Electrical Water line Drain line

- 120V 20 AMP circuit or

- 240V 10 AMP circuit (not field

convertible)

20 psi flow pressure 140 deg. F

3/4” FPT on machine 1-1/2” MPT on scrap accumulator

5. Place the dishwasher at the spot desired for

normal operation. Level the dishwasher using

adjustable bullet feet at the bottom of the legs.

Install spray arms included in the accessory box.

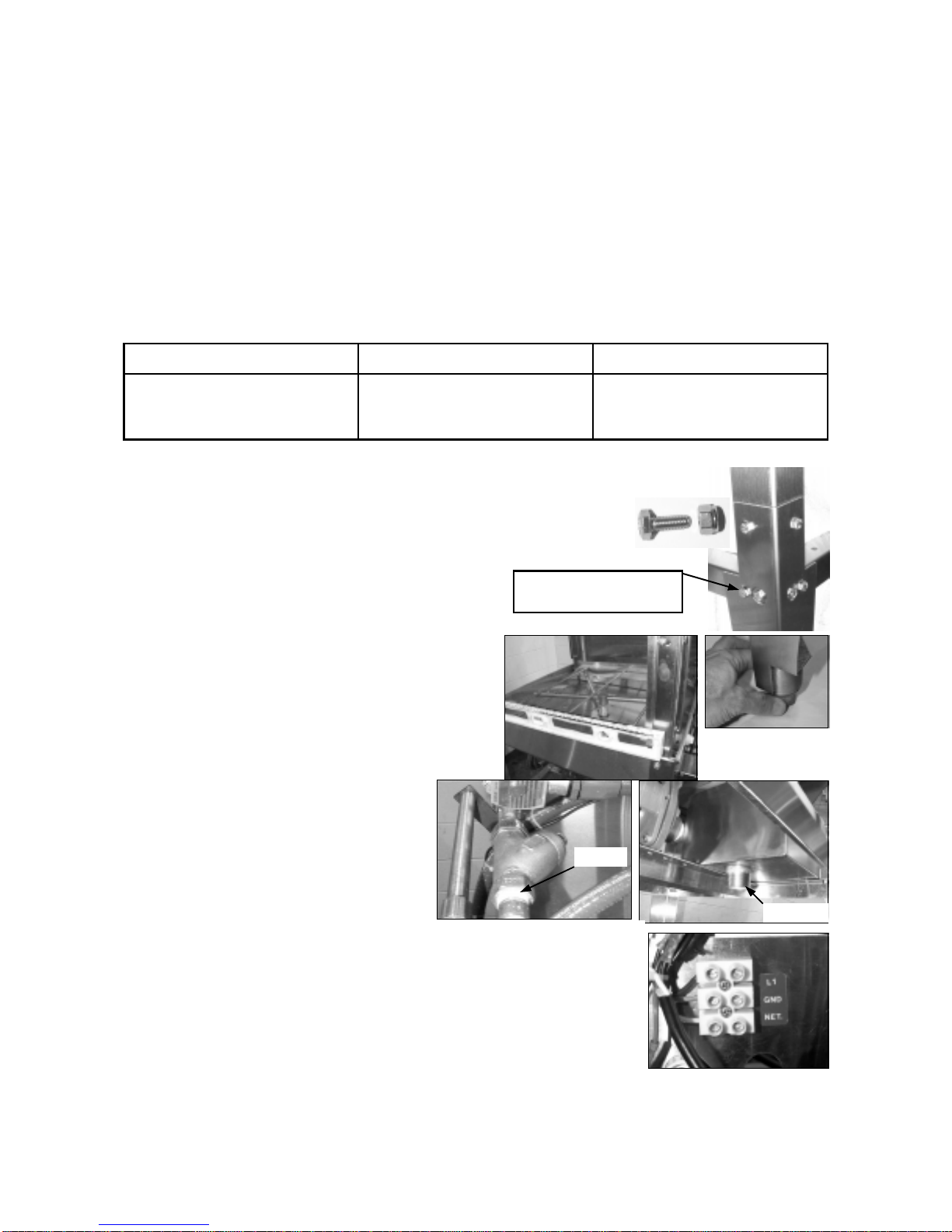

6. Connect hot water supply line to the 3/4 FPT

line strainer at rear of machine. Ensure that wa-

ter pressure is sufficient for fill (approx. 10

GPM flow @ 20 psi.). Connect drain to 1-1/2”

MPT nipple on scrap accumulator.

