Contents

Chapter One: Identificaiotns of Products..........................................................5

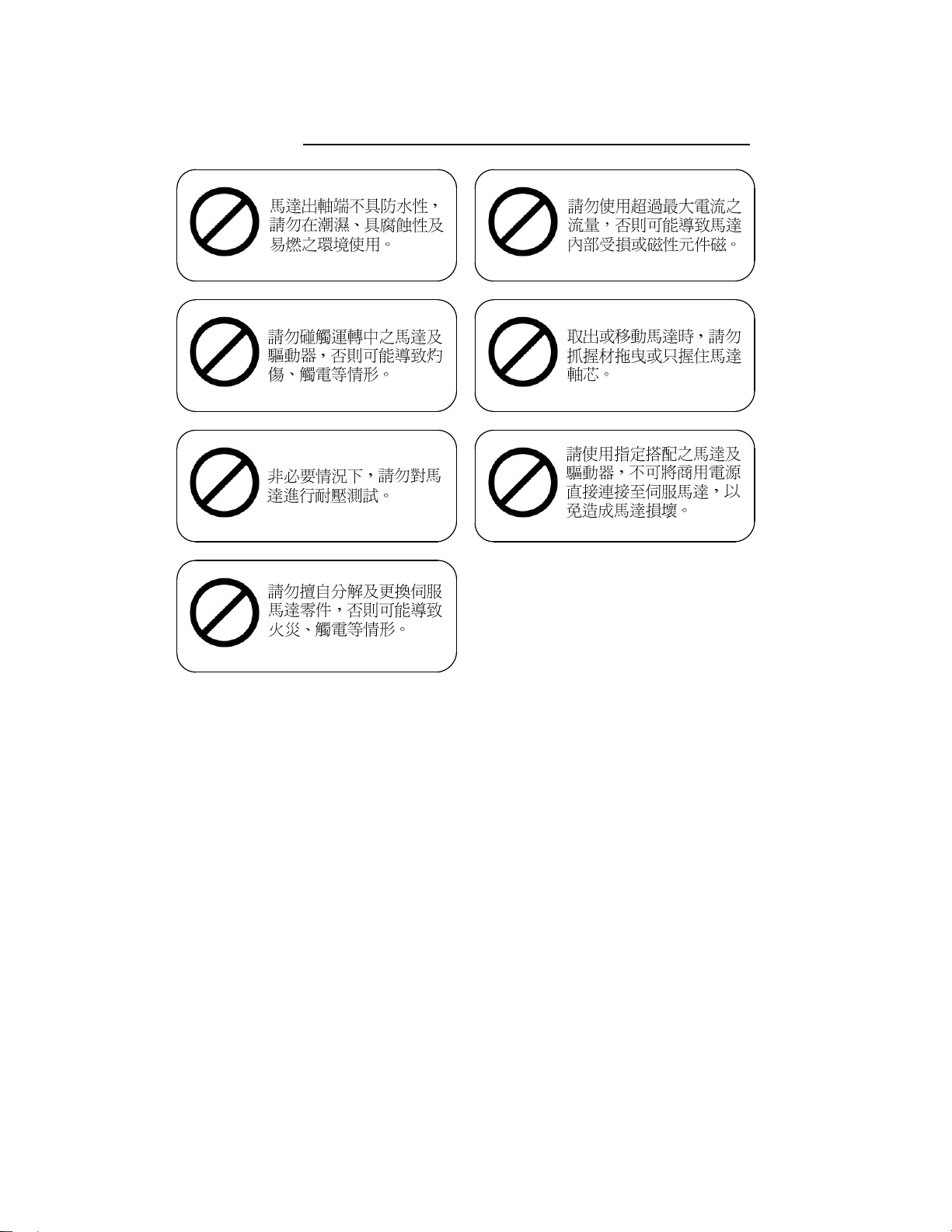

1-1Safety Marking.............................................................................................5

1-2Check before Usage......................................................................................6

