KIRLOSKAR CHILLERS PRIVATE LIMITED

A Kirloskar Group Company IOM-KAC-ENG - Page 5

Chapter 1 Introduction

1.1. General Description

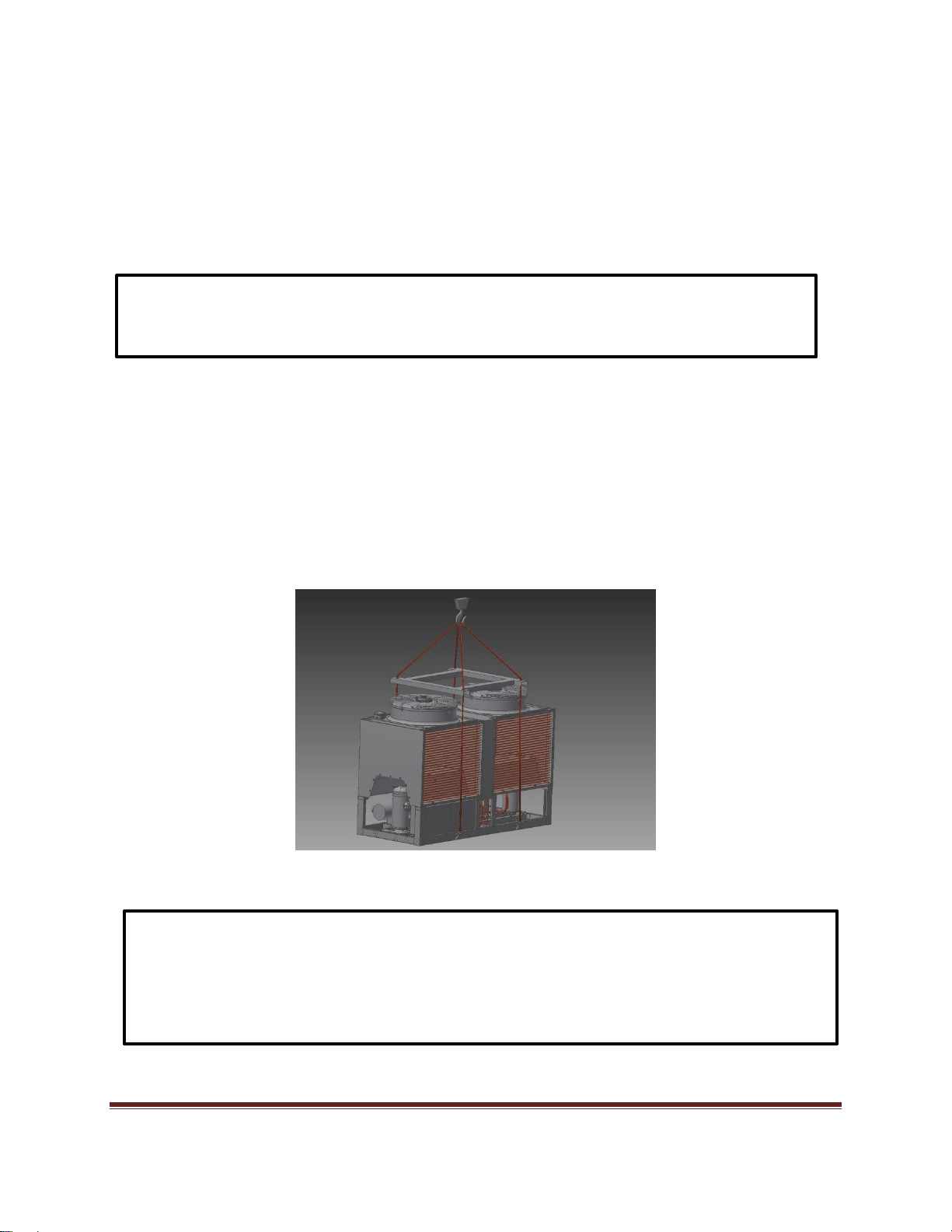

Kirloskar Chillers hermetic scroll liquid chiller, type KAC (Air-cooled) comes complete, self-

contained automatic refrigerating units and ready for installation. These units include the latest in

engineered components arranged to provide a compact and efficient unit. Each unit is completely

factory assembled, factory wired, pressure tested before evacuation, refrigerant and lubricating

oil charged and factory run tested. Run test can be witnessed at an extra cost.

Each KAC unit consists of air-cooled condensers with integral sub-cooler sections, multiple

hermetic compressors, direct expansion (Dx) type shell-and-tube evaporator, complete

refrigerant piping and control panel.

Refrigerant piping components include compressor suction and discharge, main liquid line, main

liquid line filter driers, electronic expansion valves. The control panel includes all safety and

operating controls necessary for dependable automatic operation. Compressors are fused in all

three phases and started by respective three-pole contactors.

1.2. Distinctive Features

1.2.1. Scroll Compressor

A scroll compressor actually consists of two scrolls or spirals. One scroll is moving, whereas

the second one is fixed (attached to the compressor body). The first scroll orbits (rotates) in a

path defined by fixed scroll. The orbiting scroll is connected to the compressor's crankshaft. As a

result of the scroll's movement, gas pockets are formed between the two scrolls. At the outer part

of the scrolls, the pockets suck in gas and then move towards the center of the scroll, where the

compressed gas is discharged. As the gas moves into the continuously smaller internal pockets,

both its temperature and pressure are increased. Thus a desirable discharge pressure is achieved

by the motion of the compressor scrolls.

1.2.2. Reliability

Testing of all units ensures a trouble free start-up. Extensive tests make sure that all safety

controls are adjusted properly and operate correctly.