Steam Lines and Condensate Return Instructions

The following instructions must be followed for installation of steam lines for the HM700. Failure to use recommended

material and exceeding maximum recommended length in Table 4, or failure to follow any other steam line installation

instructions will result in improper operation and could void the warranty.

Table 1. Recommended Steam Line Material for HM700 Duct.

*The use of steam line other than copper, stainless steel tube or Honeywell supplied steam line will void the warranty

and may adversely affect the operation of the humidifier.

*When using copper or stainless steel tubing (other than the supplied tubing), insulation is recommended due to high

temperature safety as well as reduced condensate.

CAUTION

Plumbing to be performed by licensed HVAC

professionals only.

Drain water from humidifier can be very hot. Do

not drain to public sink.

All plumbing work should be done according to

local plumbing code.

CAUTION

Installation

Do not mount in area where freezing can occur.

Do not mount on floor.

Humidifiers produce steam at atmospheric

pressure. No devices which could block steam

output should be connected to the steam outlet.

Steam lines must be installed so that no restriction

can produce backpressure in the humidifier.

Regardless of selecting on/off or modulating

control method, Honeywell humidifiers must

have a closed circuit across its on/off security

loop control terminal to operate. Honeywell

highly recommends the use of a duct high limit

humidistat.

Steam Line Installation

1. Honeywell steam hose should only be used on

short steam runs (under 15 feet).

2. Ensure that no condensate produced in the steam

line will remain trapped. Steam naturally flows

upward and condensate naturally flows downward.

3. Ensure steam line properly supported so that no

sags or dips are present.

4. All bends should be done in large radius 12 in.

minimum. Steam hose will soften when and may

kick if too tight a radius is used which can cause a

blockage and excessive back pressure.

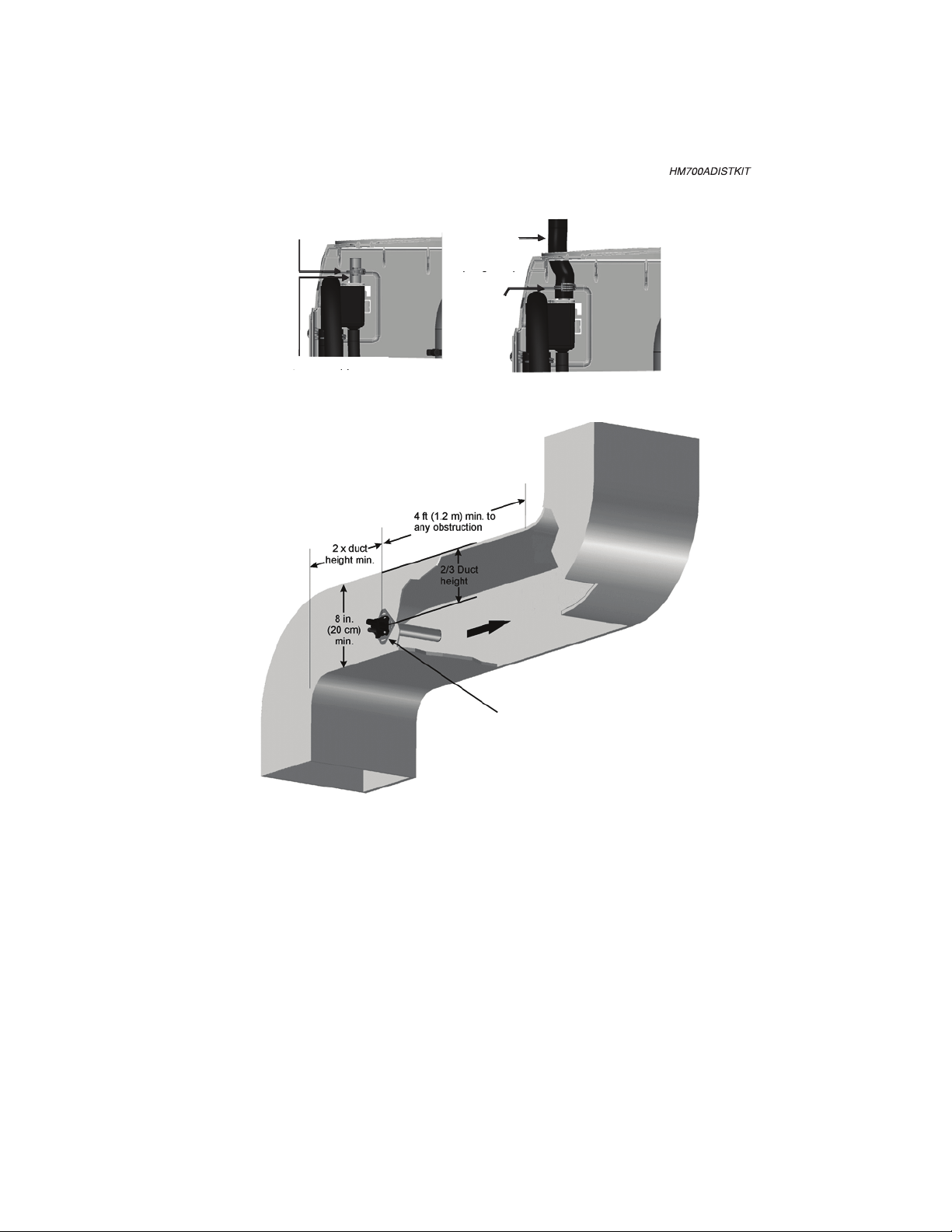

5. Horizontal runs of steam must rise 2 in. per foot

(10º) when flow is going upwards away from the

humidifier, or fall 1/2 in. per foot (2º) when flow is

going downwards away from the humidifier.

