HM700A1000

How the Humidifier Works

The HM700 is an atmospheric steam generator that uses heat

generated by electrical current flowing between submerged

electrodes to generate steam. The HM700 is designed for on-

demand air humidification via a steam distributor.

STEAM GENERATION

pOnce the unit receives a demand signal and the safety loop

between terminal 1 and 2 is closed, the humidifier closes

the contactor and measures the electrical current.

pIf the demand is lower than the actual output the inlet valve

is kept closed and output is reduced by letting the water

level in the cylinder decrease by evaporation.

pIf demand is higher than the actual output, after a brief

delay the fill valve is activated and water flows into the fill

cup. Water from the fill cup flows into the bottom of the

cylinder through a hose connected to the drain valve

housing.

NOTE: The cylinder is gravity fed from the fill cup. If

backpressure from the steam line is too high it

will cause water to back up in the fill cup and

flow down the overflow line to the drain.

pAs soon as the water in the cylinder comes in contact with

the energized electrodes, current flows through the water.

The resistance of the water to the electrical charge

generates heat and in turn steam. The electrical current

(and steam output) increases as the level of water

increases, as more of the electrode becomes submerged.

The unit continues to fill until the current matches demand

or the high water sensor detects a high water level.

pThe HM700 repeats the fill and boil down cycle repeatedly

to match output to demand.

pOver time minerals in the water will adhere to the cylinder

electrodes. The humidifier will automatically fill to a higher

water level to maintain full capacity during the life of the

cylinder. Eventually because of scale formation it will no

longer be possible for the humidifier to reach its full

capacity. The HM700 software monitors this condition and,

when detected, will stop operating and flash the yellow

LED in a repeating sequence of 4 flashes.

DRAINS

pAs steam is produced, minerals are left behind, increasing

the conductivity of the water. The HM700 patented auto

adaptive cycle will monitor the water conductivity and

perform drains to maintain the water at optimal conductivity

for peak performance.

pThe auto adaptive cycle ensures cylinder life is maximized.

It does this by keeping the tightest control and most

efficient use of water during the entire cylinder life.

