3

1Goal of this Guide

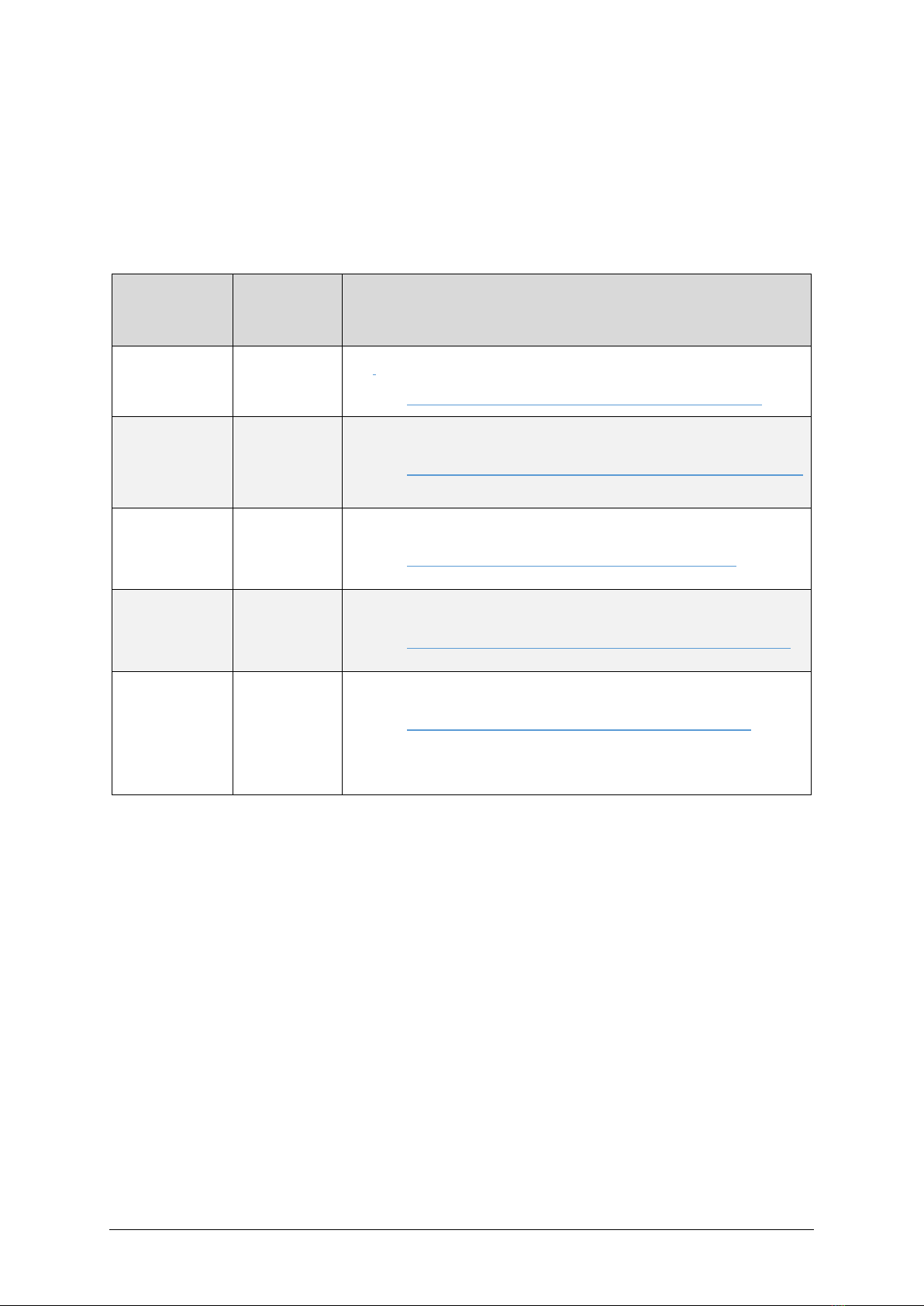

This document describes how to evaluate the KLIPPEL Controlled Sound technology (KCS) by using the

KLIPPEL QC measurement framework. The following topics are covered:

•Measuring the frequency response

•Evaluation of the performance of active systems including KCS in the large signal domain

•Evaluation of the KCS speaker protection

•Evaluation of multi-tone distortion compensation

•How to treat Rub&Buzz problems

2Requirements

Its mandatory to read the document Manual KCS Monitor.pdf which teaches necessary KCS

basic knowledge before the KCS evaluation tutorials are executed!

