KEYSCO TOOLS / DIVISION OF S&H INDUSTRIES 5200 Richmond Road Cleveland, OH 44146

PHONE: 216-831-0550 TOLL FREE: 800-253-9726 FAX: 216-831-9573

Rev. 9/29/17

PROUDLY MADE

IN THE U.S.A.

225

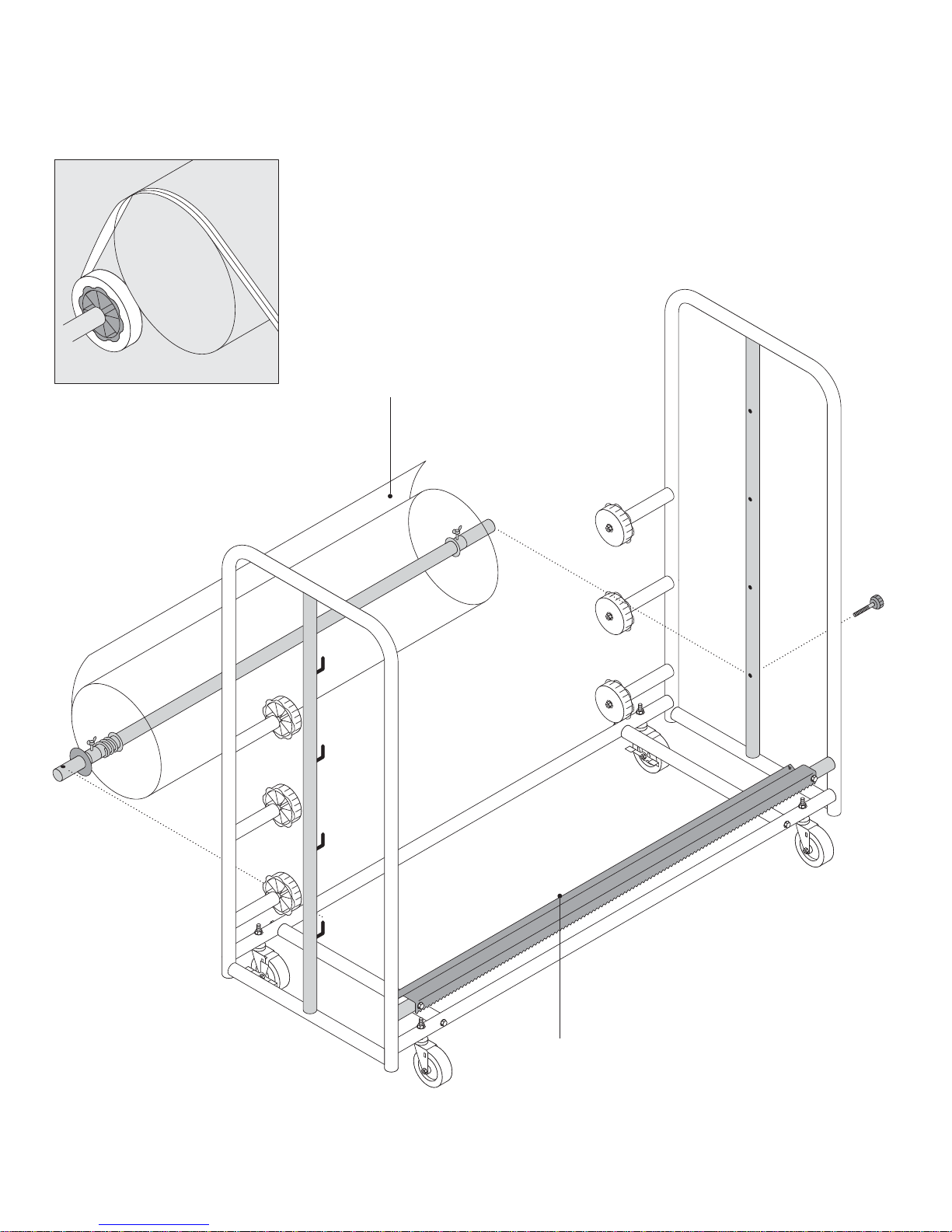

PART#............ DESCRIPTION ...................... QUANTITY

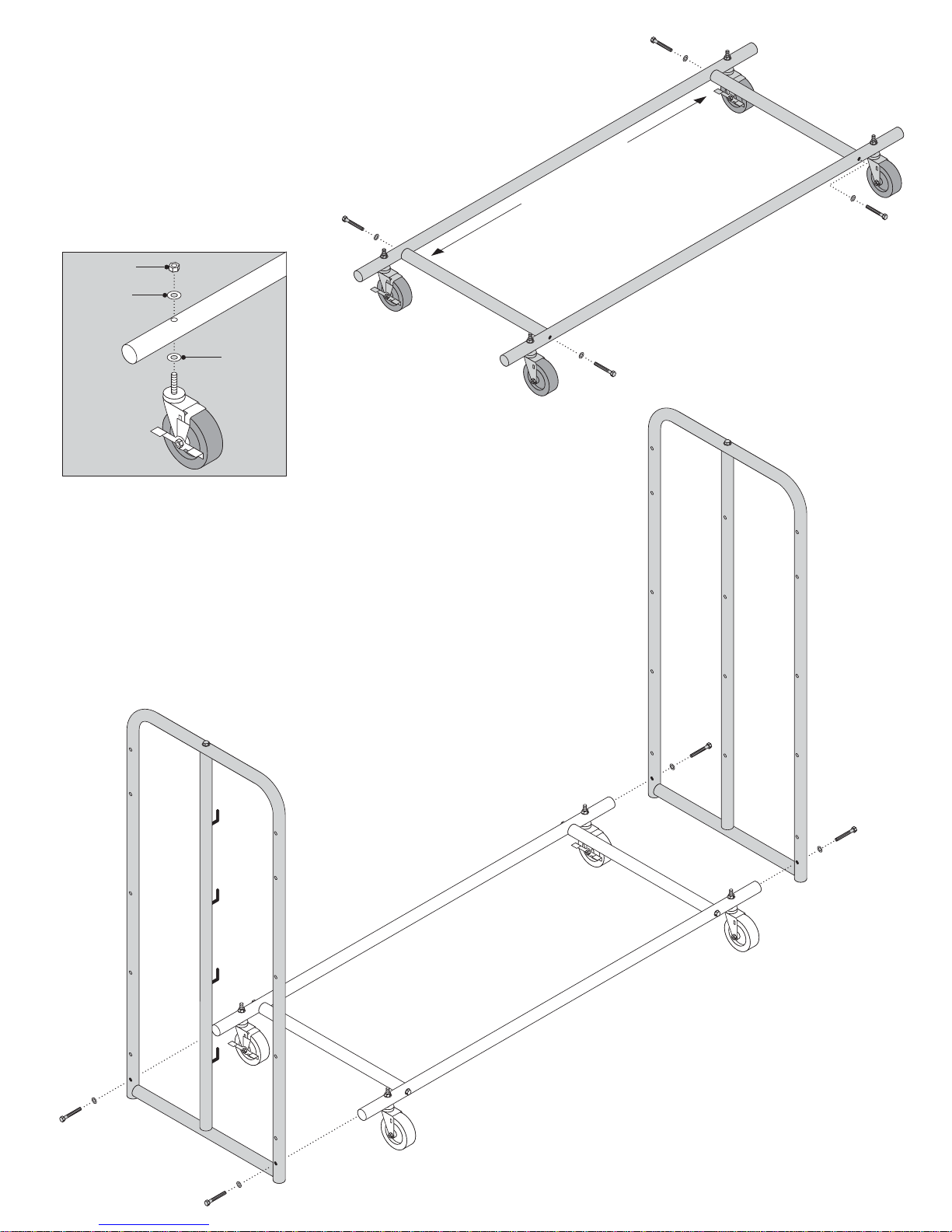

10178 ............ 1/4”-20 Lock Nut ...................................... 6

10202 ............ 3/8”-16 Hex Nut........................................ 4

10204 ............ 1/4”-20 Acorn Nut .................................... 6

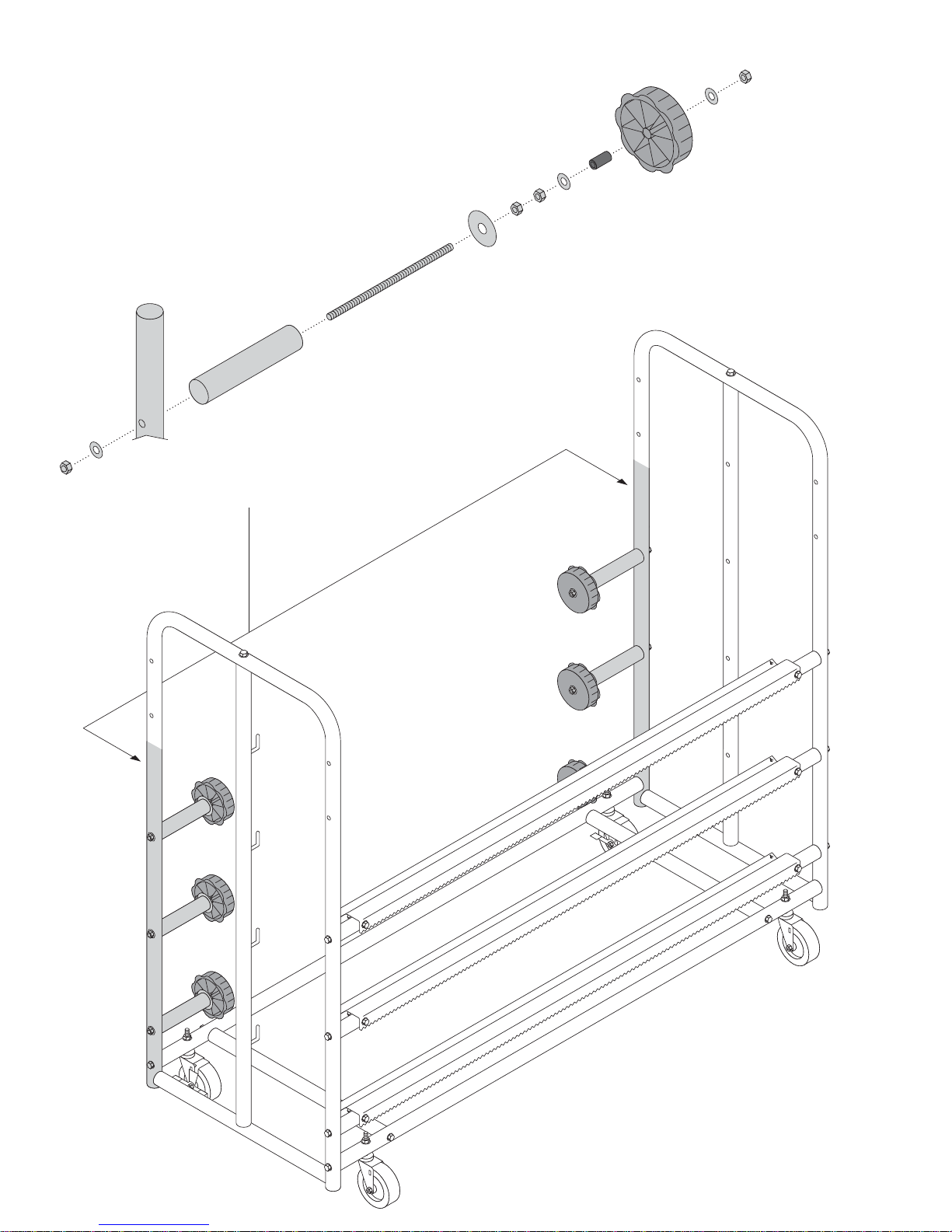