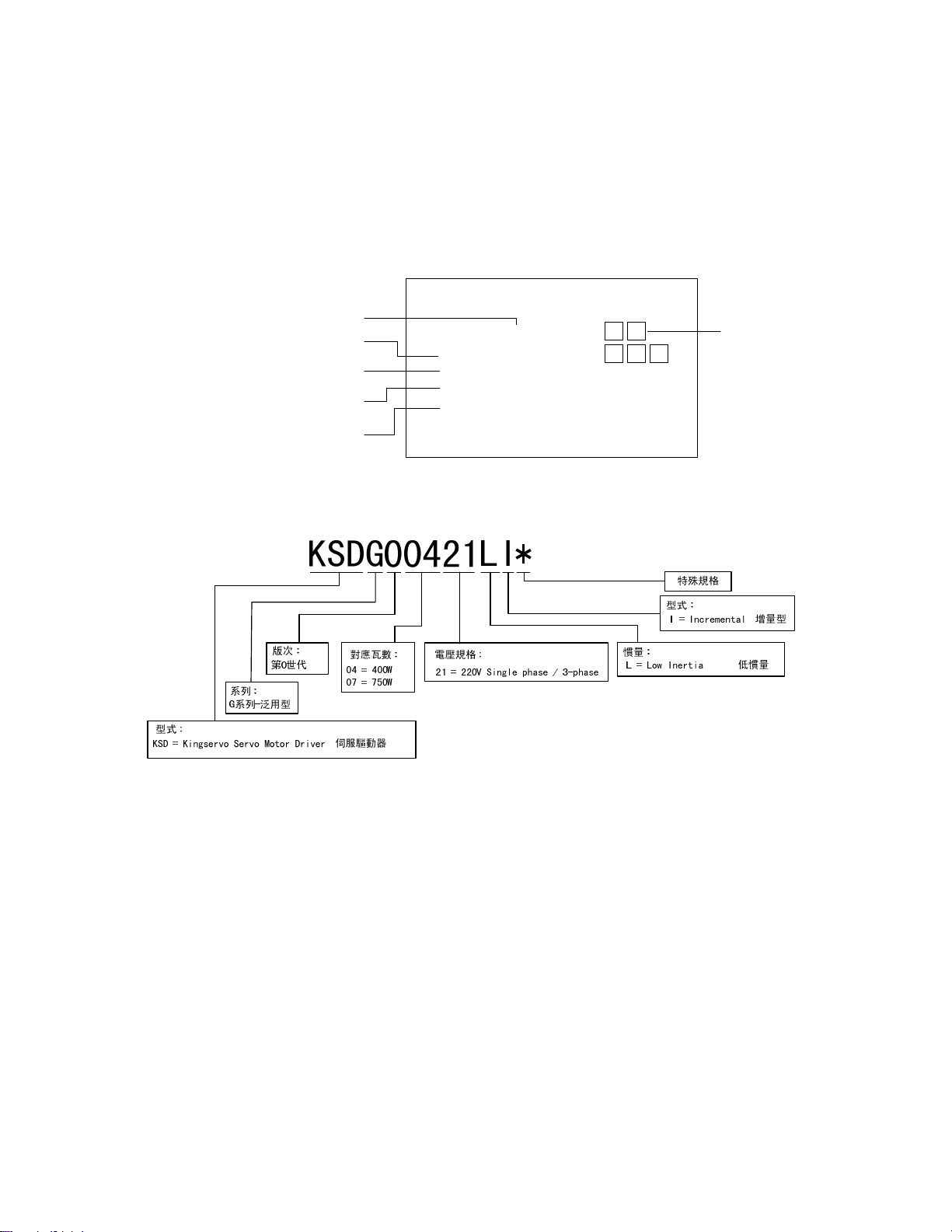

1-3 Indentification of AC Servo Driver Type....................................................7

1-3-1 Name-plate of Driver.........................................................................7

1-3-2 Identificaiton of Driver Type.............................................................7