Hardware:

•KCS hardware platform (e.g. Nuvoton Audio Development Board (NAD), Klippel Analyzer 3

(KA3), APE Evaluation Board etc.)

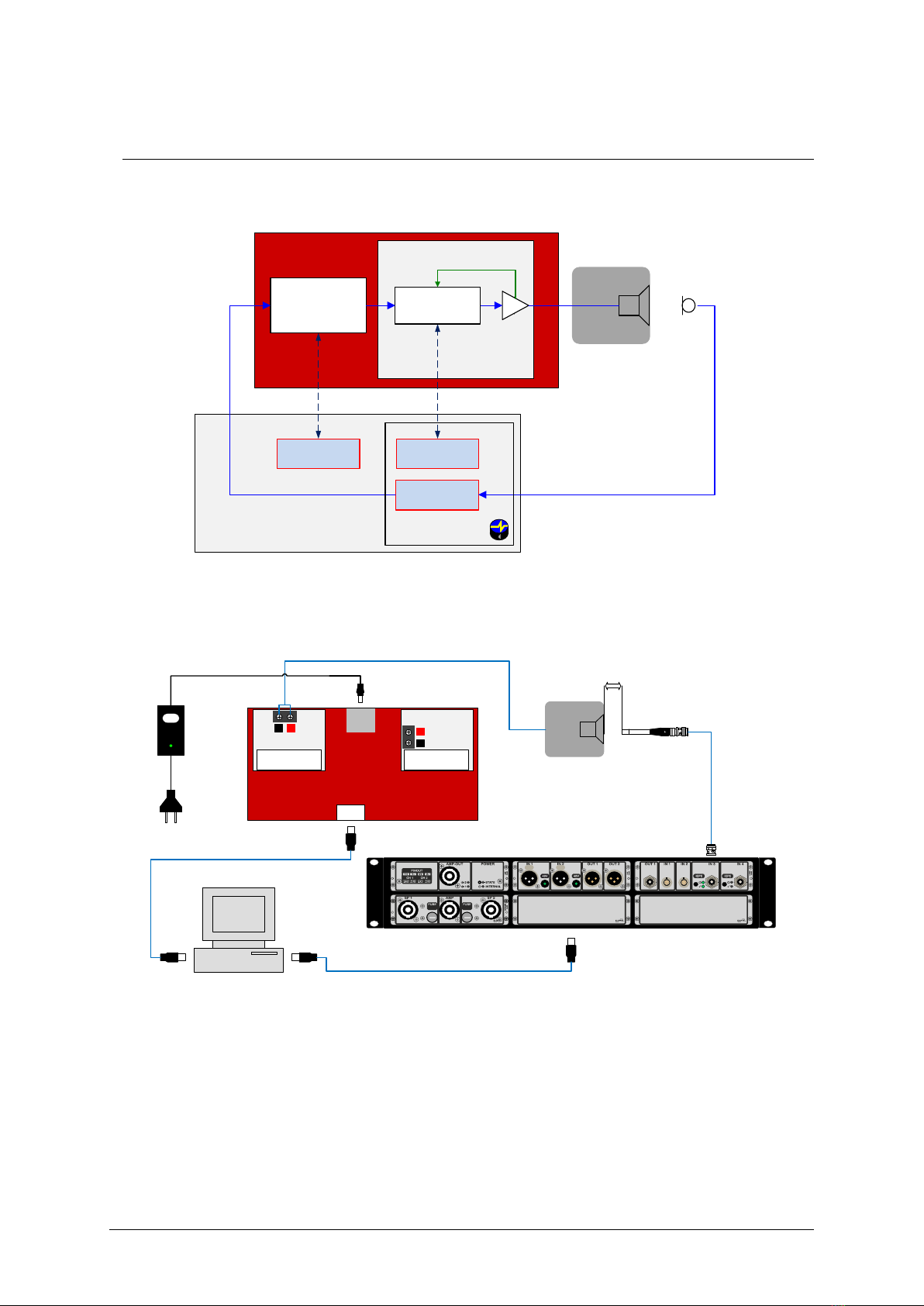

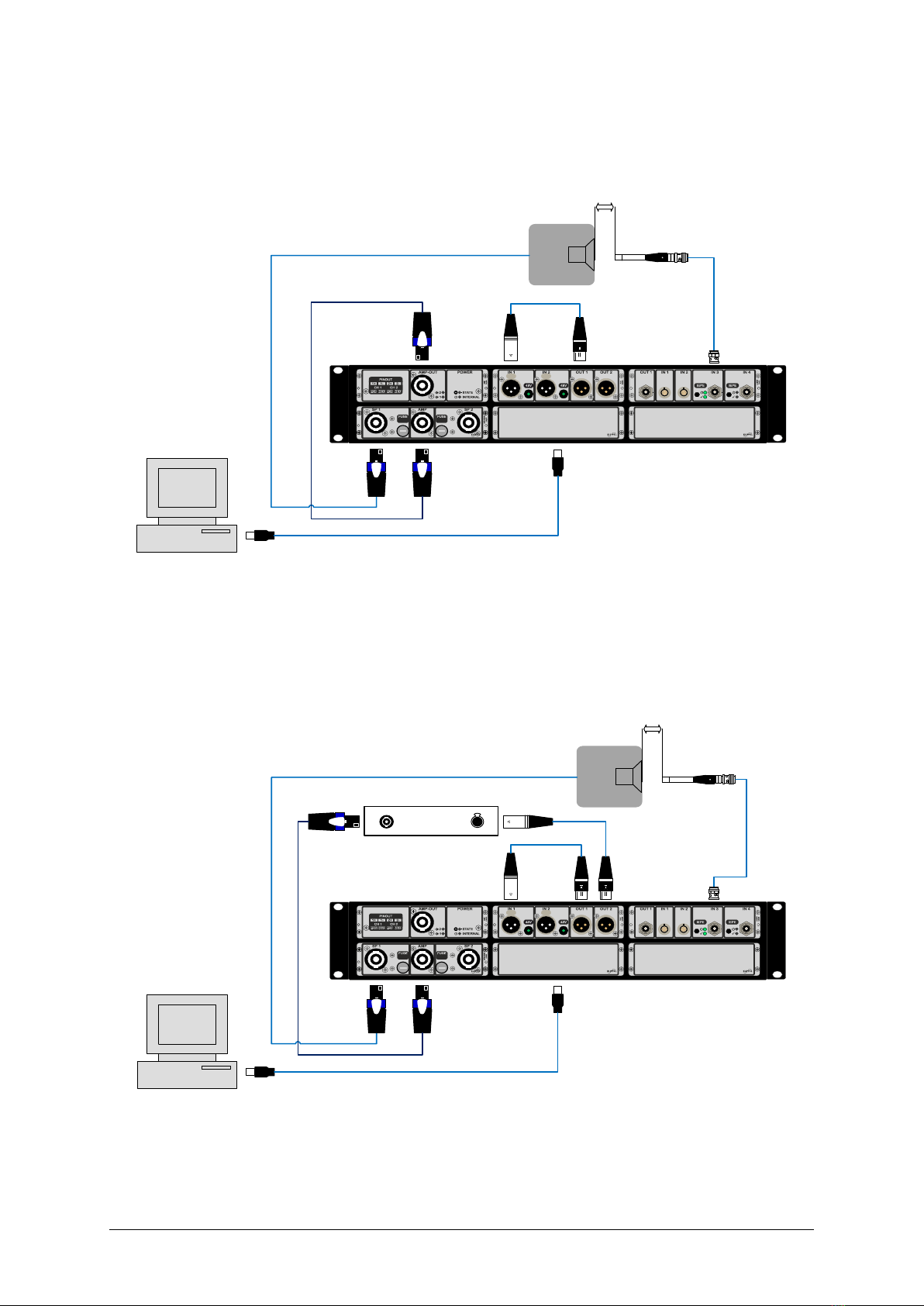

•Measurement Equipment. There are two options:

oKA3 measurement device:

▪Klippel Analyzer 3 (KA3)

▪Microphone

oNAD on-board microphone (DMIC):

▪Klippel Dongle

▪DMIC module mounted on NAD board

Software:

•Klippel dB-Lab of version >= 210.826

•Licenses for: QC Standard 6 for KCS, SPL task, Multi-tone distortion task, SYN, 3DL

•Additional License (only for QC measurement with NAD board DMIC): QC no PA hardware

required (== QC Standalone)

In addition, following Klippel dB-Lab operations are required:

•KCS Monitor operation comprising initial data for the particular DUT

•QC operation template KCS Evaluation Template.kdbx