Table of contents

1 About this document ............................................................................. 4

1.1 Using the operating and installation instructions........................... 4

1.2 Exclusion of liability....................................................................... 4

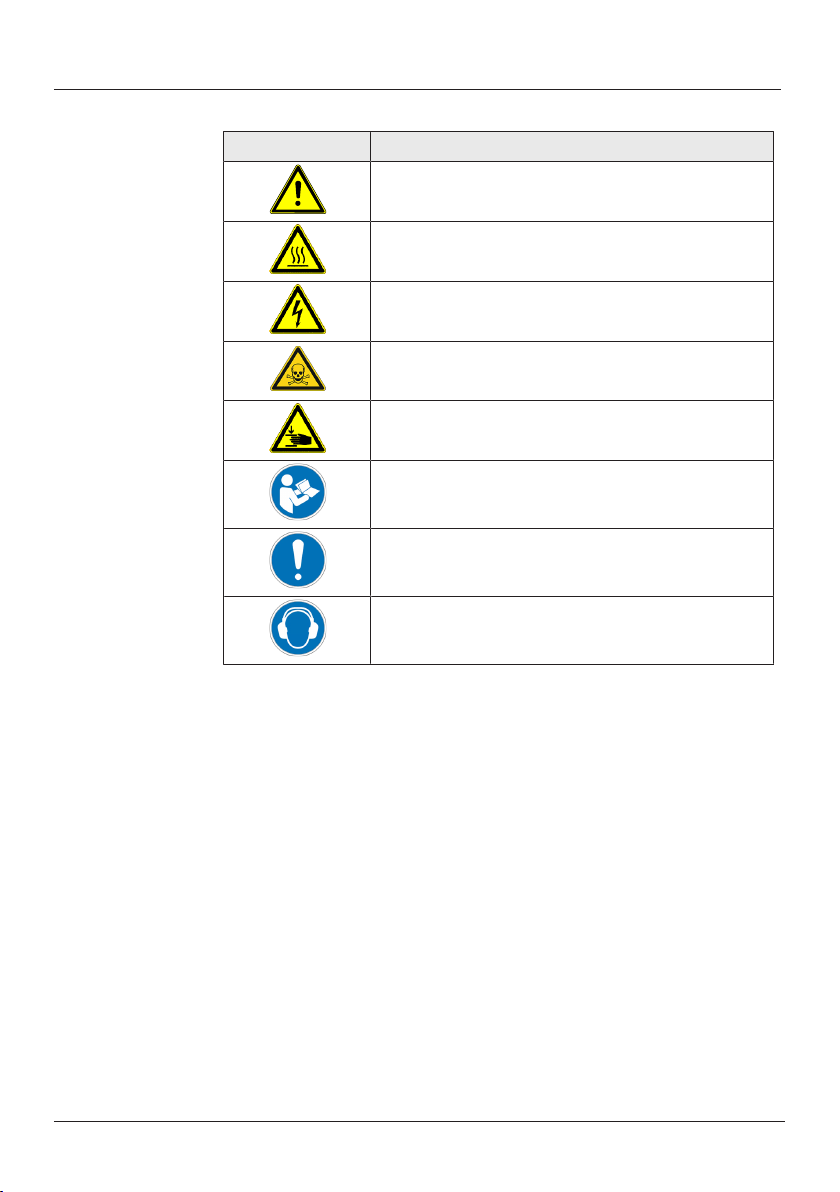

1.3 Symbols and markings.................................................................. 5

2 Safety .................................................................................................... 7

2.1 Personnel and target group .......................................................... 7

2.2 Responsibility of the operator ....................................................... 8

2.3 Working in a safety conscious manner ......................................... 8

2.4 Operating conditions ..................................................................... 9