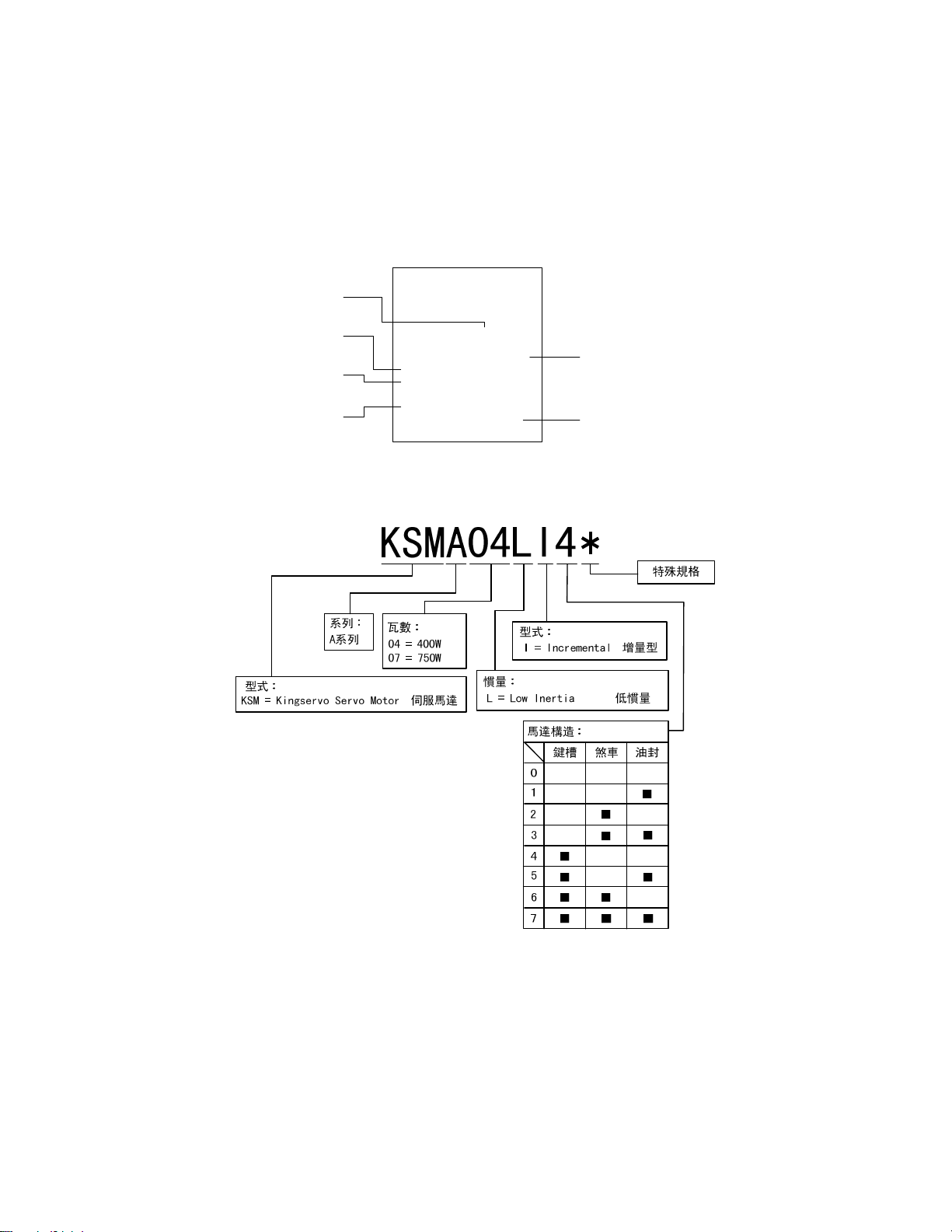

1-4 Encoding Principles of AC Servo Driver Type...........................................8

1-4-1Name-plate of Servo Motor.................................................................8

1-4-2 Identification of Servo Motor Type...................................................8

