8SAFETY

LASER RADIATION

Laser radiations are micrometric wavelength emissions in the far infrared (CO2 laser), near infrared (Nd-YAG

laser, Nd-YVO4), visible (He: Ne or Argon laser), or ultraviolet (excimer laser) regions of the electromagnetic

spectrum.

They are considered non-ionising radiations. In ENESKAlaser 1500 mobile systems, the emission is produced

by a crystal rod when stimulated by the "optical pumping" generated by a laser power lamp. The photons

rebound continuously between a front mirror and a rear mirror, establishing a positive reaction that results in

their number increasing instant by instant; this continues until they reach the concentration necessary to form

a beam, which is projected through the semi-re ective front mirror. The reaction (which we can imagine as an

"invisible light beam") is then collimated and focused using lens to form a point where the intensity is so high

that it can react with different materials, causing an alteration due to the thermal effect.

This means that, while ENESKAlaser 1500 mobile radiation is invisible to the human eye, it is close to the

threshold of visibility, so that the eye receives it almost in its entirety, but without resulting in a pupillary light

re ex. This, coupled with the fact that the beam is generally very intense, means that it can cause very

serious eye damage or even permanent blindness.

To avoid permanent injuries, it is necessary to follow a series of precautions.

Anyone who may be exposed to harmful levels of laser radiation must be aware of when the laser is active

and ensure they are wearing protective glasses.

Due to its high power, the laser installed on the machine causes laser light to be re ected from at surfaces.

Re ected light is potentially dangerous to the eyes and skin. The micrometric wavelength emission is located

in the far infrared region of the electromagnetic spectrum and is, therefore, invisible to the human eye, this

means that it is not evident where the laser beam is directed.

ABSORPTION OF LASER RADIATION

Human tissue absorbs the electromagnetic radiation differently depending on the wavelength of the radiation

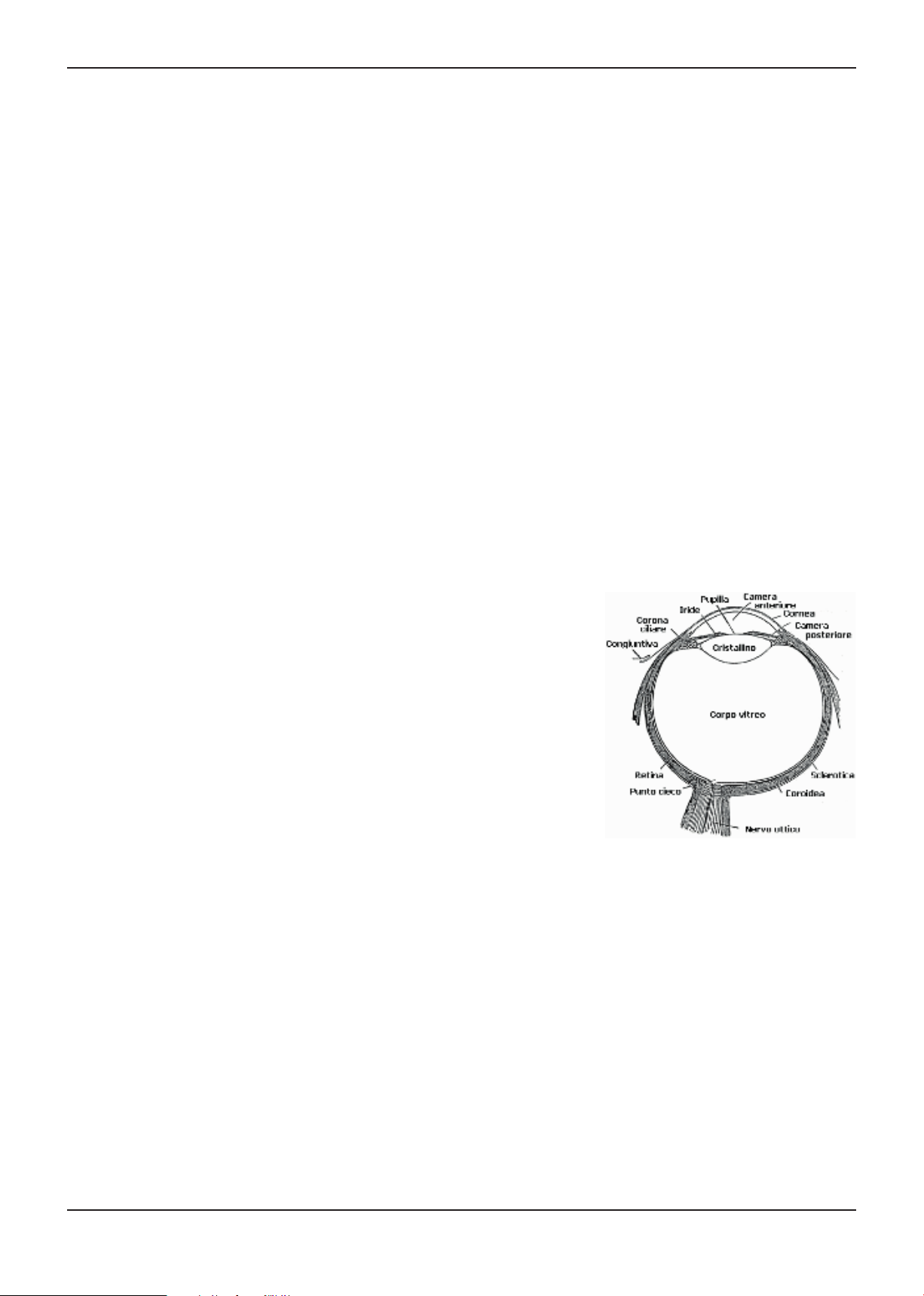

Figure 1 - Eyeball

WARNING: direct exposure to a laser beam can cause irreversible damage to the eyesight.

WARNING: it is essential to protect yourself against beams of re ected light, because they can be

intense enough to cause permanent damage to the eyes or skin.

ATTENTION: This device is equipped with a Class IV laser. Class IV includes all lasers that

can produce risks, not only in the case of the direct or re ected radiation, but also the diffused

radiation. Such laser sources may constitute signi cant risks for the skin, as well as the risk of

igniting in ammable materials.

itself. Both the eye and the skin have their own "predisposition" to absorbing

certain wavelengths, while being more refractory to others. In the case of

the eye, the cornea and the crystalline lens allow all wavelengths between

400 to 1400 nm (corresponding to the region between visible light and

IRA Infrared radiation) to reach the retina, albeit with differing degrees

of attenuation. Therefore, it is immediately apparent that, since Nd: YAG

laser radiation (wavelength 1064 nm) falls within this range, the retina

will be exposed directly to it. With regard to the skin, the "biological

window" differs in terms of absorption percentages but not in terms of

wavelengths. Naturally, the maximum permissible exposure values for

the skin differ considerably compared to the eye.

The damage mechanism caused by absorbed radiation also depends on

the wavelength. Short wavelengths (ultraviolet UV-C 180-280nm, UV-B

180-280nm, UV-A 315-400nm) generally cause photochemical effects:

cataract or opaci cation of the lens in the case of the eye, and melanic colouring or reddening in the case

of the skin. Longer wavelengths (infrared: IR-a 780-1400nm IR-c 3000-10 E6nm) generally cause thermal

effects: detachment and photo-coagulation of the retina in the case of the eye, and burns in the case of the

skin. Naturally, the degree of damage caused depends on the amount of radiation absorbed and on the

instantaneous power of the radiation source.