Page 9

Advanced Preparations:

1. Read the entire installation guide and users manual thoroughly, understand instructions and warnings.

2. Be familiar with the controls of the range hood by reading through Range Hood Operations, Page 13.

3. Place the range hood on a at, stable surface. Connect the range hood to a designated standard outlet (please refer

the product label for the suitable voltage of this unit) and verify no debris has entered the vent openings, then

turn on the range hood. Verify all operations of the range hood by referring to Range Hood Operations, Page

13.

4. Place all supplied parts and required hardware on a at, stable surface and verify the existence of all supplied parts

listed on Page 4.

5. Carefully remove the white plastic protective coat from the chimney covers and range hood.

Preparations:

NOTE: To avoid damage to your hood, prevent debris from entering the vent opening.

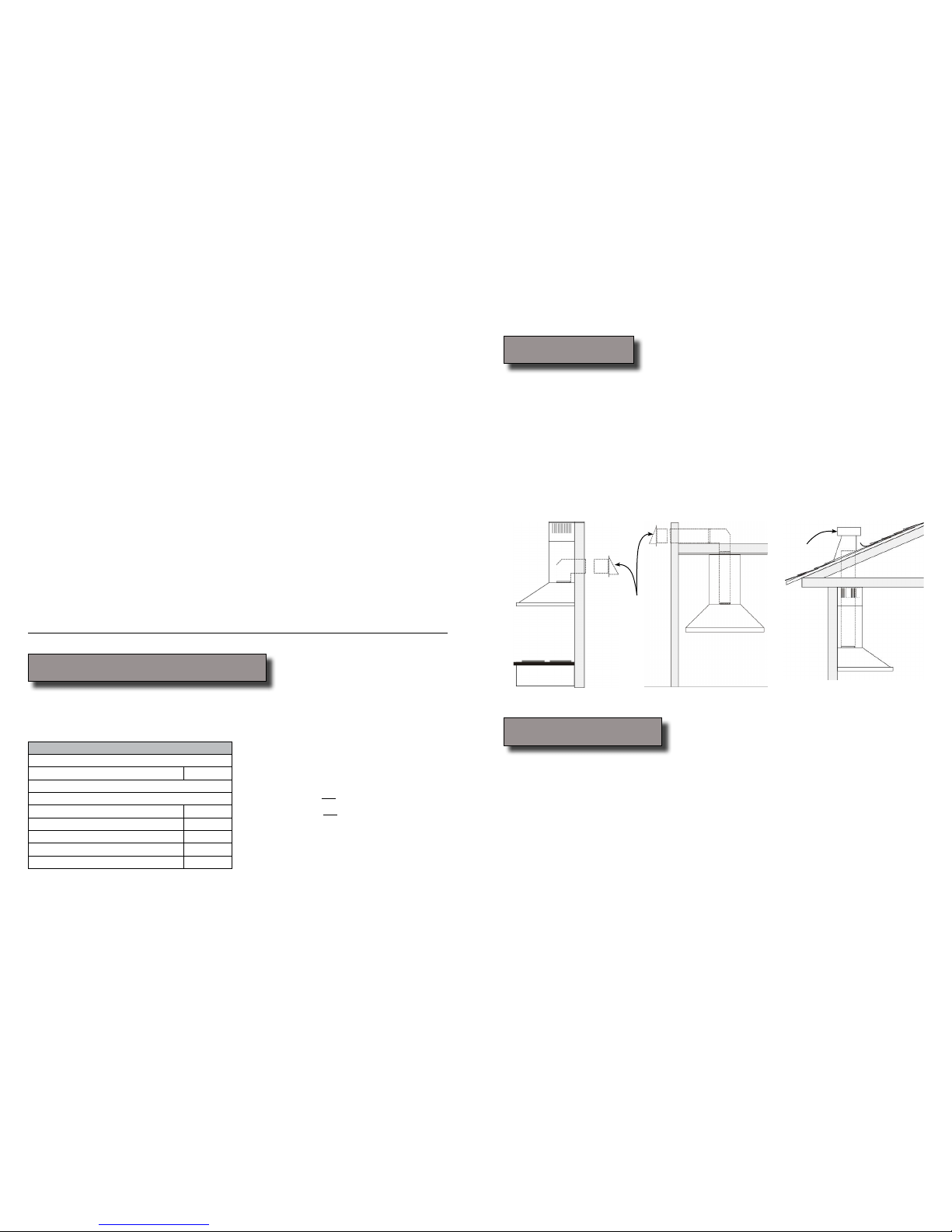

1. Determine and mark the center line on the ceiling where the range hood will be installed. Make sure there is

proper clearance within the ceiling or wall for exhaust vent.

