General information

3

Contents

1General information ...............................................................................................................................5

1.1 Warranty claim................................................................................................................................... 5

1.2 Standards and Directives................................................................................................................... 5

1.3 Information to the instruction manual - target groups........................................................................ 6

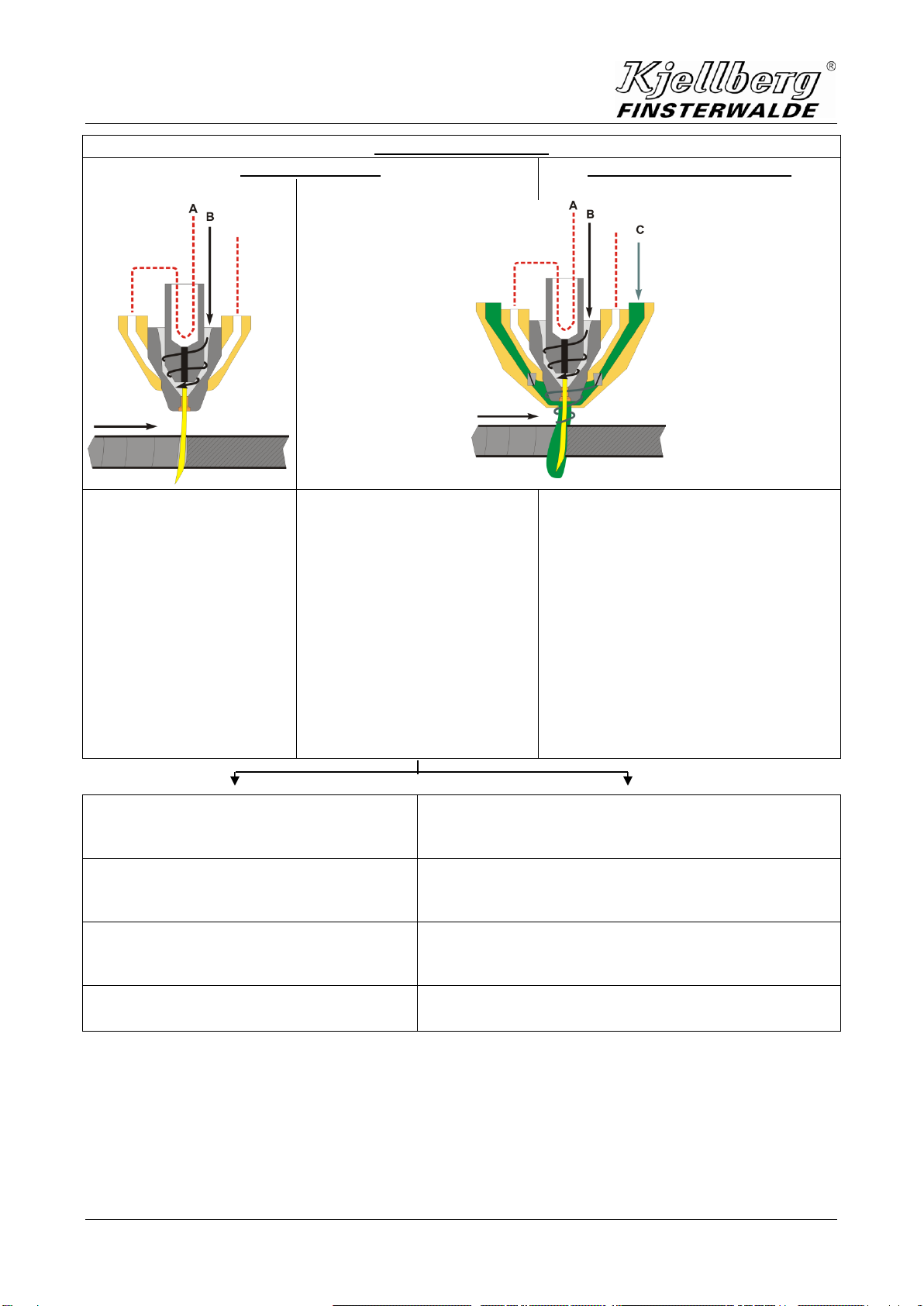

1.4 Plasma cutting as procedure............................................................................................................. 7

2Safety instructions.................................................................................................................................9

2.1 Explanation of the safety symbols..................................................................................................... 9

2.2 Endangerment by high contact voltage ........................................................................................... 15

2.3 Working in environments with increased electric endangerment.................................................... 15

2.4 Endangerment by high voltage ignition ........................................................................................... 16

2.5 Endangerment by electromagnetic fields ........................................................................................ 17

2.6 Endangerment by heat and light radiation....................................................................................... 18

2.7 Endangerment by gases, smoke and types of dust ........................................................................ 19

2.8 Endangerment by oxyhydrogen....................................................................................................... 19

2.9 Endangerment by noise................................................................................................................... 21

2.10 Endangerment by spatter ................................................................................................................ 22

2.11 Handling of pressure reducer .......................................................................................................... 22

3Maintenance..........................................................................................................................................23

3.1 Maintenance general ....................................................................................................................... 23

3.1.1 Intervals of maintenance.............................................................................................................. 23

3.1.2 Cleaning....................................................................................................................................... 24

3.1.2.1 Cleaning of the power source.............................................................................................. 24

3.1.2.2 Cleaning of the gas supply .................................................................................................. 24

3.1.3 Electrical revision......................................................................................................................... 25

3.1.4 Plasma torch................................................................................................................................ 26

4Customer information on repair processing.....................................................................................27

5Disposal.................................................................................................................................................28

5.1 Disposal of the packing material...................................................................................................... 28

5.2 Disposal of the units after decommissioning................................................................................... 28

6Power source CutFire 100i ..................................................................................................................29

6.1 Technical Data................................................................................................................................. 30

6.2 Technical description....................................................................................................................... 31

6.3 Advantages and features of the plasma cutting machine................................................................ 32

6.4 Ranges of application ...................................................................................................................... 33

6.5 Plasma marking, Plasma notching, Plasma punching .................................................................... 34

6.6 Putting into operation....................................................................................................................... 35

6.6.1 Check and placement.................................................................................................................. 35

6.6.2 Installation.................................................................................................................................... 36

6.6.2.1 Mains connection................................................................................................................. 36

6.6.2.2 Connection of the plasma torch........................................................................................... 36

6.6.2.3 Workpiece connection / current return line / potential equalisation..................................... 36

6.6.2.4 Potential equalisation, Earthing........................................................................................... 36

6.7 Connection of the gas supply .......................................................................................................... 37

6.7.1.1 Connections at the rear panel of the power source............................................................. 38