Connection marks of motor are as follows:

L1, L2, L3, N: Network access, phase sequency free, (check the voltage in rating plate)

PE: Protective earth

11 and 14: Running indication (n > 200 rpm)

E1: Analog guideline value for rotation speed (0...10 V or PWM)

D1: Digital input, enable device

GND: Voltage reference

10 V: DC output, max. 10 mA

24 V: DC output, max. 70 mA

Ru = Brown

Si = Blue

KeVi = Yellow/Green

Va = White

Mu = Black

Ke = Yellow

Vi = Green

Pu = Red

The motor needs a rotation speed set point for running. It can be formed of the 10V output of the motor. In

cold surroundings the heating of electronics is activated when the inside temperature is -19˚C. That is why it

is very important that the motor supply is never switched off. The motor can be stopped by means of control

or by disconnecting the enable device. To prevent the impeller and motor from freeze-up, it is advisable to

let the motor always run at least at the minimum speed (1.0V control).

If the motor rotates freely e.g. in air flow, it may generate a voltage of more than 50V to connectors.

Rotation of impeller has to be prevented and dead state has to be checked always before service works.

Electornics of motor includes big condencers which may be dangerously live even after switching off the

voltages. Wait at least three minutes after the disconnection of voltage before you start service or repair

works.

Mains voltage must absolutely be the same as given in the rating plate. Motors have integrated overload

protection. Maximum value of fuse for all models is 10A.

Maximum leakage current of the unit is 3.5 mA in mains conforming to the standard DIN EN 60990.

Commissioning and operation

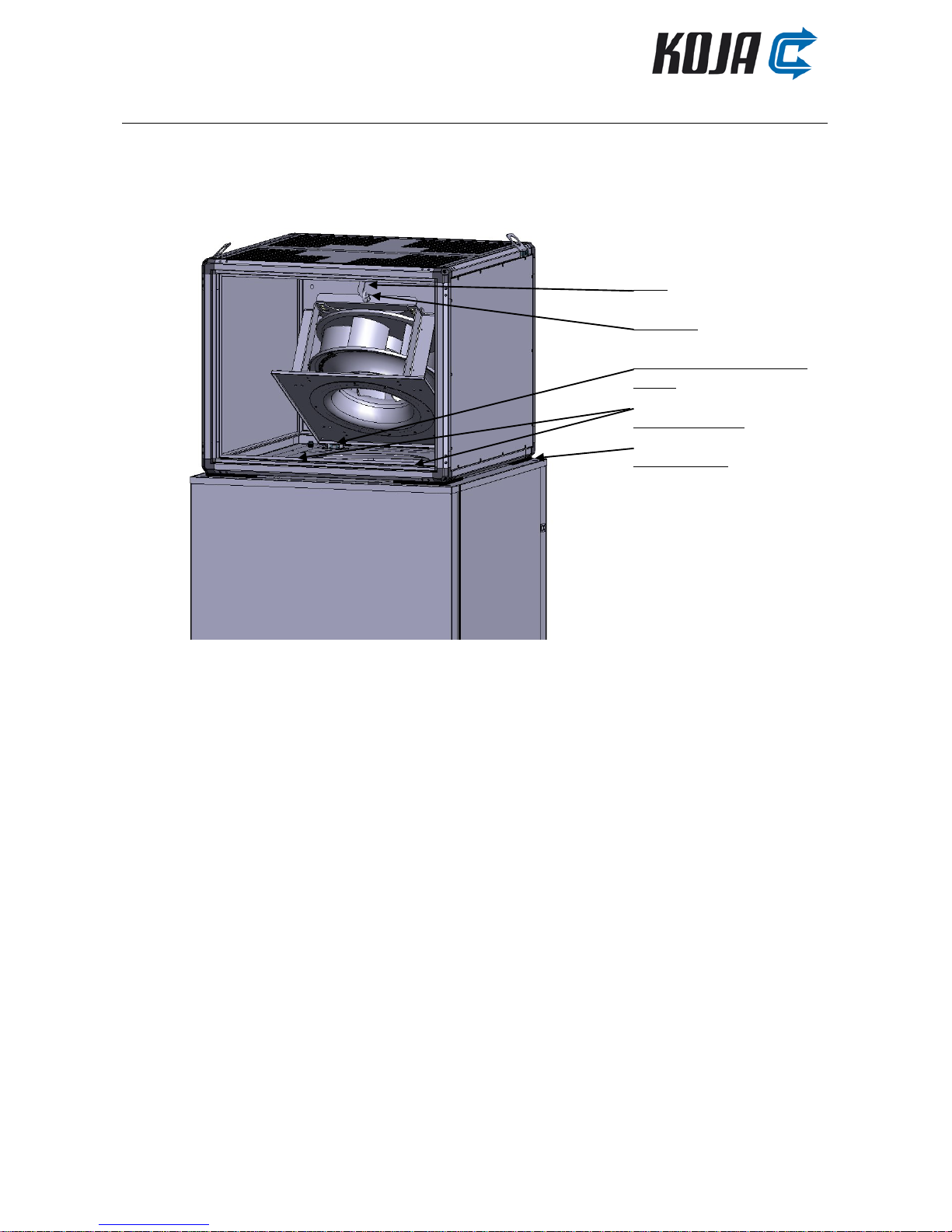

Make sure that the roof extractor has been installed according to the instructions, and that there are no

foreign objects loose inside.

Also check that the electrical connection has been made according to the instructions enclosed in the

delivery.

Make sure that the fastening screws are tight enough in the stack and there is a raising rubber in every corner.

Start the extractor and make sure the impeller rotates in the direction indicated by the arrow marked on the

mounting plate.

Make sure that the base plate is tightly fixed on the mounting surface of the mounting stack.

8