Everest Glycol System Chiller

lancerbeverage.com Page 8 of 13

Hoshizaki Lancer reserve the right to change specifications without notice No 007 – 5 November 2010

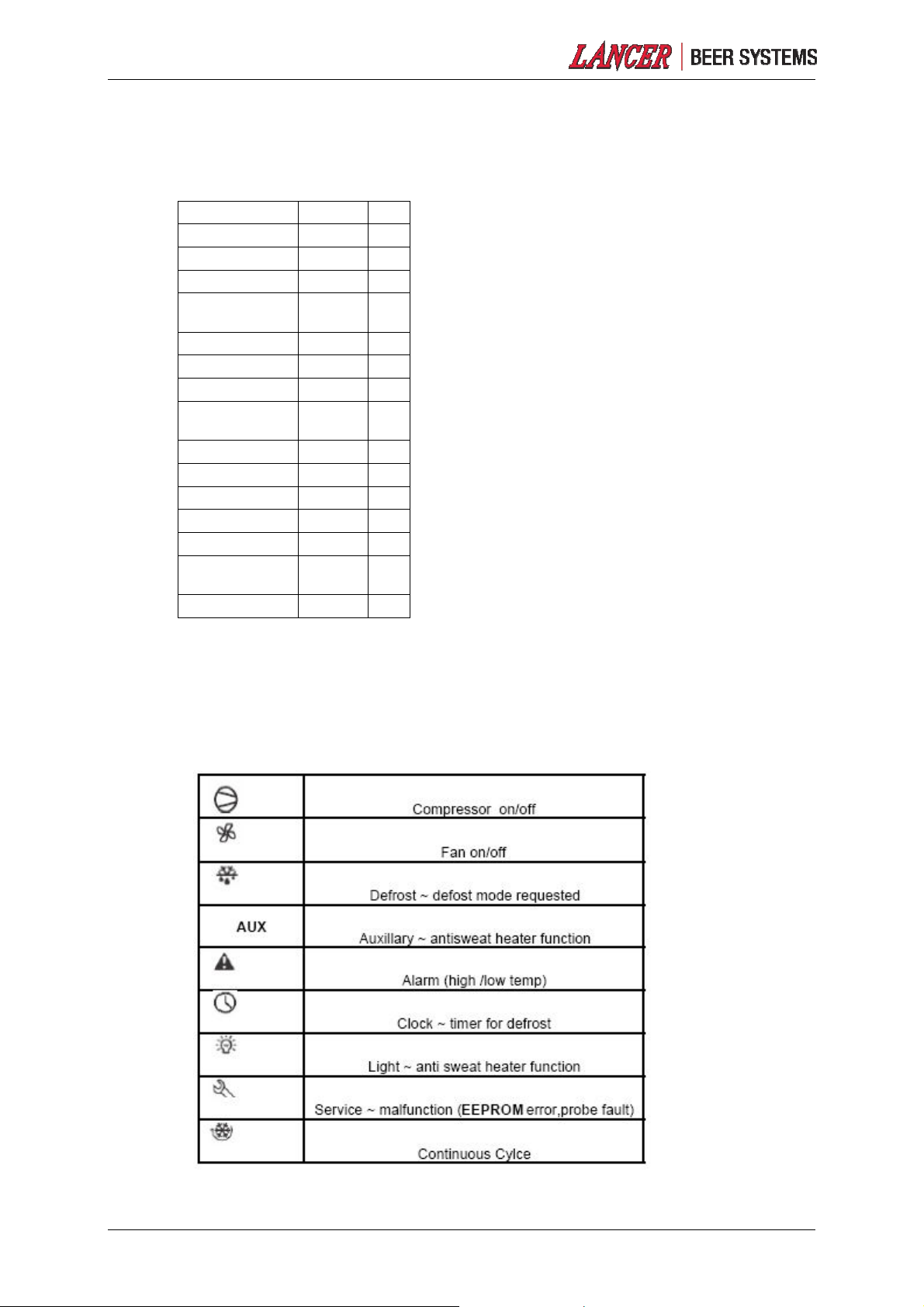

6.1 Alarm Conditions, Causes and Remedies

Message: Er0

Description: Sensor error

Cause: Faulty Sensor

Consequences on

Control Action: Depends on C10

Reset: R: automatic; V: manual

Remedies: Check connections; check sensor signal (eg. NTC = 10k 25°C)

Message: Er1

Description: Sensor NTC2 error

Cause: Faulty Sensor

Consequences on

Control Action: If C19=1 and mode1,2 – refer to Er0;

vice versa control action goes on normally

Reset: R: automatic; V: manual

Remedies: Check connections; check sensor signal (eg. NTC = 10k 25°C)

Message: Er2

Description: Memory error

Cause: Voltage drop during programming state.

Memory damaged by electromagnetic interferences

Consequences on

Control Action: Stoppage

Reset: R: automatic; V: manual

Remedies: Reset factory-set values, turn off the controller,

Turn on again holding down PRG

Message: Er3

Description: Alarm via external contact on digital input

Cause: The contact linked to the digital input is open

Consequences on

Control Action: depending on C31

Reset: R: depends on C29 and C30; V = manual

Remedies: Check C29, C30, C31, and P28; check the external contact Er4

Message: Er4

Description: HIGH Temperature alarm

Cause: P26 has been exceeded for a time-interval > P28 unchanged

Consequences on

Control Action: Control action goes on regularly

Reset: R: automatic; V: manual

Remedies: Check P26, P27, and P28

Message: Er5

Description: LOW Temperature alarm

Cause: P25 has been below P28 for a time-interval > P28 unchanged

Consequences on

Control Action: Control action goes on regularly

Reset: R: automatic; V: automatic (*)

Remedies: Check P26, P27, and P28

R = Control Action / V = Display

(*) = to get manual alarm reset, just give P27 (alarm differential) a high value