7. Make electrical connections (refer to data plate for voltage and current ratings)

to the labeled barrier provided at the inside back of the control box. Run all elec-

trical wire through suitable conduit and insure all connections are made in accor-

dance with local wiring codes. It is recommended that the circuit breaker carrying

the dishwasher load have NO OTHER ELECTRICAL DEVICES connected.

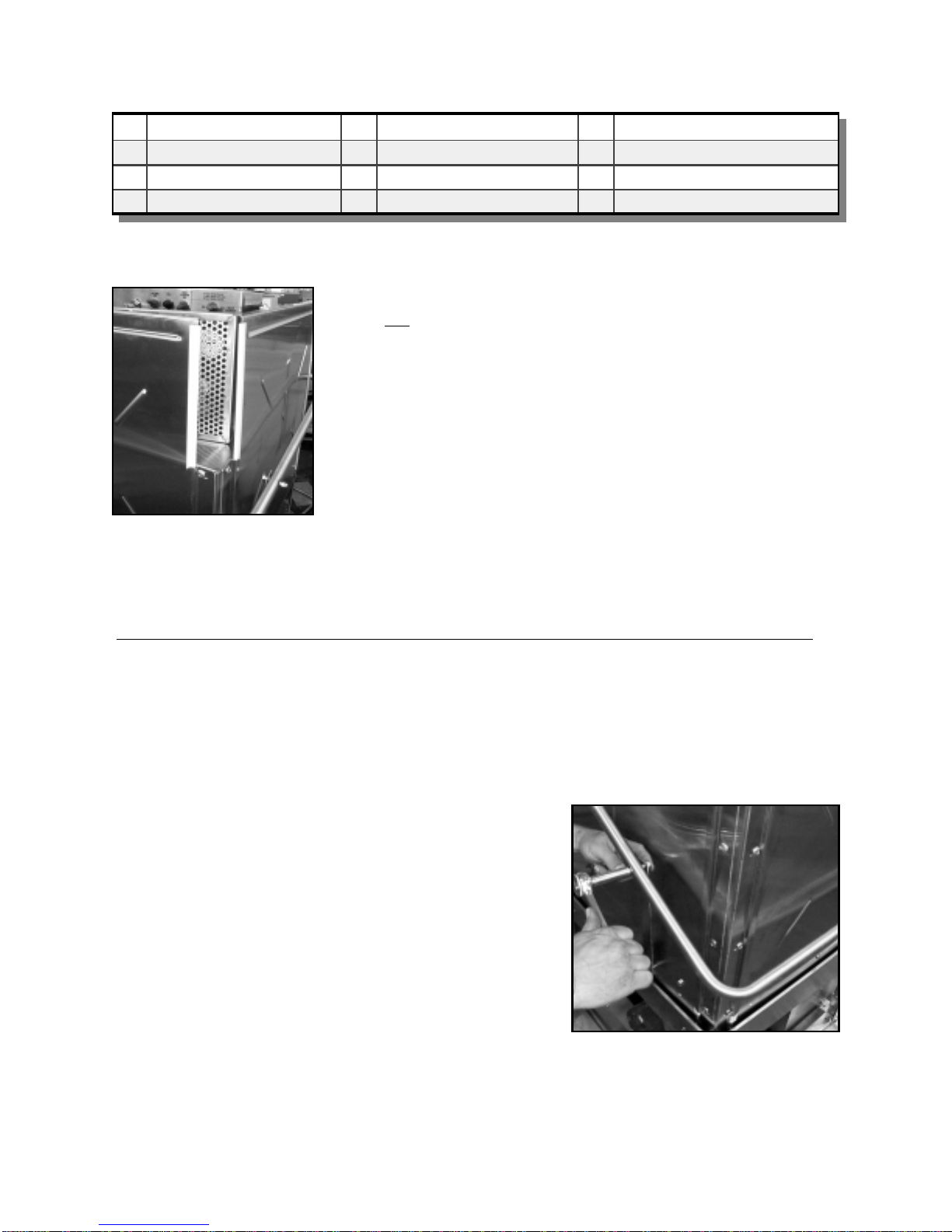

8. Attach prewash and drying tables to the dishwasher, insuring that sufficient

space is provided for the dishwasher operator. Insure that adjustable legs on

prewash and drying tables have been adjusted for proper drainage of water.

