Features & Application

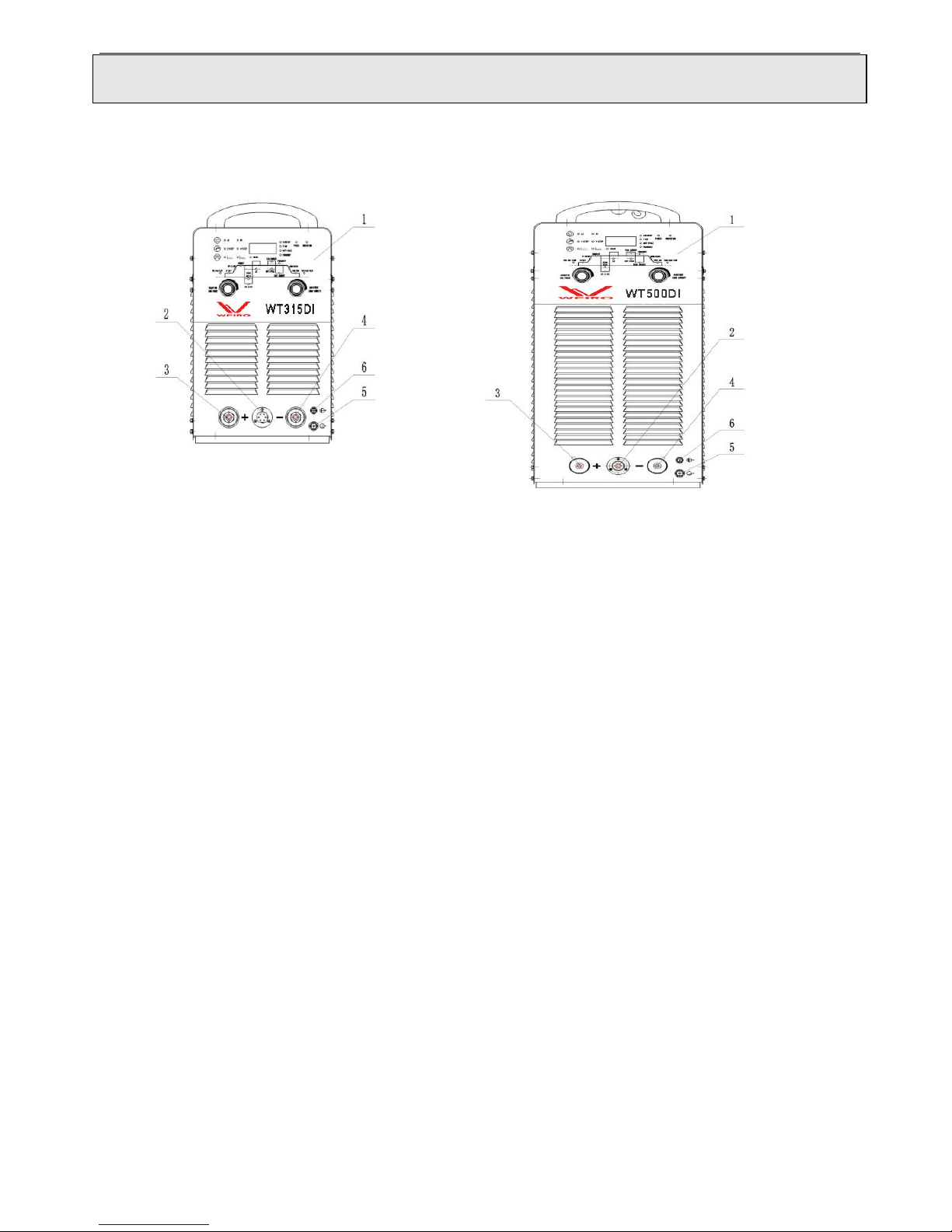

WT-DI series inverter multifunctional welding machines can be divided into three types (315DI, 500DI

and 630DI). They can perform DC constant current TIG welding, DC pulse TIG welding, square wave AC

constant current TIG welding, square wave AC pulse TIG welding, which are used for carbon steel, copper,

titanium, aluminum as well as aluminum-magnesium alloy welding. Because of reasonable static and sound

dynamic characteristic the welders enjoy, they have comprehensive operational functions.

Features and benefits:

◆Feature for AC/DC TIG welding, good looking weld, deep melting and low electrode consumption.

◆Self-diagnostic function with error code display.

◆HF soft switch transform, high efficiency, small size, light weight.

◆Multi-function, convenience, good adjustability.

◆Knob-control preset of all parameters and welding state, simple and convenient.

◆Excellent weld seam quality can be achieved due to its effect on all important areas of the weld.

◆Non-source power factor compensation technology, high PF (power factor).

◆Easy to arc-starting, stable arc, high performance.

◆Atype enjoys the synchronous mutual arc function.

◆Adjustable argon stopping time of lag, current descending time and the current of stopping arc improve

the TIG welding performance.

Applications:

◆Suitable for mild steel, Copper, Titanium, Aluminum and Al-Mg alloy welding.

◆Electric power, petrochemical Construction.

◆Boiler pressure container manufacture.

◆Shipyards.

◆Bicycle, fitness equipment, and stainless furniture manufacture.