Condensate Return Guidelines For Main

Steam Lines

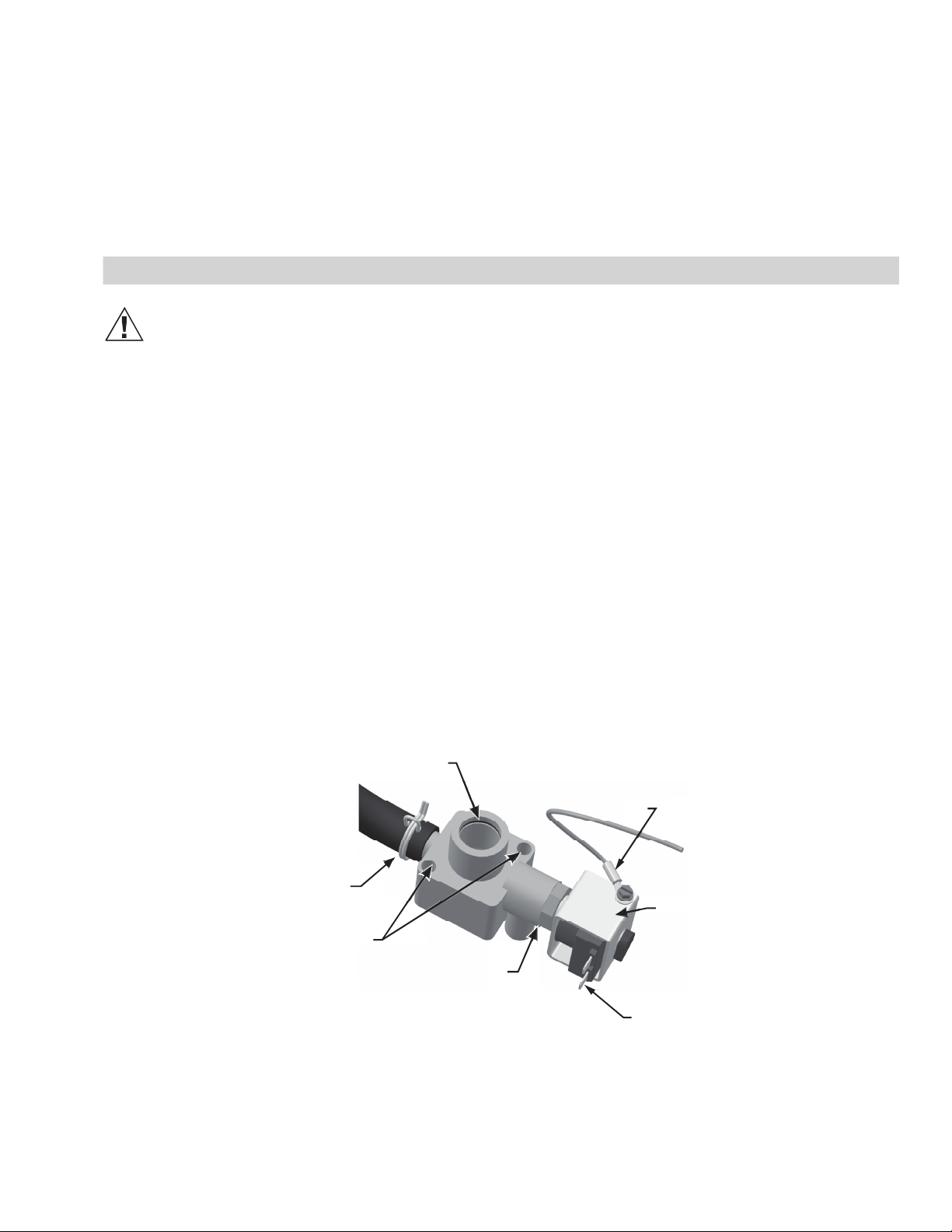

1. Use vertical condensate leg of distributor only. Do

not over-tighten clamp.

2. Condensate traps on steam mains must be located

at all low points in the system, at each elevation

change and or directional change.

3. Horizontal runs of steam must rise 2 in. per foot

(10º) when flow is going upwards away from con-

densate trap, and fall 1/2 in. per foot (2º) when flow

is going downwards towards a condensate trap.

4. In a horizontal run of the steam main, condensate

traps must be located at regular intervals.