INTRODUCTION

The KLE 175 GT dishwasher is designed to provide years of excellent warewash results under many types of

conditions. Each unit is configured as an automatic start dishwasher, meaning that the dishwasher starts when

the doors are closed. The dishwasher includes a three product chemical dispenser located on top of the dish-

washer which dispenses liquid detergent, rinse product, and a chemical sanitizer suitable for low temperature

(recommended 140 deg. F applications.) Options and additional features are also available. Contact your near-

est Knight representative for more details.

INSTALLATION - Caution – Access into electrical enclosure must be performed by authorized personnel.

1. Inspect the dishwasher upon initial receipt. Lift the door arm and open the accessory package located inside

the dishwasher. Note that it includes spray arms and other equipment required for installation.

2. Examine the spot where the dishwasher is to be operated. Insure that all electrical and plumbing connections,

as well as dish table placement have been considered for installation. Parameters:

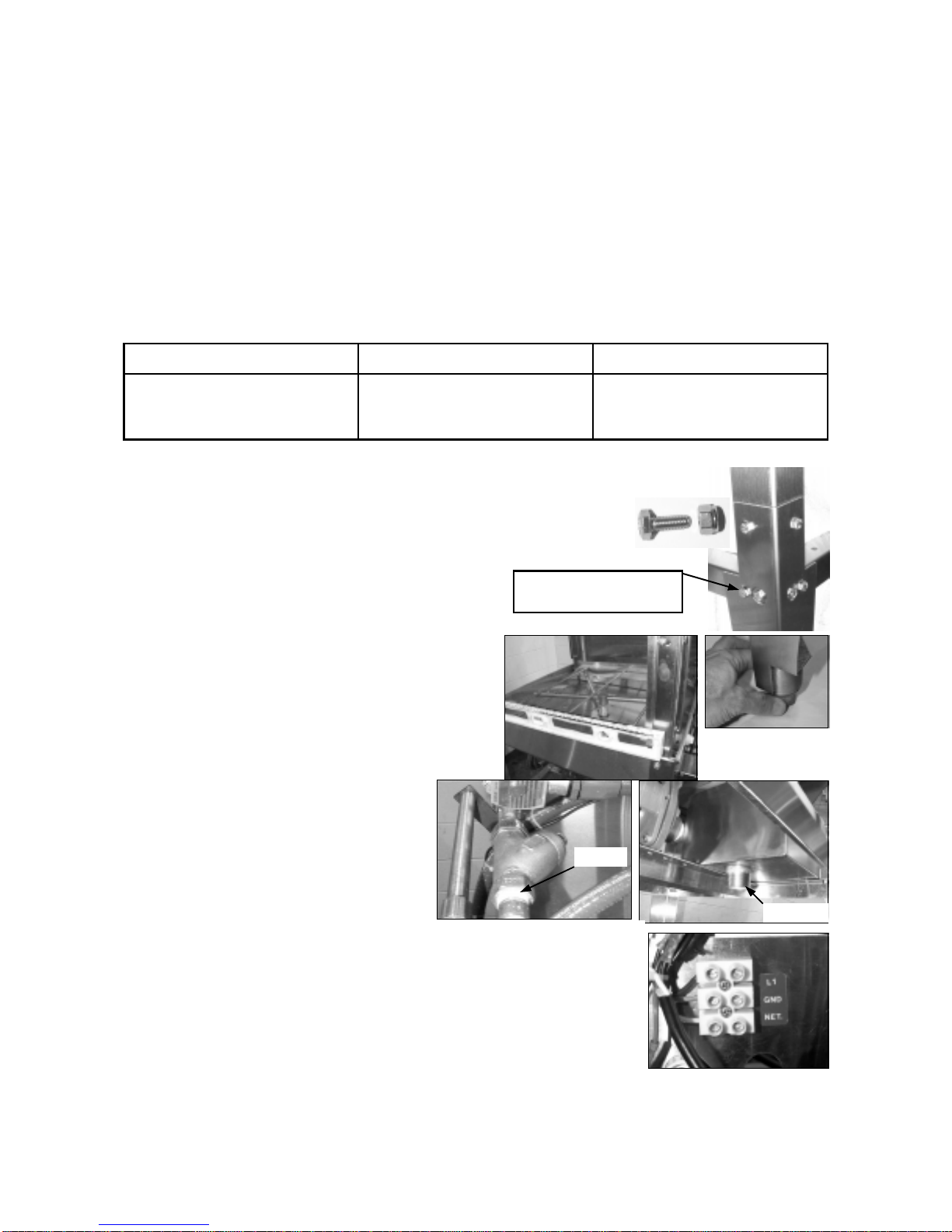

3. Install leg extensions. Each leg requires 4 bolt assemblies, 1/4-20x1/2” long, to se-

cure legs to dish machine. Bolts are located in the accessory kit envelope and on

stand. This job requires two people. Lean the machine back and install two leg

extensions, lean the machine in the other direction and install the other two legs.