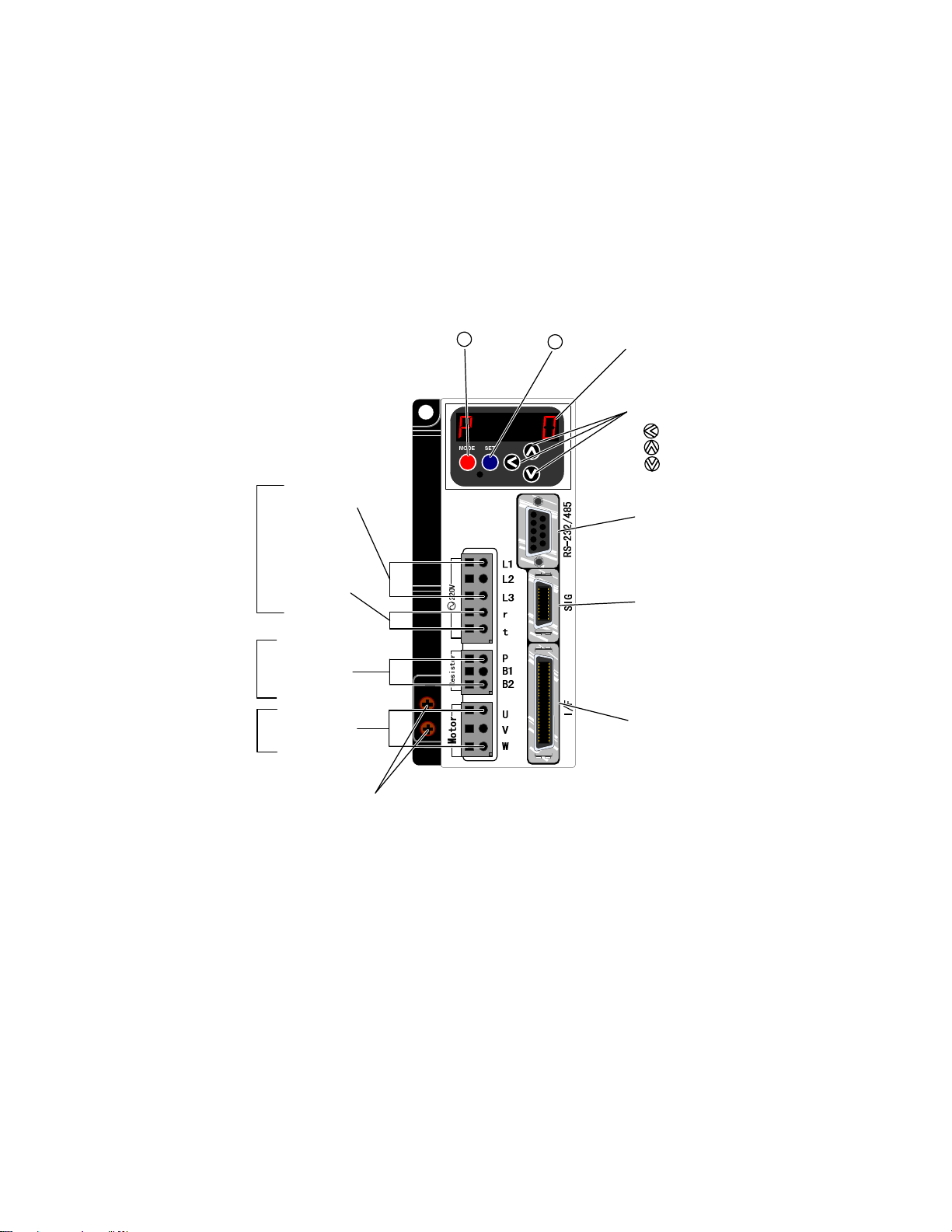

1-5 Names of Parts.............................................................................................9

1-5-1Driver..................................................................................................9

