PLZ2004WB/PLZ2004WHB 3

Precautions Concerning

Installation Location

Be sure to observe the following precautions when

installing the product.

• Do not use the product in a flammable atmosphere.

To prevent the possibility of explosion or fire, do not use the

product near alcohol, thinner, or other combustible materials, or in

an atmosphere containing such vapors.

• Avoid locations where the product is exposed to high

temperature or direct sunlight.

Do not install the product near a heater or in areas subject to

drastic temperature changes. For this product's operating and

storage temperatures, see this specifications.

• Avoid high humidity.

Do not install the product in high-humidity locations--near a boiler,

humidifier, or water supply. For this product's operating and

storage humidity, see this specifications. Condensation may occur

even within the operating humidity range. In such cases, do not

use the product until the condensation dries up completely.

• Be sure to use it indoors.

This product is designed for safe indoor use.

• Do not install the product in a corrosive atmosphere.

Do not install the product in a corrosive atmosphere or in

environments containing sulfuric acid mist, etc. This may cause

corrosion of various conductors and bad contacts of terminals

inside the power supply leading to malfunction and failure, or in the

worst case, a fire.

• Do not install the product in a dusty location.

Accumulation of dust can lead to electric shock or fire.

• Do not use the product where ventilation is poor.

Secure adequate space around the product so that air can

circulate around it. Allow at least 20 cm of space between the inlet

and vent holes and any walls or obstructions.

• Do not place objects on the product.

Placing objects on top of the product can cause failures (especially

heavy objects).

• Do not install the product on an inclined surface or location

subject to vibrations.

The product may fall and break or cause personal injury.

• Do not use the product in a location where strong magnetic

or electric fields are nearby or a location where large amount

of distortion and noise is present on the input power supply

waveform.

The product may malfunction.

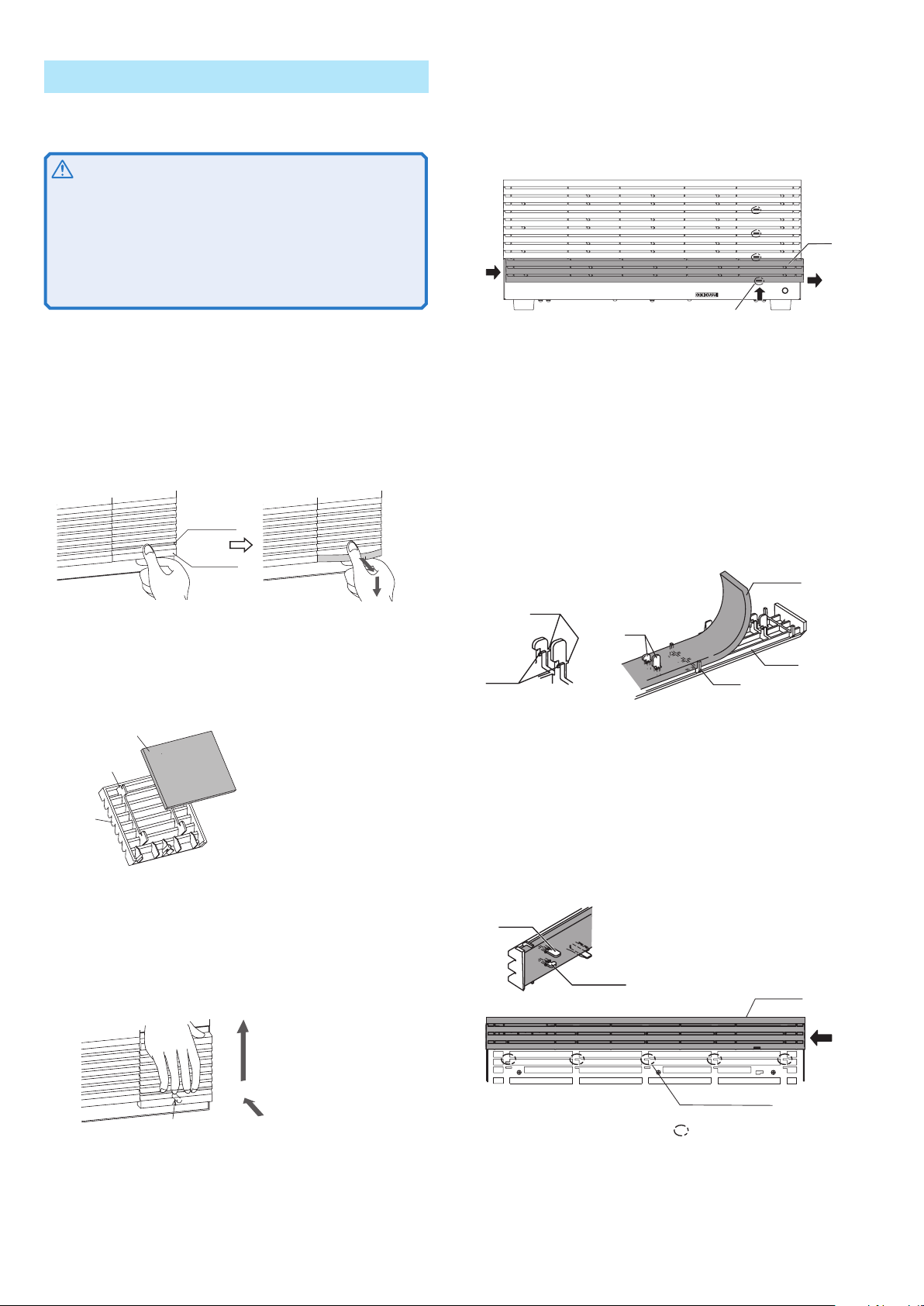

• Do not stack more than two units on top of each other.

The units (load booster and master unit) can be stacked, but

do not stack more than two units on top of each other for safety

reasons. If you are using multiple load boosters, it is recommended

that they be mounted on a rack.

POWER

ELECTRONIC LOAD

PLZ2004WHB

POWER

ELECTRONIC LOAD

PLZ2004WHB POWER

ELECTRONIC LOAD

PLZ2004WHB

I MONOUTOUTTRIG

I MONOUTOUTTRIG

REMOTE

POWER

Do not stack more than two units.

Precautions to Be Taken When

Moving the Product

Note the following points when moving or transporting

the product to the installation location.

• Turn off the power switch.

Moving the product while the power is turned on can cause

electric shock or damage to it.

• Have two or more people move the unit.

The unit weighs over 20 kg. Have two or more people move the

unit. Use extra precaution at inclines and steps.

• Remove all wiring.

Moving the product with the wires connected can cause wires to

break or injuries due to the product falling over.

• When transporting the product, be sure to use the original

packing materials.

Otherwise, damage may result from vibrations or from the

product falling during transportation.

• Be sure to include this manual.

Notation Used in the Guide

• In this manual, the PLZ-4W Series Electronic Load is sometimes

referred to as the “PLZ-4W Series”or "booster." In this manual,

the PLZ-4WH Series Electronic Load is sometimes referred to as

the “PLZ-4WH Series”or "booster."

• In this manual, the PLZ2004W Electronic Load is sometimes

referred to as the “PLZ2004W.”In this manual, the PLZ2004WH

Electronic Load is sometimes referred to as the “PLZ2004WH.”

• The following markings are used in the explanations in the text.

WARNING

• Indicates a potentially hazardous situation which, if ignored,

could result in death or serious injury.

CAUTION

• Indicates a potentially hazardous situation which, if ignored,

may result in damage to the product and other property.

>Indicates menu settings that you select. The menu item to

the left of the > symbol is a higher level menu.