10218 ............ 1/4” Flat Washer .................................... 56

12722 ............ 1/4”X 11/4” Fender Washer...................... 6

12724 ............ 1”X 21/2” Washer.................................... 3

10195 ............ 3/8” Flat Washer ...................................... 8

10678 ............ 1/4”-20 X 2” Knob .................................... 4

10677 ............ Paper Bar Washer................................ 12

10221 ............ Paper Bar Spring .................................... 5

10680 ............ Paper Bar Collar .................................. 12

10755 ............ Swivel Caster.......................................... 2

10756 ............ Swivel Caster with Brake........................ 2

10757 ............ Paint Gun Rod ........................................ 2

PART#............ DESCRIPTION ...................... QUANTITY

11180.............. End Support Assembly (LEFT) .............. 1

12725 ............ End Support Assembly (RIGHT) ............ 1

10750 ............ Lower Horizontal Cross Member............ 2

10741 ............ Horizontal Support.................................. 2

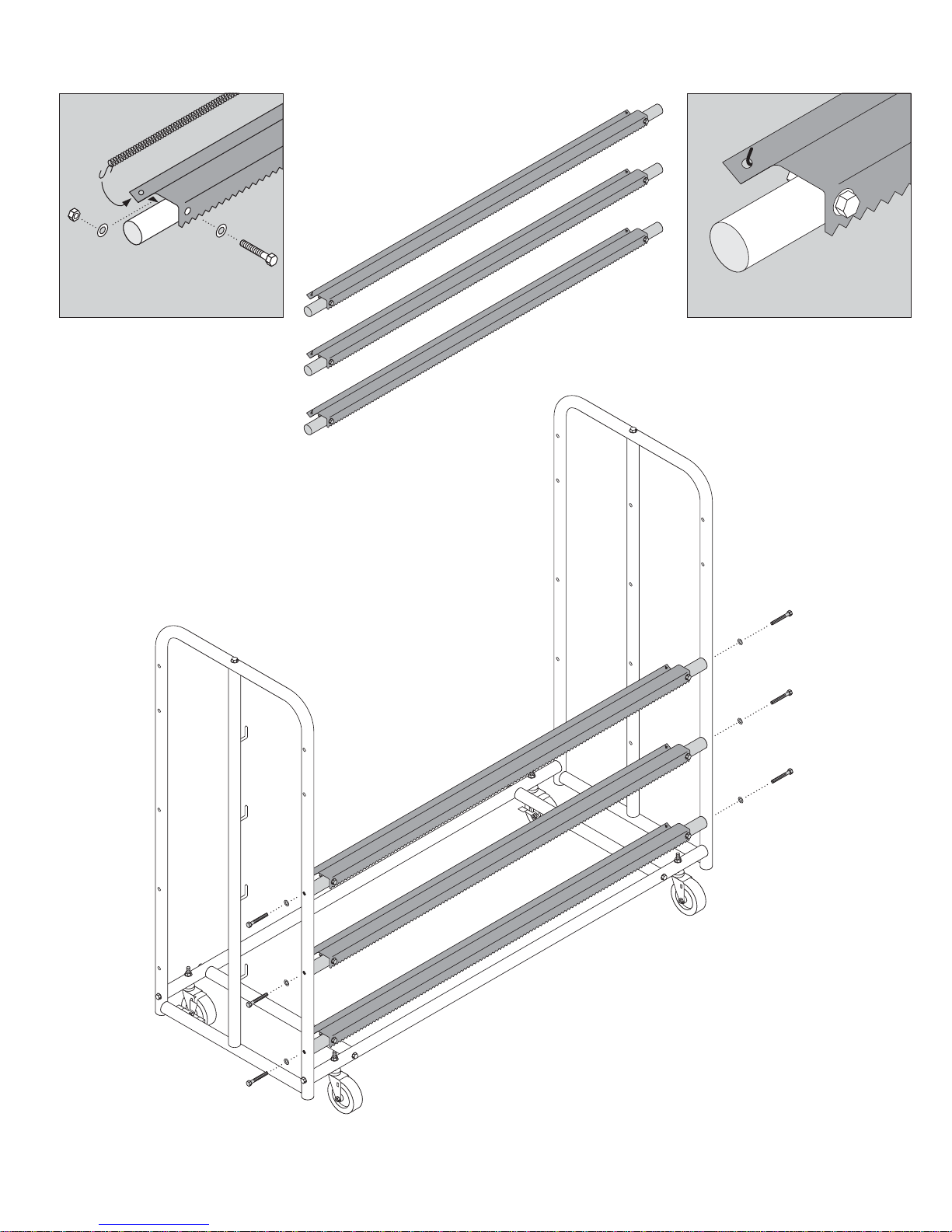

10748 ............ Cutter Bar Retainer ................................ 3

10749 ............ Paper Roll Bar ........................................ 4

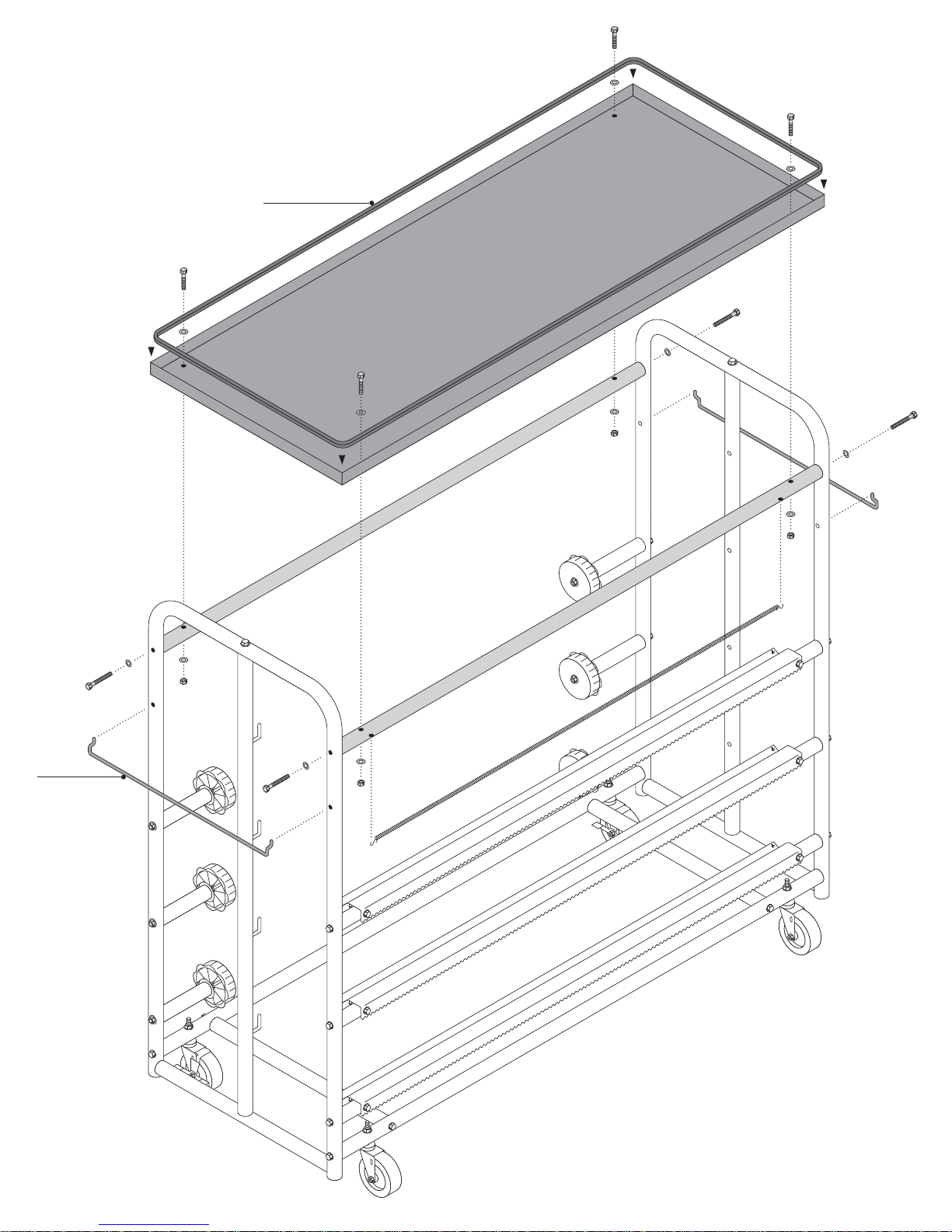

10747 ............ Tray Support .......................................... 2

10754 ............ Tray ........................................................ 1

10696 ............ Cutter Bar .............................................. 3

10689 ............ S-Hook.................................................... 8

10751 ............ Tape Spool Rod...................................... 6

10752 ............ Tape Spool Rod Cover............................ 6

10672 ............ Tape Spool.............................................. 6

10759 ............ Protective Edging (flex rubber) .... 11 Feet

10676 ............ 1/4”-20 X 11/2” Bolt ................................ 10

10675 ............ 1/4”-20 X 2” Bolt .................................... 18

10201 ............ 1/4”-20 Hex Nut...................................... 22

10694 ............ Extension Spring .................................... 4

Prep Station Part #78015

PARTS LIST

PAGE 1