5. The condensate trap itself is a section of piping con-

nected to the bottom of the main. A full size tee

must be used to create a condensate trap to allow

the condensate to fall away from the steam flow.

6. Vertical drop of the condensate trap should be

1.5 times the diameter of the steam main but no

less than 12 in.

7. A p-trap should be installed at the bottom of the

condensate trap. The center to center trap height

should be 2 in. greater than duct static pressure

(see Figure 1).

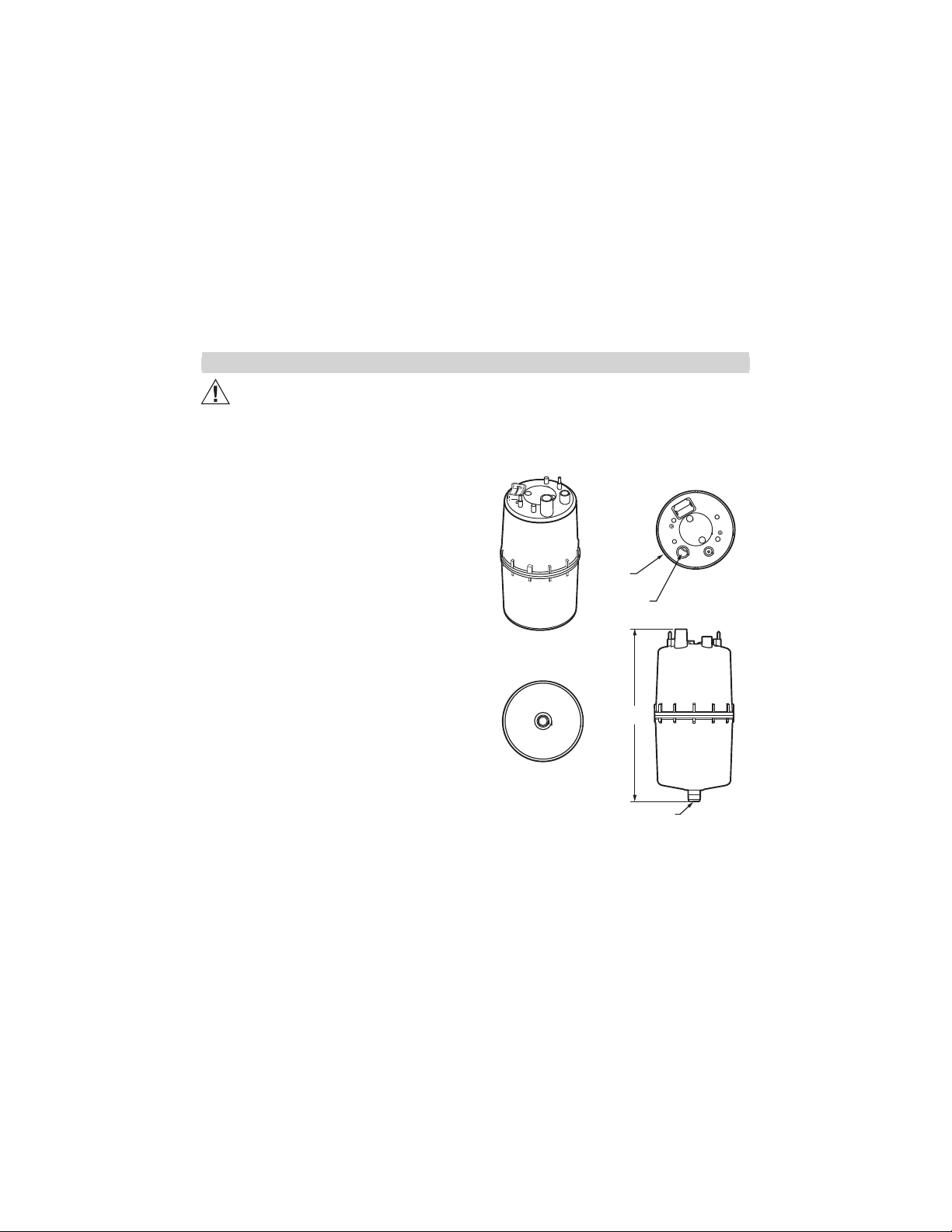

To return condensate for HM700, insert copper tube

(supplied with equipment) half way into the condensate

opening of the fill cup along with the spring clamp

(supplied with equipment).

Insert the condensate hose into the condensate return

hole at the top of the unit, and over the copper tube.

Fasten in place with the spring clamp.

Voltag e

Steam Output Material*

Maximum

Steam Line

Length Possible Losses

Minimum

Airflow CFM

Max Static

Pressurelbs/hr (kg/hr)

Steam

Hose

MED-L

Copper

Tube

Stainless

Steel Tube ft (m) lbs/hr (kg/hr)

110/120V 3.85 (1.75) 7/8 in. 3/4 in. 0.875 x

0.049W

7 (2) 0.5 (0.2) 115 3.0 in. w.c.

220/240V 7.7 (3.5) 12 (3.5) 1.5 (0.7) 230