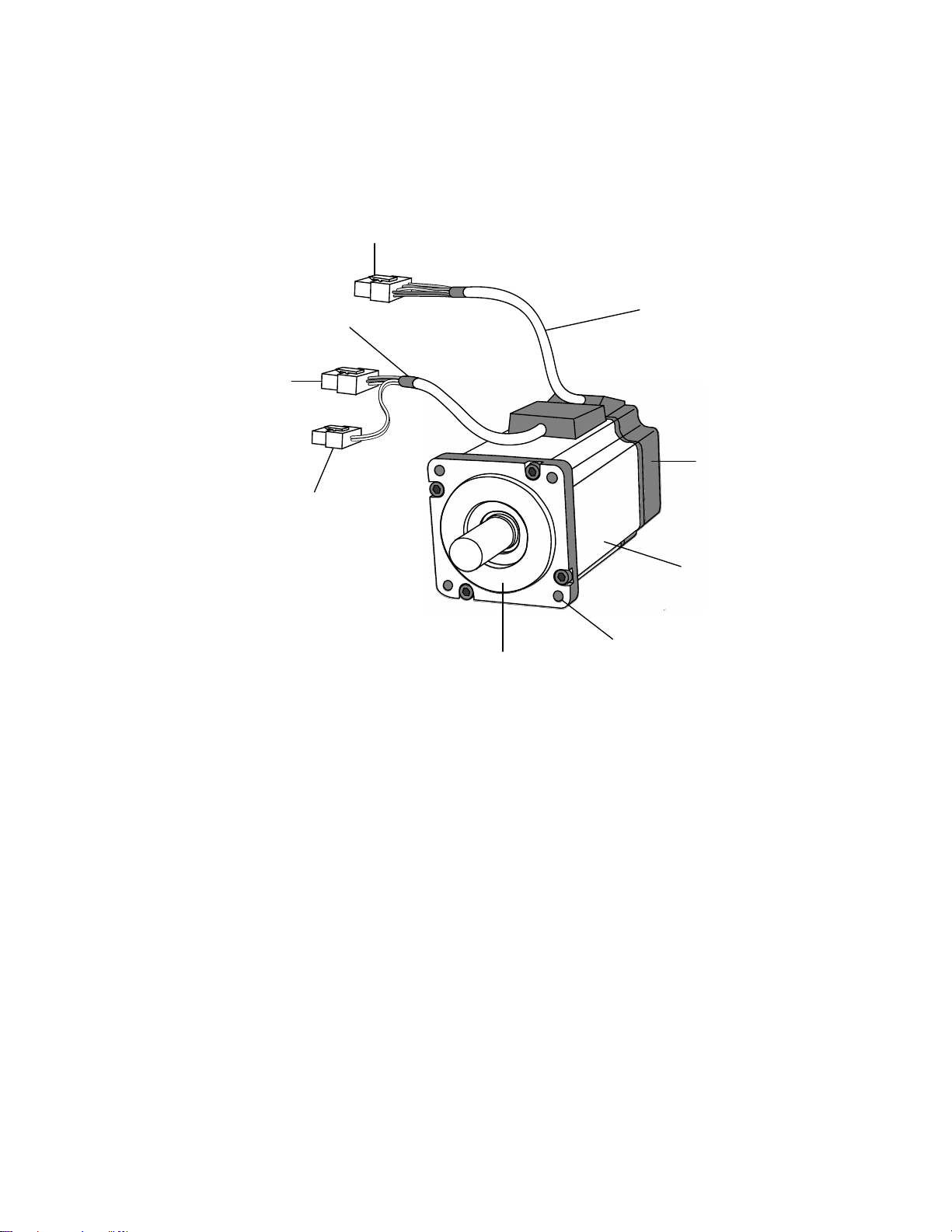

1-5-2 Motor................................................................................................10

1-6 Usage Mode.............................................................................................. 11

Chapter Two: Connectionor and Wiring ....................................................................13

2-1Controller and peripheral configuration map ............................................13

2-2Power wiring diagram................................................................................15

2-3 Defination of Connector Pin.....................................................................17

2-3-1Cable of Encoder...............................................................................17

2-3-2 Power Cable of Motor......................................................................18

2-4 Communication Line of RS-232................................................................19

2-5 Wiring of Connector I/F............................................................................20

2-5-1 Pins of Connector I/F(SCSI II)...... ..................................................21

2-5-2 Signal Modes of Pins........................................................................22

2-5-3 Wiring Diagram of Controlling Mode.............................................23

Chapter Three: Panel Operation .................................................................................27

3-1 Panel Structure..........................................................................................27

3-2 Mode Category and Contents....................................................................28

3-3 Monitoring Modes.....................................................................................29

3-4 Parameters Setting Modes.........................................................................35

3-5 Writing-in Mode of EEPROM..................................................................37

3-5-1 Writing-in Mode of EEPROM .......................... .............................37

3-5-2 Default Writing-in Values of EEPROM .................... ....................38

3-6 Rigid Setting Mode ...................................................................................39

3-7 Auxilary Fuction Mode ............................................................................40

3-7-1Test Run............................................................................................40

3-7-2 Clearance of Abnomality Warning..................................................42