleanedandprotectedagainstcorrosion.

Inspectionsshouldbeperformedbyacompetentpersonatintervalsofnomorethan12months.

Ifnecessary,theseintervalsshouldbeshortenedindependenceofthecircumstancesofuse.

•Priortoinspection,thechainslingsaretobecleanedthoroughly.

•Anycleaningmethodthatdoesnotattackthebasicmaterialisadmissible,whereasany

processesorproceduresthatmaycausehydrogenembrittlement,overheatingormaterialabrasion

orwhichmayhidesurfacedamagearetobeavoided.

•Sufficientlightingistobeprovidedduringinspections,andallcomponentsofthechainsling

are to be examined.

•Bymeansofvisualinspections,thechainslingsaretobecheckedforunmistakable

identification(tags)aswellasforanyvisuallynoticeabledefects.

If any of the following defects are found, the chain sling has to be removed from

operation and inspected by a competent person or serviced/repaired:

uMarking/identificationillegibleormissing.

uDeformationofsuspensionorslingparts.

uInadmissibleelongationofchainlinks,differencesinleglengths.

6. When putting

the load down,

the following is

to be observed:

7. Maintenance:

Safety Notes

4

d

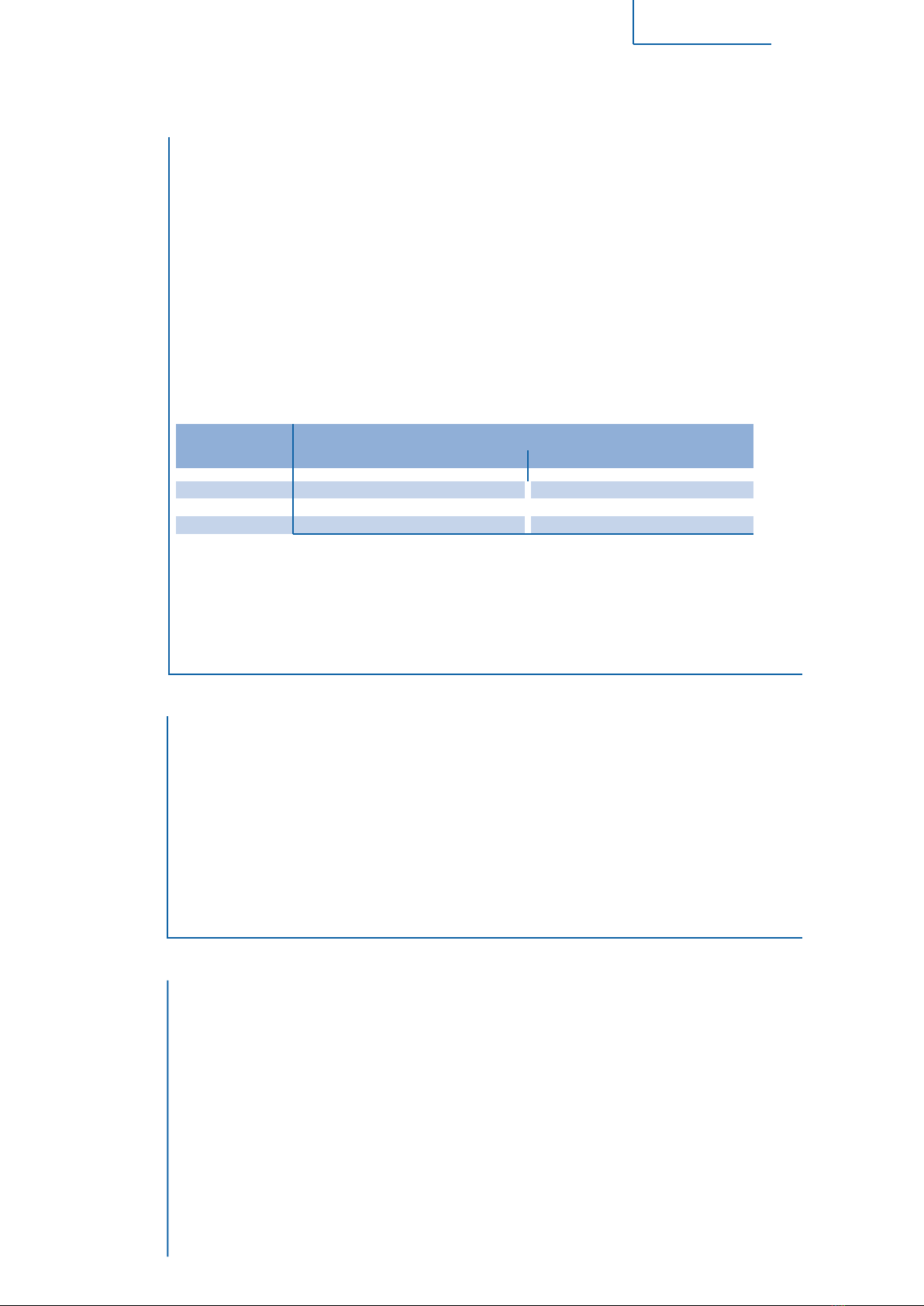

Type of chain sling Number of Factor to be applied with

individual legs used respect to the rated SWL

1 1/2

2 2/3

1 1/3

2- leged

3- and 4-legged

3- and 4-legged