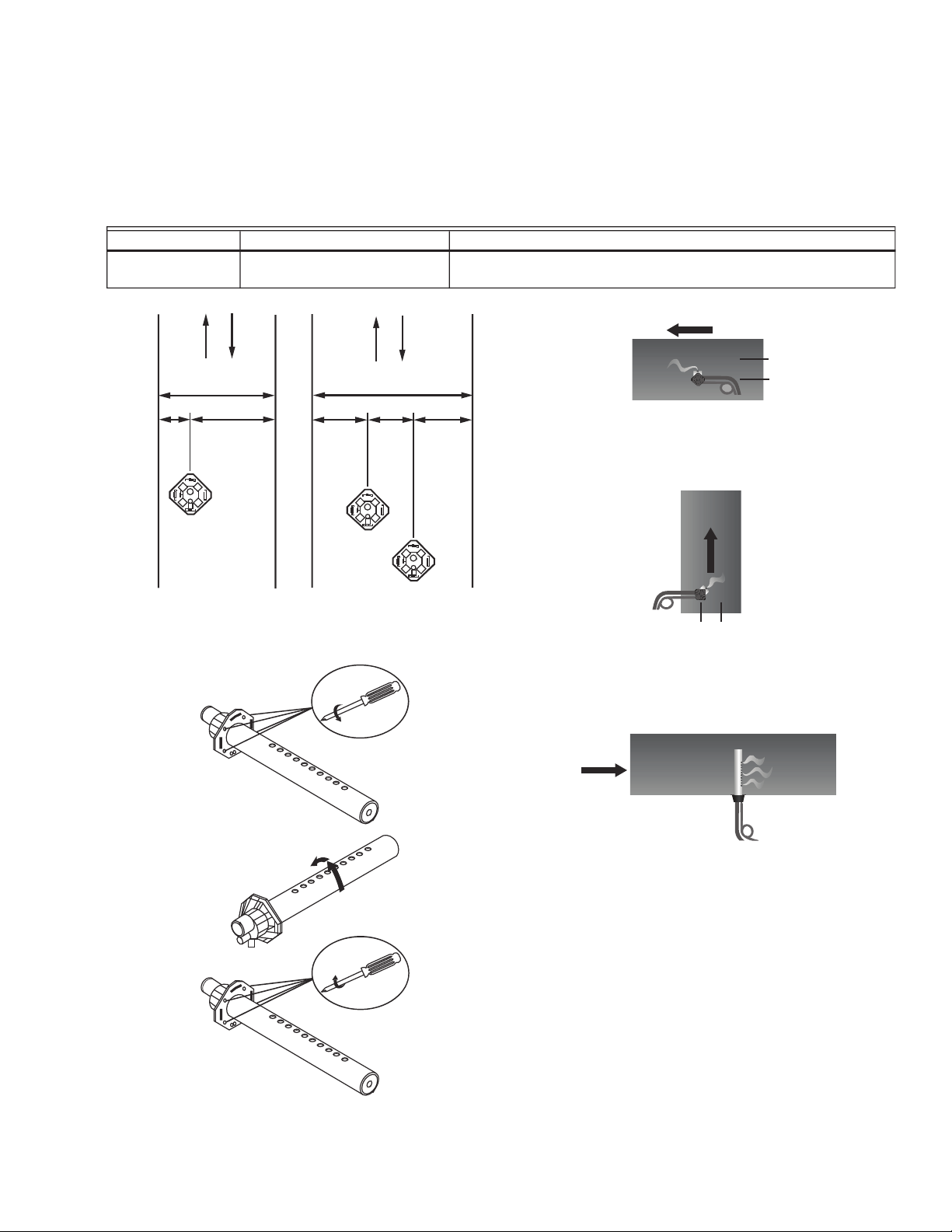

STEAM DISTRIBUTION

Steam generated by the humidifier may be introduced into the

air in several different ways. The most common method for

adding the steam into the air is to mount a steam distributor

tube in a supply air duct.

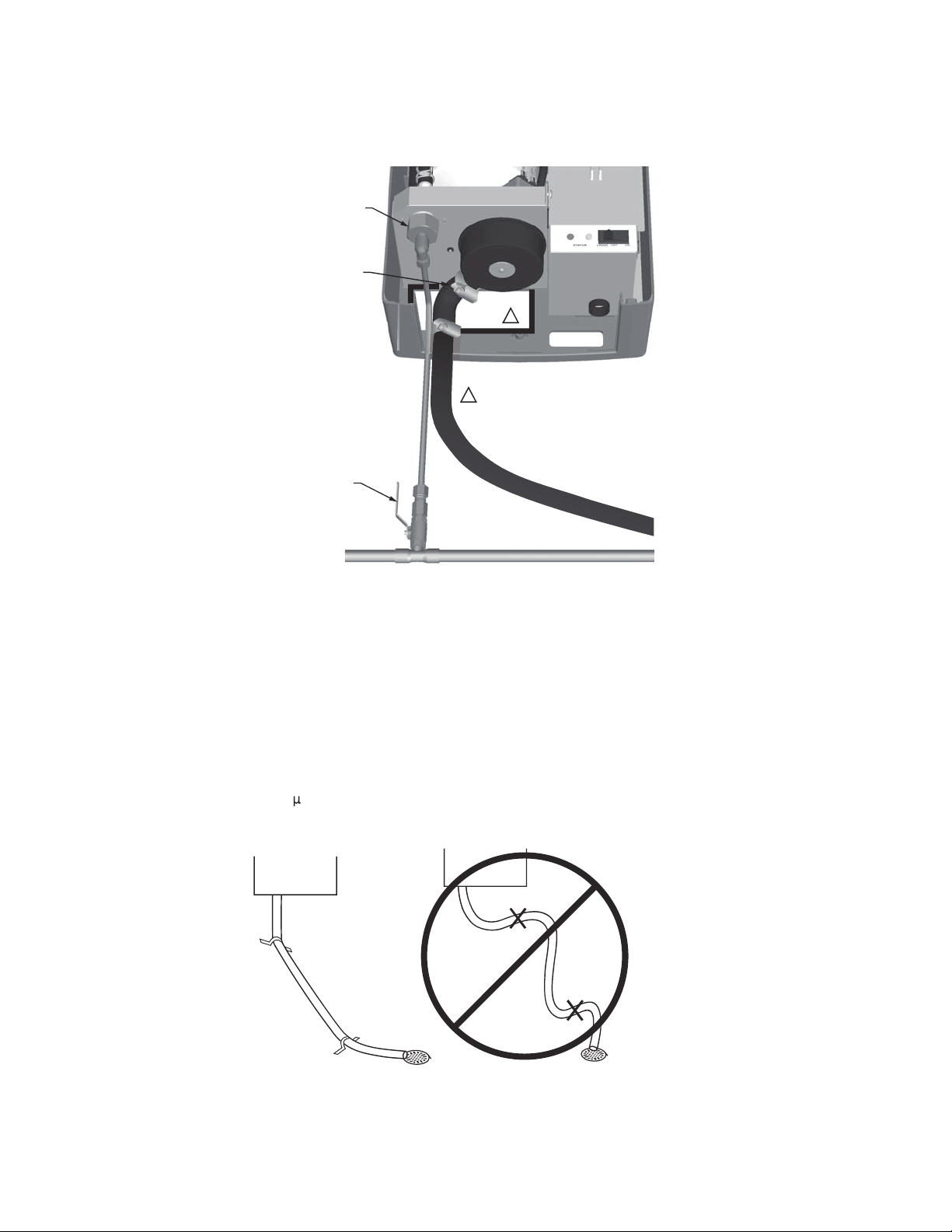

STEAM LINE

The steam line between the cylinder steam outlet and the

distributor serves two purposes: it is used as a conduit to

transfer the atmospheric steam from the humidifier to the

distributor, as well as providing a means to remove

condensate. See nSteam Lines and Condensate Return

Instructionsoon page 8 for information on selecting steam

lines.