Page No. 1

3/4 FPT

1-1/2 MPT

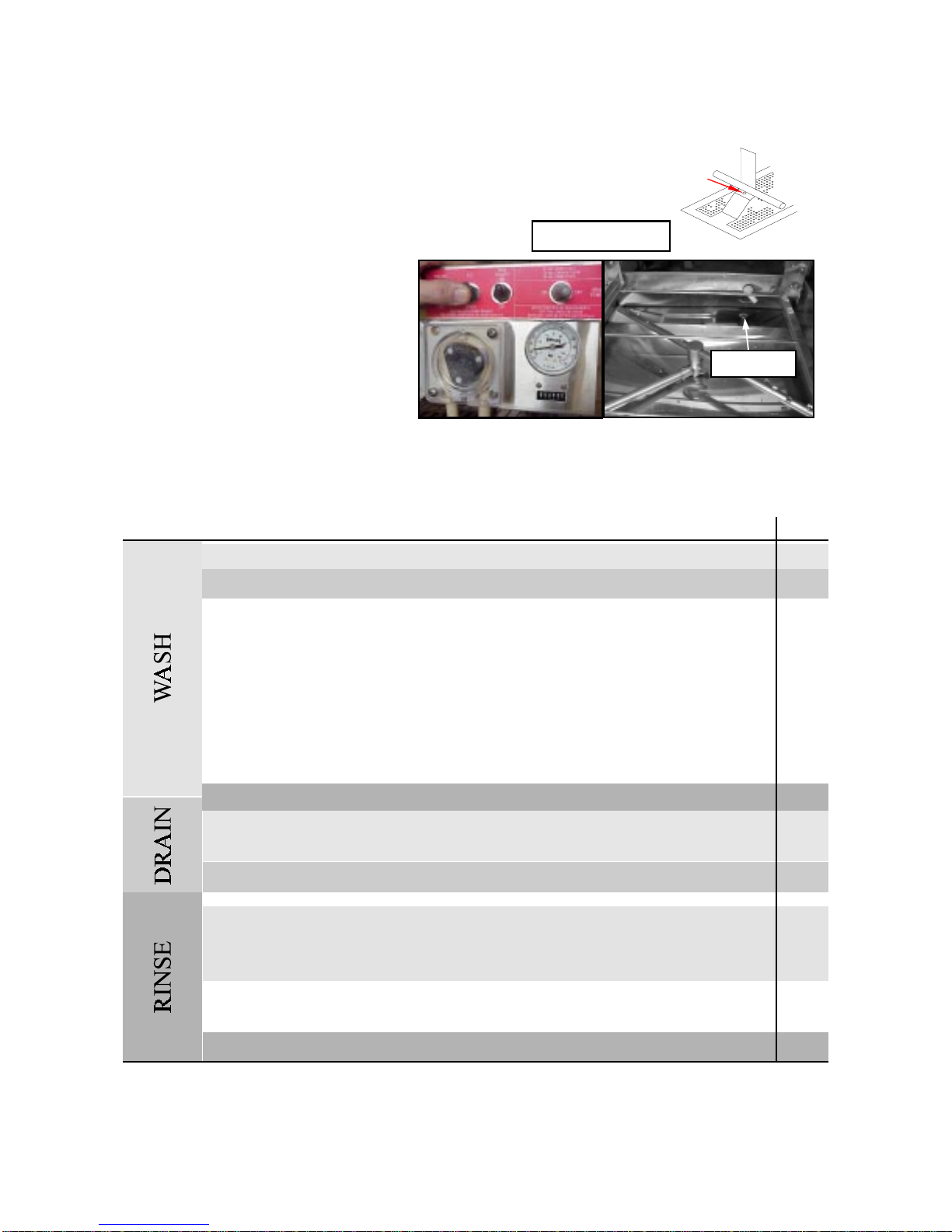

4. Install detergent, sanitizer, and rinse tubing to the peri-

staltic pumps. Use the provided hose clamp ties to secure

delivery tubing to squeeze tubing. Feed outlet tubing to 70

deg. elbow on side of pan directly over the sump. Tubing

installation is easier if done before tabling installation.

Attached to stand, remove and

reinstall to attach legs

(11/10/01) Revision F, EO 4109 Part No. 9641606