2. Due to the weight and size of this unit, please make sure that the support system or framework being used is stable

and secure in the ceiling.

3. Put a thick, protective covering over counter top, cook top or range to protect from damage or dirt. Remove any

hazardous objects around the area when installing.

4. Mark the locations of the support mounting bracket holes, vent cutout (if used) and power supply cable cutout

on the ceiling. Use drill and saber saw or keyhole saw to cut openings for power supply cable and vent (see

Venting requirements and Electrical requirements, Pages 5-8).

5. If venting to the outside install vent system (see Venting Methods, Page 7). Use caulking to seal exterior wall or

roof openings.

6. Disconnect main electrical supply, prepare and run electrical wiring through ceiling. Leave approximately 12” of

electrical cord hanging from the ceiling. Do not restore power until wiring is completed.

7. Disconnect power cord, remove the aluminum lter by pressing on the latch and gently pull the aluminum lter

down.

8. If charcoal lter is present, unscrew the two screws and remove the lter.

9. Set aside the aluminum lters and charcoal lter until the range hood is properly installed.

10. If the range hood comes with a glass canopy and has not already been mounted to the hood, loosen the four

canopy screws and washers from the hood top, carefully place the canopy on the hood top, and loosely tighten

the four canopy screws along with washers. DO NOT put excessive pressure against the glass.

WARNING

Severe Injury

Rotating fan can cause

severe injury. Stay clear of

fan when motor is running.

Page 8

Electrical Requirements

IMPORTANT: Observe all governing codes and ordinances.

(Please consult with a qualied electrician for 220-Volt 50 Hz voltage)

It is the customer’s responsibility:

To contact a qualied electrical installer.

To assure that the electrical installation is adequate and in conformance with National Electrical Code, ANSI/

NFPA 70 — latest edition*, or CSA Standards C22. 1-94, Canadian Electrical Code, Part 1 and C22. 2 No. 0-M91

- latest edition** and all local codes and ordinances.

• If codes permit and a separate ground wire is used, it is recommended that a qualied electrician determine

that the ground path is adequate.

• A 120-volt, 60 Hz, AC-only, fused electrical supply is required on a separate 15-amp circuit, fused on both

sides of the line.

• Do not ground to a gas pipe.

• Do not have a fuse in the neutral or ground circuit.

• RISK OF ELECTRICAL SHOCK. This range hood must be properly grounded. Check with a qualied elec-

trician if you are not sure whether the range hood is properly grounded.

• The range hood should be connected directly to the fused disconnect (or circuit breaker) box through exible

armored or non-metallic sheathed copper cable. A U.L. - or C.S.A. - listed strain relief must be provided at

each end of the power supply cable. Do not use extension cord or adapter plug with this appliance.

• The range hood must be connected with copper wire/plug only.

• Always use plug provided. If not

possible, connect three wires ac-

cording to its color (black to hot,

white to neutral, and green to

ground) to house wires and cap

with wire connectors:

Wire sizes (copper wire only) and connections must conform with the rating of the appliance as specied on

the model/serial rating label. Wire sizes must conform to the requirements of the National Electrical Code

ANSI/NFPA 70 — latest edition*, or CSA Standards C22. 1-94, Canadian Electrical Code Part 1 and C22.

2 No. 0-M91 - latest edition** and all local codes and ordinances. A U.L. - or C.S.A. - listed conduit con-

nector must be provided at each end of the power supply cable (at the range hood and at the junction box).

Copies of the standards listed may be obtained from:

* National Fire Protection Association ** CSA International

Batterymarch Park 8501 East Pleasant Valley Road

Quincy, Massachusetts 02269 Cleveland, Ohio 44131-5575

WARNING

Severe Injury

Hood may have very shape edges. Please wear

protective gloves if it is necessary to remove

any parts for installing, cleaning or servicing.

Charcoal Filter Installation Preparation

White

Green

Black

NOTE: The charcoal lters are preinstalled if you purchased the range hood with re-circulating kit from us.

1. Remove aluminum lters on hood.

2. Remove the safety lter under the aluminum lter by unscrewing two screws, then position the charcoal lter

and align the screw holes, reinstall and fasten two screws.

3. Reinstall the aluminum lters back to the hood.

4. Charcoal lters must be replaced after 120 hours of use (or approximately every 2 to 3 months based on the

average of 1 to 2 hours of daily cooking time). Available at your local reseller.

WARNING

Excessive Weight

Require three or more person to move and

install this range hood. Spinal or other bodily

injuries could occur if it is not followed.