20190711

CHAPTER 2 INSTALLATION AND CAUTIONS

Cautions:

If the generator is installed at a place where difficult for customer access, the water supply valve must be

easy to access for emergencies.

The solenoid valve can endure 0.06-0.55Mpa (0.6-5.5kgf/cm2) water pressure. To protect the solenoid

valve from extremely high water pressure, please turn down the inlet slightly or install water pressure

relieving valve.

Do not install saddle-backed or needle valves on the inlet. Please drain and clean the pipe before

installation.

No block valve should be installed in the steam pipelines. Strictly no blocked or blended pipe, otherwise

have negative effect on the flow of steam and condensate. The steam pipelines should be installed with a

slight angle so that the condensate can flow back to the generator or the steam head.

Steam generator should be installed indoor to avoid frozen. The generator should be installed and leveled

with the arrow pointing upward at an easy-access place, otherwise do not switch on.

The steam pipeline must be copper pipes, all other material such as plastic, acrylic should not be used

since they cannot endure 150℃or higher. temperature

All inlet and apertures should be sealed to prevent any leakage of steam and to protect the generator and

customers.

Draining water to the steam room from the water tank may cause serious scald and damage the steam

room.

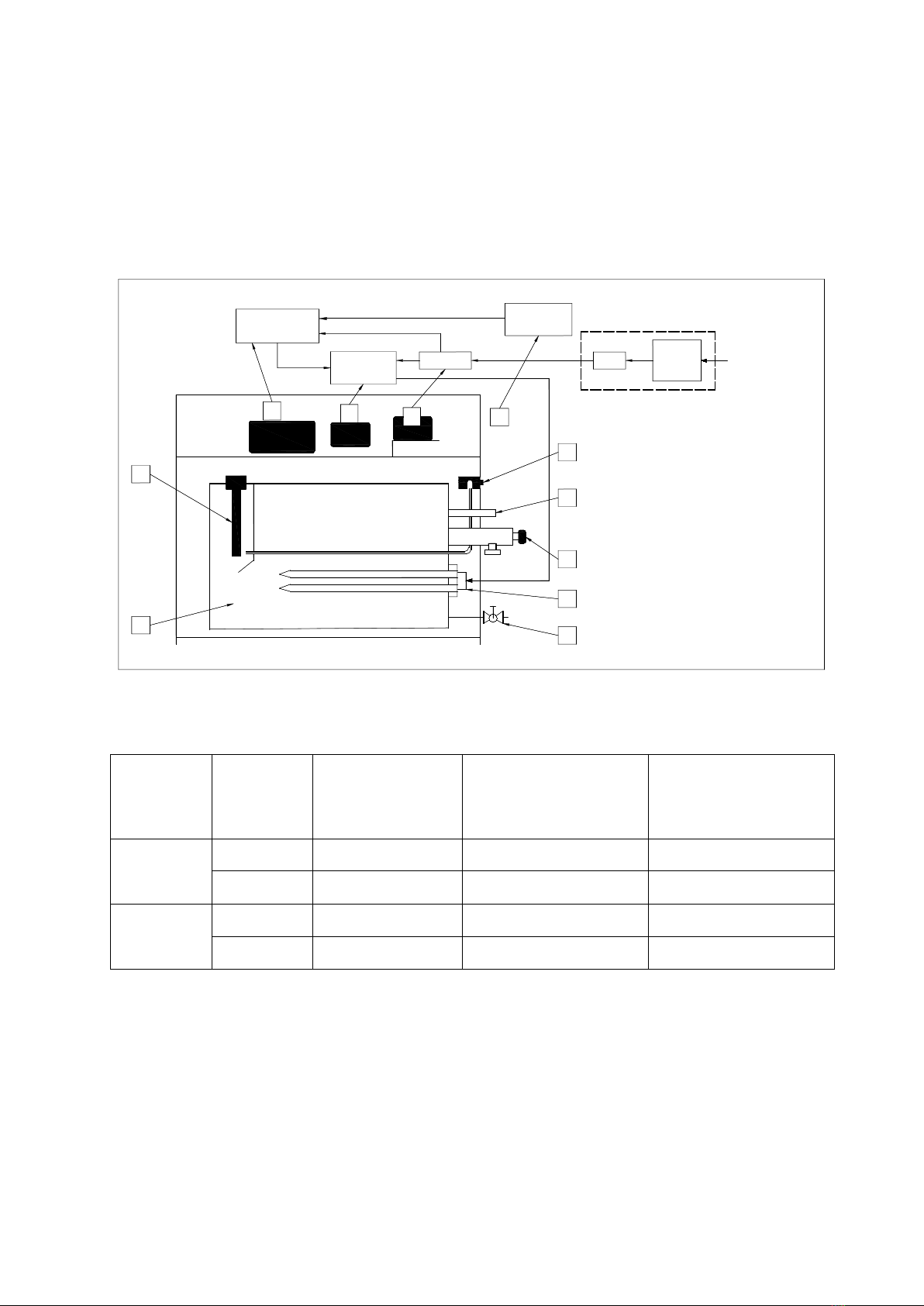

1. Selecting the proper steam generator

In order to achieve comfort and relaxation, as well as energy efficiency, the selection of the correct steam

generator model and size are as critical as design of the steam room itself. The power supply and circuit

protector should be carefully checked to match the parameters of the generator. Please refer to the table 1,table

2 and Chapter 1 Parameters to select the suitable generator and controller for your specification.

