5

Noise:

Ear mu should be worn to protect the ear from sparks and molten metals and to prevent hearing loss from

the arc welding machine noise. When the noise in the working environment reaches a level that is disturbing

and causing headaches, an auditory problem may occur. In this case, your ear mu should be worn

immediately. Hearing loss may not be noced unl the test is performed and it may be too late for treatment.

Importance and Cleanliness of the Work Environment:

The order and cleanliness of the working environment are as important as servicing the welding machine. In

fact, the degree of damage can be mulplied by the number of people in the environment. Although any

warnings on the machine have been read and the necessary precauons have been taken, any of the people in

the vicinity may be caught in the work area, causing a risk of electric shock, hot metal contact, or falling.

All equipment, cables, hoses and gas cylinders must be kept away from moving

environments such as doors, corridors and staircases. Eorts should be made

to keep the environment dy and the work environment should be cleaned

when welding is nished. In this way, besides working safety, working

eciency will increase. In addion, other workers in the vicinity of the welding

zone may be intrusively pushed into the welding bath, so a protecve screen

must be pulled around during welding.

GAS TUBE CAN EXPLODE: Use only compressed gas cylinders containing

protecve gas produced for welding. Make sure that the regulators suitable

for the gas and cylinder pressure used are correctly installed in the cylinder.

The tubes must be kept in an upright posion and secured to a xed place with the

safety chain. Never move the tubes without closing the protecve caps. Make sure

that electrodes, electrode pliers, earth pliers and any parts under tension do not

come into contact with the gas cylinder. Store tubes away from the so-called risky

areas that produce heat and sparks.

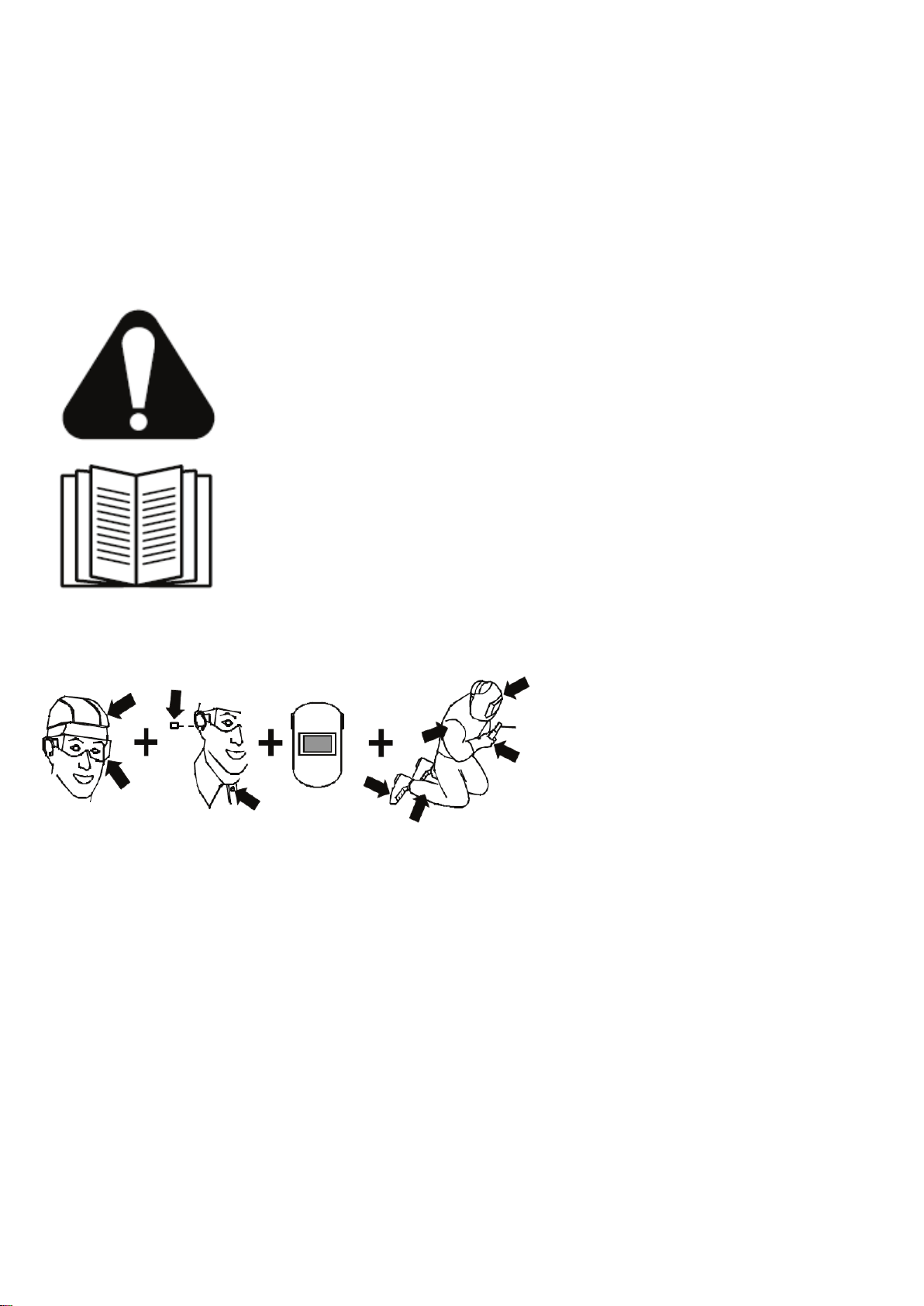

WELDED MATERIAL CAN BURN: A high amount of heat may be released during welding. Hot surfaces and

materials can cause severe burns. Gloves must be worn when touching and handling such materials.

ELECTRIC SHOCK CAN CAUSE DEATH: The risk of electric shock is the most serious

risk that the welding operator can oen encounter. Contact with electrically live

parts can result in injury, death or electric shock and sudden reex fall. Do not touch

the electrode, the ground connecon, or the live workpiece connected to the

machine whilethe machine is in operaon. Insulate yourself against the electrode,

the ground connecon or the workpiece. Do not touch the metal ends of the plug

immediately aer unplugging the machine, as there may be a risk of electric shock.

The risk of electric shock associated with the welding machine is divided into two categories:

• Primary voltage shock (example 230 - 460 V)

• Secondary voltage shock (example 20 - 100 V DC)

Primary electric shock is very dangerous as it is much higher than the welding voltage. You may experience a

primary electric shock when the power to the machine is on, your body is in contact with the ground, or you

touch a live spot in the machine. Note that turning othe ON-OFF switch on the machine alone may not be a

sucient soluon. For complete safety, the ON-OFF switch must be disconnected and the cable must be

disconnected from the connecon point aer the fuse has been switched o. Never remove the side covers of

the machine and have it checked and repaired by an authorized technician in case of malfuncon. Be sure to

ground the machine and the workpiece. Do not use uninsulated cables and pliers, replace them with new ones.

Never immerse the electrode in water to cool. Do not touch the electrode cables connected to two separate

welding machines, as the voltage may be the sum of the open circuit voltage of the two machines. Always wear

a seat belt to prevent falling from electric shock when working high above the ground.