2.5 Media ............................................................................................ 9

2.6 Use.............................................................................................. 10

2.7 Directives and standards ............................................................ 11

2.8 Customer service and repair....................................................... 12

2.9 Disposal ...................................................................................... 12

3 Technical data..................................................................................... 13

3.1 Technical data............................................................................. 13

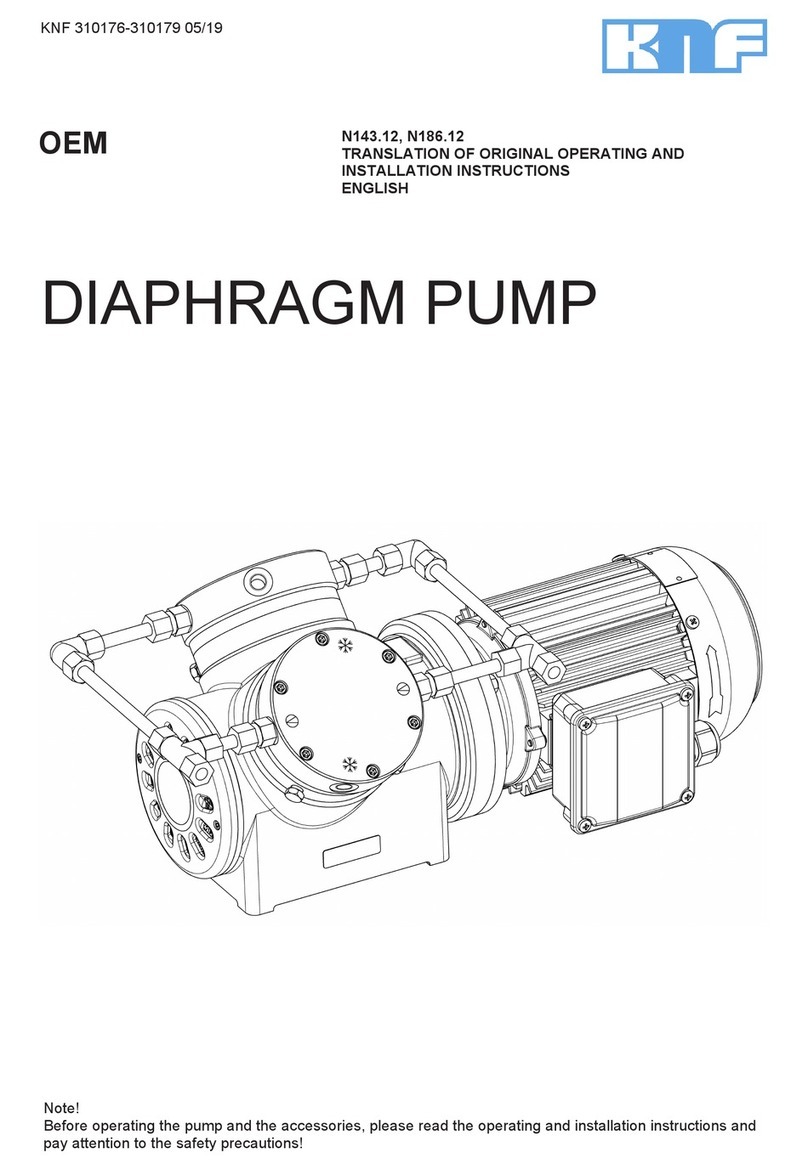

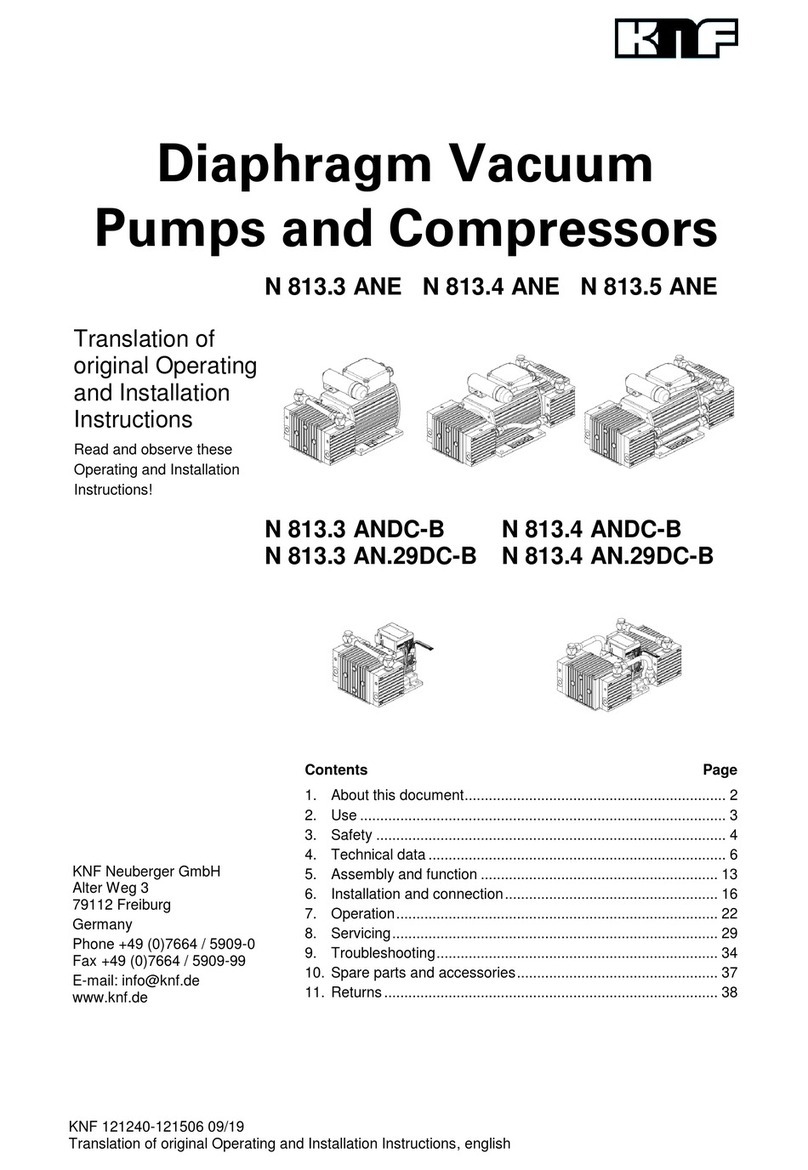

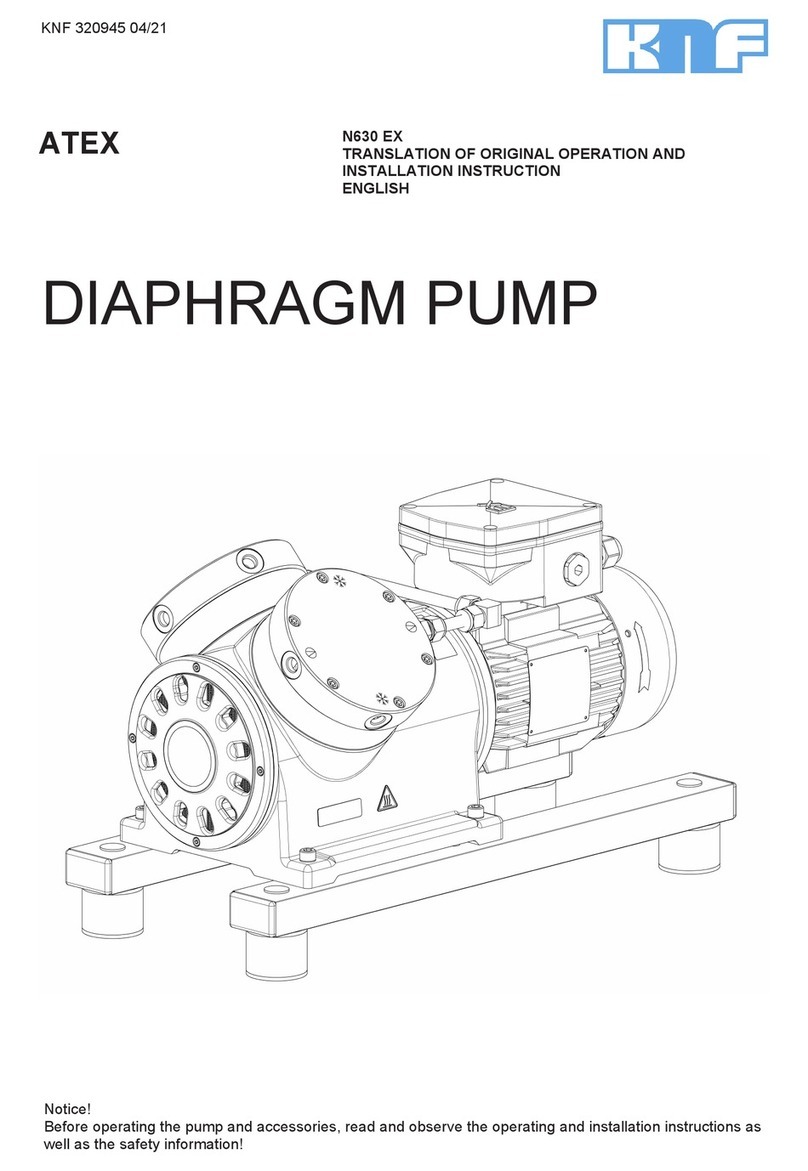

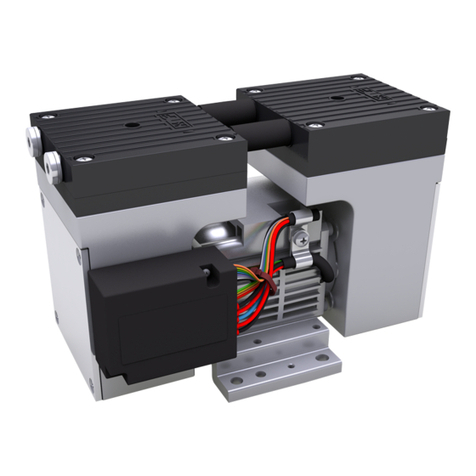

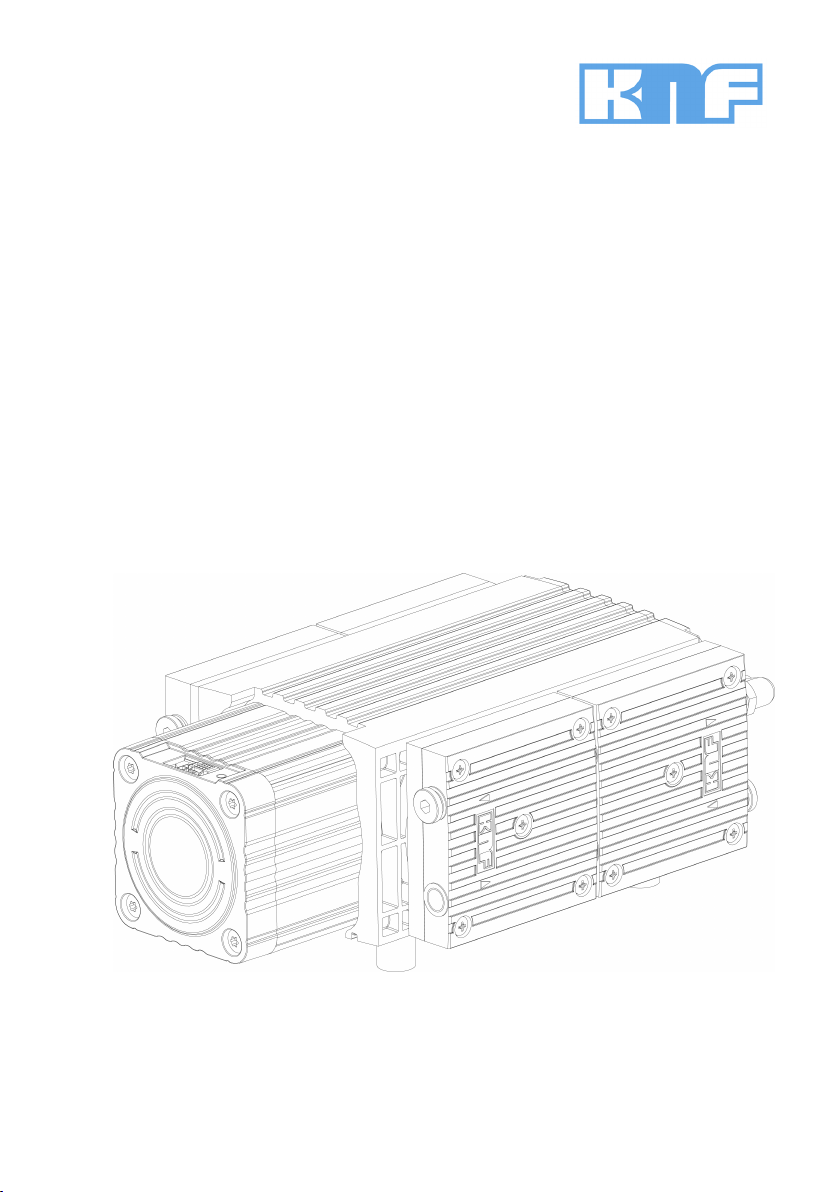

4 Product description ............................................................................. 16

5 Transport............................................................................................. 18

General ....................................................................................... 18

6 Installation and connection.................................................................. 20

6.1 Installing the pump...................................................................... 20

6.2 Electrical connection ................................................................... 22

6.3 Pneumatic connection................................................................. 24

7 Operation ............................................................................................ 25

7.1 General ....................................................................................... 25

7.2 Information on switching the pump on and off ............................ 27

7.3 Supply connector ........................................................................ 28

7.4 Signal connector ......................................................................... 29

7.5 Speed specification..................................................................... 31

7.6 Extended parameterization and functions of the pump............... 35

7.7 Error management ...................................................................... 38

8 Servicing ............................................................................................. 39

8.1 Servicing schedule...................................................................... 39

8.2 Cleaning...................................................................................... 40

8.3 Replacing the diaphragm and valve plates ................................. 41

9 Spare parts and accessories............................................................... 50