2. Installation of steam generator

Switch off all power supply before installation, and check whether you have the correct model for your

steam room according to table 1 and table 2.

Do not install the generator outdoors, in wet/moist place, freezing, or corrosive place. Do not install the

generator near to inflammables such oil paint, diluents and fuel. Be alert to the steam pipeline and safety

valve since the high temperature of steam is dangerous to customers.

Generator must be level installed.

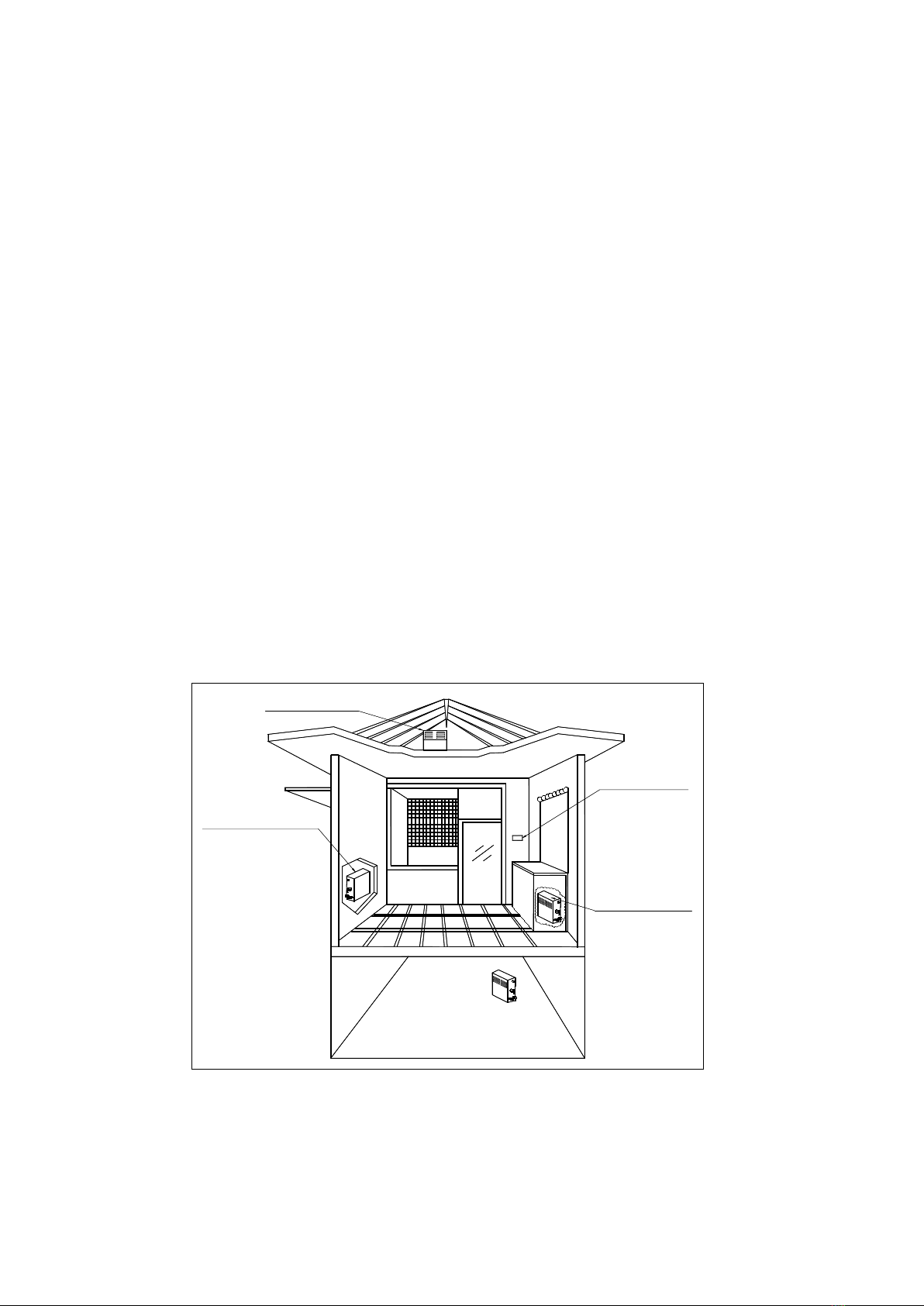

The generator should be installed in a dry and well-ventilated place. It can be installed either on the wall or

on the ground, but must be well fixed. Install the generator as close to steam room as possible, such as in

the closet, under the washing basin or in the basement. (Refer to figure 7).

i. Install the generator on the wall: drill two small holes with diameter of 8 mm on the wall, insert the

expansion screws and then hang the generator on those screws.

ii. Install the generator on the ground or deck: Install the frame on the site and then screw the generator