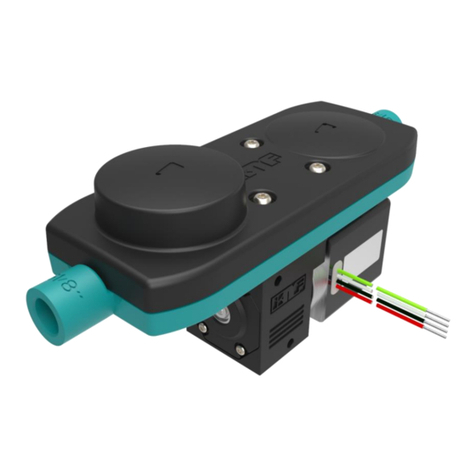

Stepping motor diaphragm metering pump FEM 1.02 / FEM 1.09 Assembly and function

KNF Flodos AG BA_FEM1-02_1-09_EN_07_157639.docx

Translation of Original Operating and Installation Instructions 10

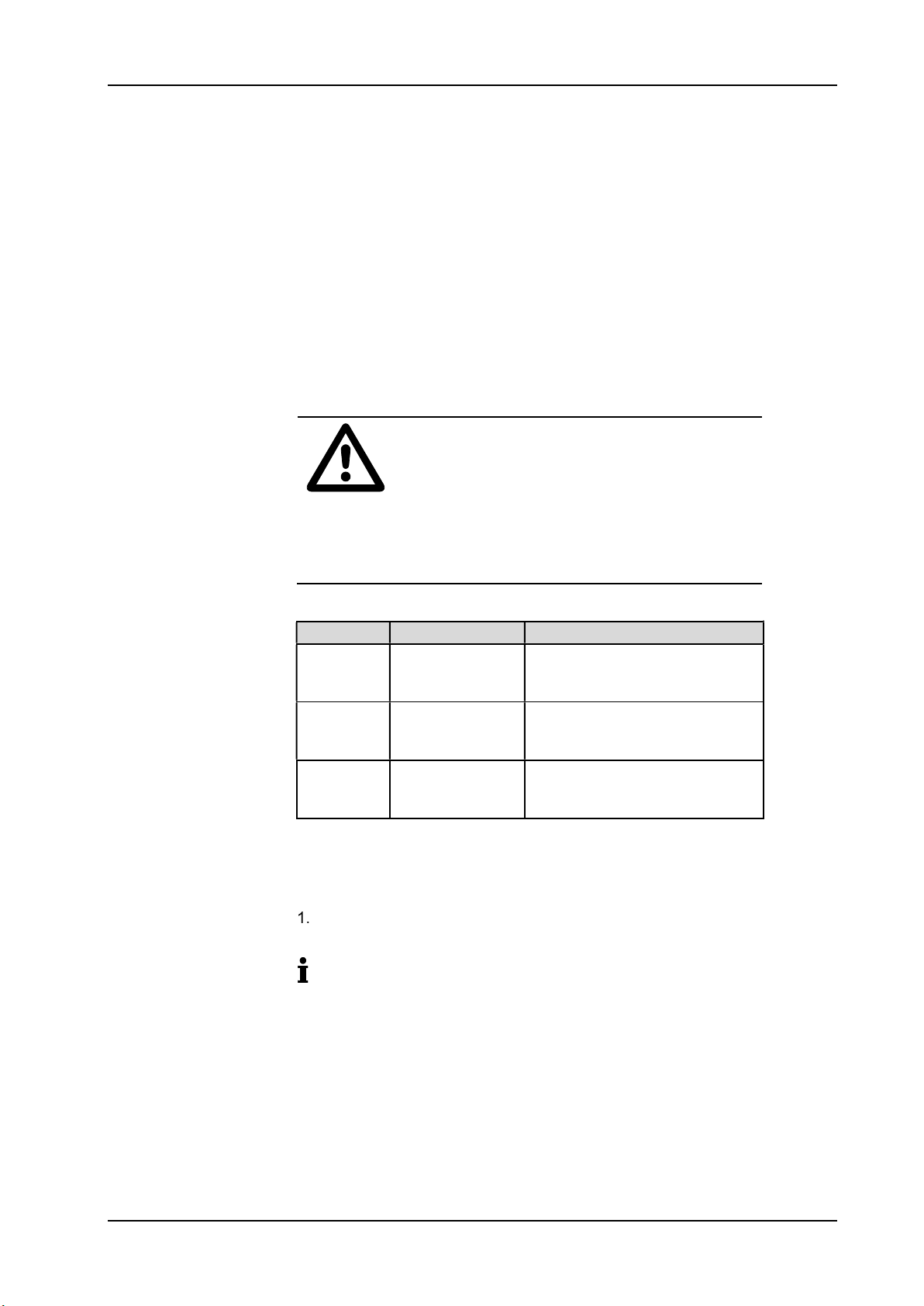

FEM … -Version (standard version)

This pump type represents this product in its simplest form and is intended for

continuous delivery at an exact delivery rate.

FEM … .27-Version (with overpressure limitation)

If the metering pump is operating against a closed system, the delivery pres-

sure quickly exceeds the maximum permissible values. To prevent this hap-

pening, an overflow valve is integrated in the top part of the pump head. If the

pressure exceeds the variable limit range (min. 0.5 to max. 6.0 barg), the

valve opens and the liquid circulates from the pressure side to the suction side

via an internal bypass system. This prevents any further rise in pressure.

FEM … .55 version (with single-stroke metering)

The .55 version was specially developed for the KNF stepping motor partial

stroke controller FE Z5. The pumps have a Hall effect sensor for determining

the position of the diaphragms. This is needed during partial stroke metering

or with customer-specific operating profiles.

Please note:

The FEM … .55 is compatible with KNF controllers FE Z4

and FE Z5.

The FE Z5 stepping motor partial stroke controller from

KNF can only be used in combination with the FEM ... .55.

FEM … .55 RC version (single-stroke metering incl. controller)

In the .55 RD version the FE Z5 stepping motor partial stroke controller from

KNF is integrated in the pump and is supplied as a single unit.

Detailed information can be found in the relevant operating instructions.

The stepping motor controllers from KNF are available as accessories, see

accessory list in chapter 10. Two different controllers are available.

Stepping motor controller FE Z4 2-phase stepper

standard controller, single speed controller for variable delivery volume,

pulse input for maximum programming capability etc.

Stepping motor partial stroke FE Z5 Dispense

partial stroke controller, partial stroke metering using potentiometer or an-

alogue signals possible, alarm output etc.

More information about the functionality of the KNF controllers FE Z4 and FE

Z5 can be found in the relevant operating instructions.

FEM ...

FEM ... .27

FEM … .55

FEM … .55 RC

KNF stepping motor

controller