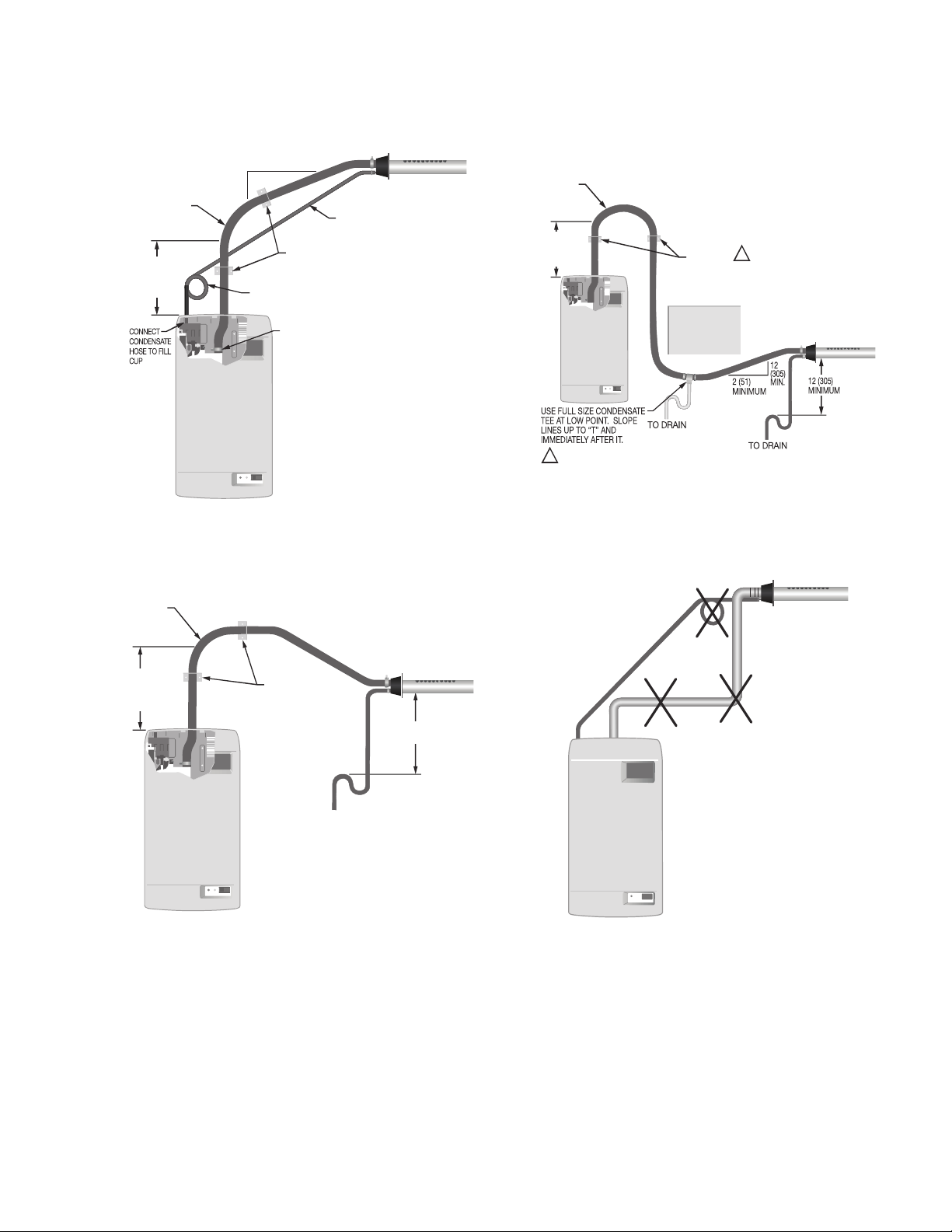

CONDENSATE RETURN

Whenever steam is distributed condensate is formed in the

distribution system. Insulating steam lines is one important

way to reduce the amount of condensate formed. Steam lines

are sloped so that condensate does not collect in the lines and

create a restriction to steam flow. The condensate must be

collected and removed from the system so that it does not

build up and leak into the duct. Condensate can be returned to

the HM700 fill cup to reduce water waste or can be fed to

drain.